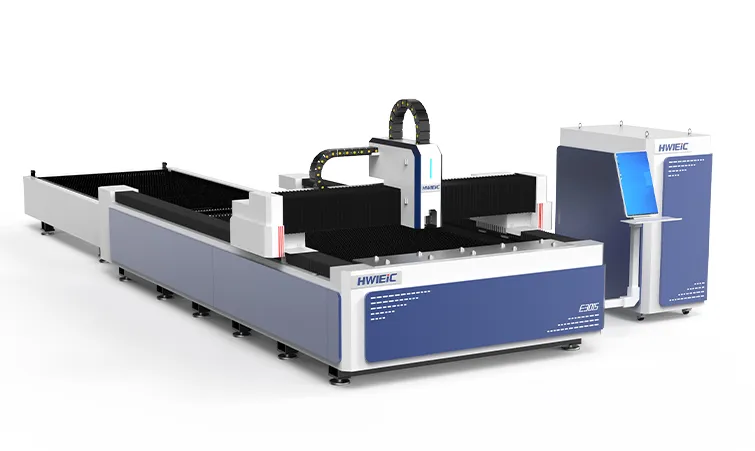

Série E

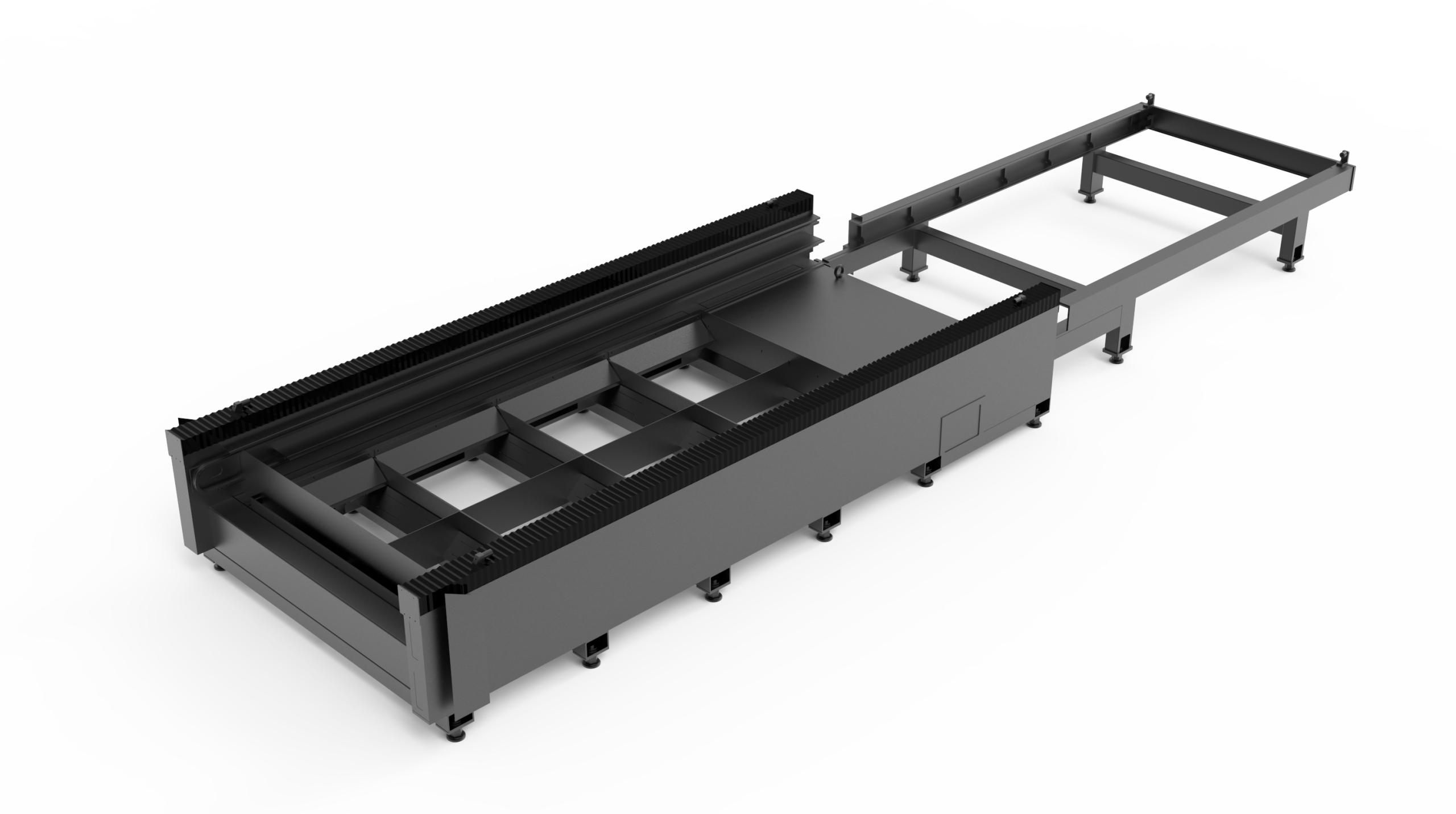

Plataforma de troca de máquina de corte a laser de fibra

