Performance based on robustness and, above all, reliability.