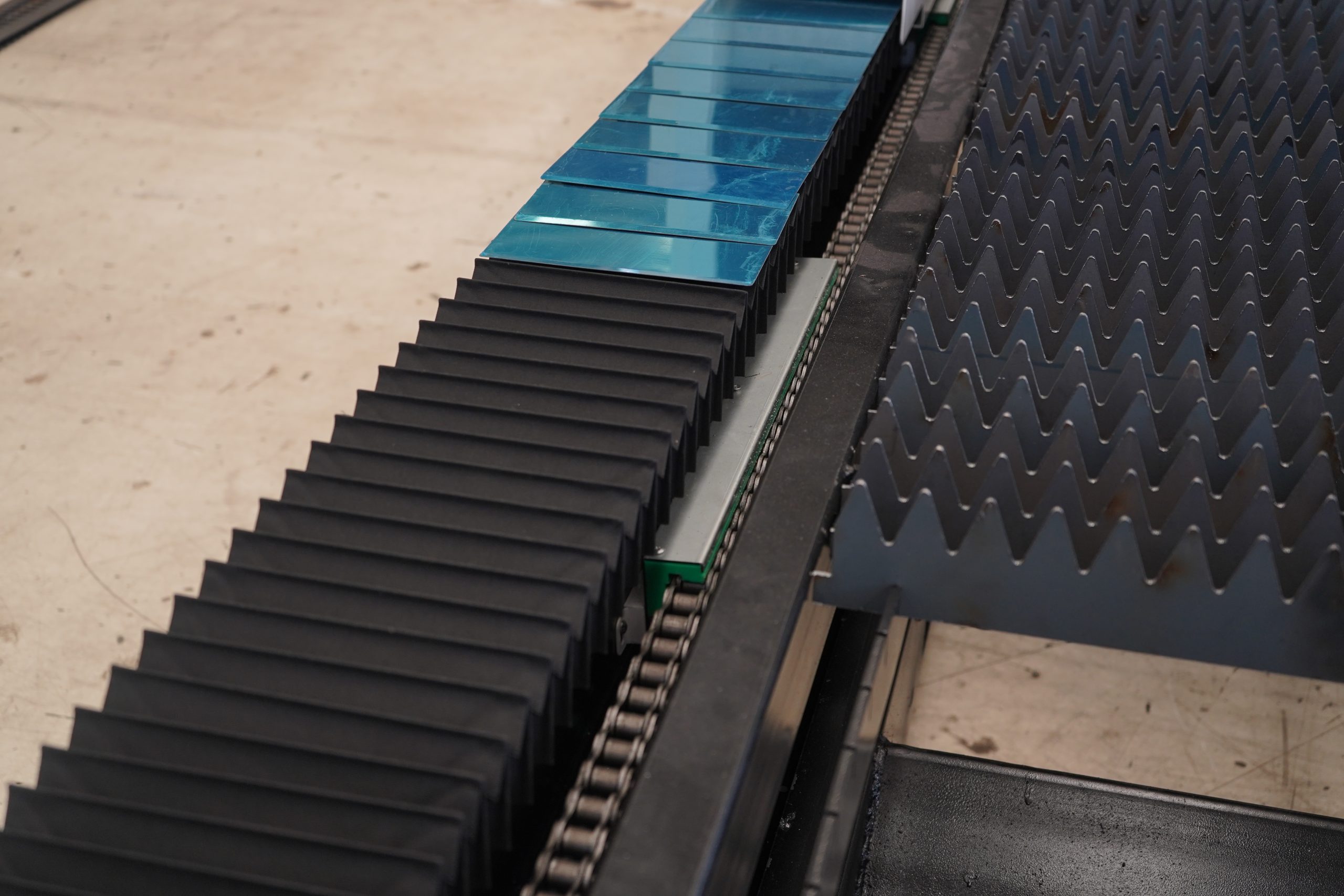

High-Speed Parallel Exchange Platformdesign, Simultaneous Exchange Of Two Worktables,Stable And Reliable Transmissior Mode, Shorter Exchange Time.

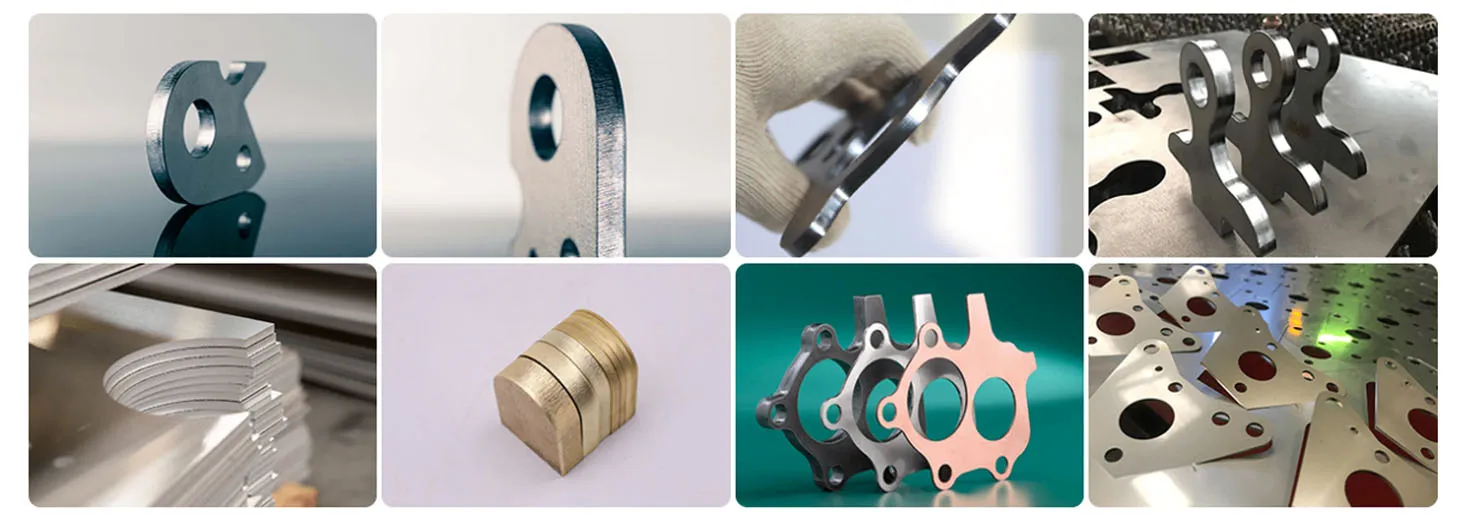

A deformação livre de corte de aço inoxidável, aço carbono, chapa de cobre, chapa de alumínio, etc. Velocidade de corte rápido, de alta precisão, corte contínuo por um longo tempo. Perfuração, abertura de canais, corte de gráficos, etc. Feixe de boa qualidade, sem rebarbas, sem escória, sem a borda preta, sem a necessidade de processamento secundário Mais estreito corte de costura, no mínimo, zona afetada pelo calor, local mínimo deformação da peça.

Este altamente rentável máquina é equipado com duas plataformas de troca, mas seu tamanho compacto pode satisfazer alguns clientes que preferem alta potência, mas a falta de espaço.

Compacta, com alta eficiência de espaço, livre de fumo corte habilitado por inteligente de remoção de poeira, e reforçado à prova de fogo de design com grafeno e vermelho cobre.

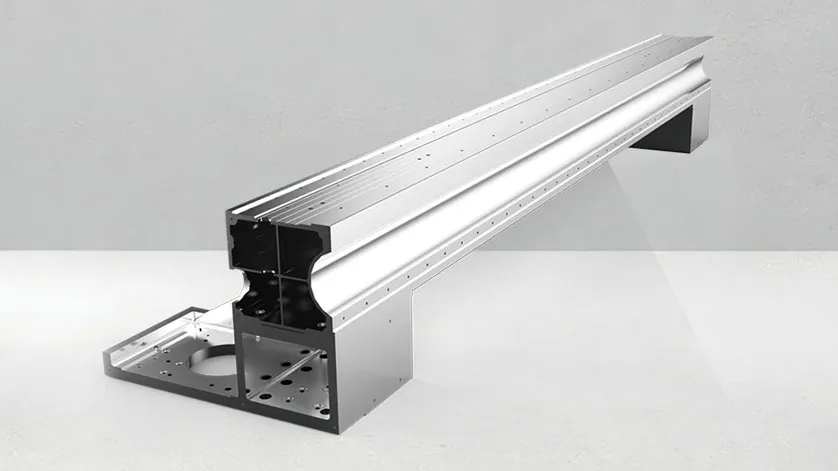

Usamos componentes eletrônicos integrados e precisão do trilho de guia e racks (fósforo de 100%) para ativar a aceleração alta (1,2 G) e precisão de posicionamento (±0,05 mm).

Mantenha a máquina ferramenta indeformable e ininterrupta, a alta temperatura, mesmo após longo tempo de uso, pois de passar por 7 padrão de processos de 600° alta de recozimento

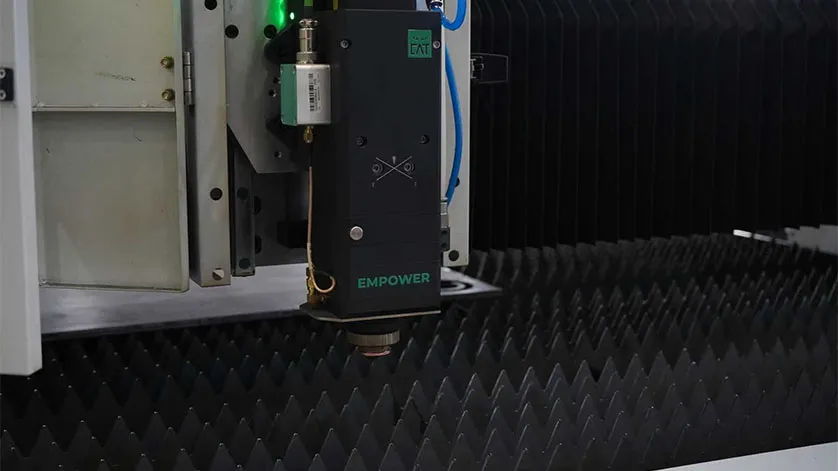

Este profissional CNC sistema é instalado internamente com muitas funções, de modo a reduzir a taxa de falha e permitir o fácil uso e manutenção.

Pequena pegada de carbono de alta eficiência—só 19m2 para libertar o total poder de corte.

Dupla troca de plataforma em formato compacto—perfeito para o limitado espaço da fábrica.

Oco de cama + grafeno/cobre proteção contra incêndio—seguro, estável, e termicamente resistente.

Inteligente espiral de remoção de poeira—permite livre de fumo, eco-amigável de corte.

Acelera até 1,2 G com micro-nível de precisão (±0,05 mm).

Industrial de trilho de guia + rack, perfeito para um movimento mais suave.

Estável sob a ação do calor—base da máquina térmico a 600°C, 7-fase de transformação.

Verde mãos de boas-vindas—interface intuitiva, fácil para qualquer um de operar.

Avançado sistema CNC, pré-instalado com o diagnóstico de automação e lógica

Deslag piercing garante aspirador de buracos e estética acabamentos.

Auto-ajuste de controle de vibração—cortes de chapas finas com impecável precisão.

Micro-conjunto de suavização—a descarga segura, limpa bordas, zero de retrabalho.

De poupança de energia da unidade de componentes de mais baixo consumo e manutenção.

Projetado para a produção sustentável com o smart poeira e controle de incêndio.

Durável em uso prolongado, a deformação livre, mesmo em 24/7 linhas de produção.

Seu design minimalista combina o seu corpo principal, armário elétrico, sistema de controle, compressor de ar, gerador de laser, e do refrigerador de água em um, de modo a reduzir o espaço de custos e melhorar o workshop de utilização.

Benefícios De Desempenho . Ele pode cortar várias folhas de metal em alta velocidade e de alta qualidade.

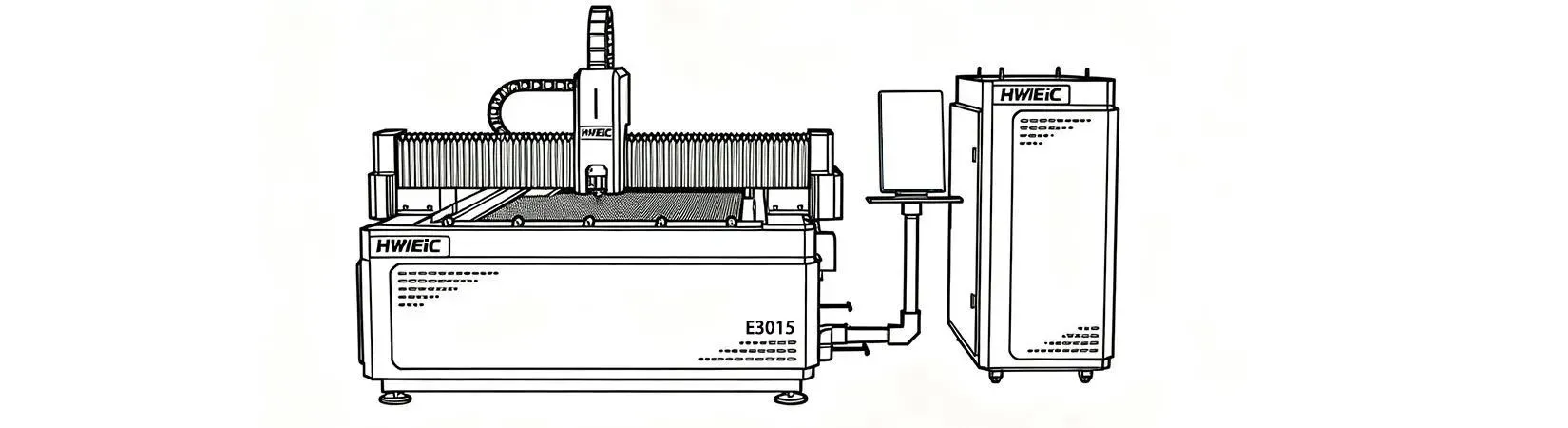

| MODELO | E12025 | E10025 | E8025 | E6025 | E4020 | E 3015 |

| Formato de processamento | 12000mm*2500mm | 10000mm*2500mm | 8000mm*2500mm | 6000mm*2500mm | 4000mm*2000mm | 3000mm*1500mm |

| Peso total | 23000kg | 18000kg | 14000kg | 10000kg | 6500kg | 4500kg |

| aceleração máxima | 1,5 G | |||||

| Máxima velocidade de posicionamento | 100M | |||||

| precisão de posicionamento | +0,02 mm | |||||

| Repetibilidade | +0,03 mm | |||||

| Adaptação de alimentação | 1.5-50KW | |||||

A escolha confiável para reduzir custos com operação fácil

Cobrem uma pequena área (19m2) para a alta utilidade de espaço

Adotar oco de máquinas-ferramenta, mais espessada ferramenta de bits e de grafeno/vermelho cobre, como prevenção de incêndio

Permitir livre de fumaça de corte devido inteligente espiral negativa-pressão do sistema de remoção de pó

Paralelas de alta velocidade da plataforma de intercâmbio de design, simultâneas de câmbio de duas mesas de trabalho, estável e de confiança, modo de transmissão, menor do horário do exchange.

Facilidade de transporte, reduzindo posteriormente os custos de manutenção.

Mantenha a máquina ferramenta indeformable e ininterrupta, a alta temperatura, mesmo após longo tempo de uso, pois de passar por 7 padrão de processos de 600° alta de recozimento

Com peso leve, de baixa inércia e excelente desempenho dinâmico, o feixe pode trazer de alta precisão, sem carga velocidade e eficiência de trabalho

Usamos componentes eletrônicos integrados e precisão do trilho de guia e racks (fósforo de 100%) para ativar a aceleração alta (1,2 G) e precisão de posicionamento (±0,05 mm).

Nós empregamos inteligentes baseados em barramento de sistema do CNC equipados com 21,5 polegadas tela de toque. É de fácil instalação e de depuração, com rápida e de rápida transmissão de dados, baixa taxa de falhas e de fácil manutenção.

Pequeno no tamanho e luz no peso, com todos os óptica e de água-de refrigeração design

Como um dos modelos clássicos, a Uma série de fibra máquina de corte a laser é usada principalmente para materiais metálicos, como aço inoxidável, aço carbono, chapas galvanizadas, latão, alumínio, e várias placas de liga leve

A série HWlEiC E oferece alta relação custo-benefício e elevado desempenho para diversos setores que buscam atualizar métodos de processamento de metais e aumentar a competitividade.

Por favor, preencha o formulário abaixo para solicitar um orçamento,catálogo,ou consulta técnica.A nossa equipa terá de volta para você dentro de 24 horas.

Nós responderemos dentro de 24 horas. Se for caso urgente, por favor, adicione o WhatsApp/WeChat: +86 15589913375. Ou ligue para +86 15589913375 diretamente.

*Nós respeitamos a sua confidencialidade e todas as informações estão protegidas.

Só usaremos suas informações para responder a sua pergunta e nunca envia e-mails não solicitados ou mensagens promocionais.

Ultimate dinâmica e eficiência

A durabilidade e a confiabilidade

Atualizado precisão e exatidão

Inteligente e facilidade de uso

Segurança & saudável

Versátil automação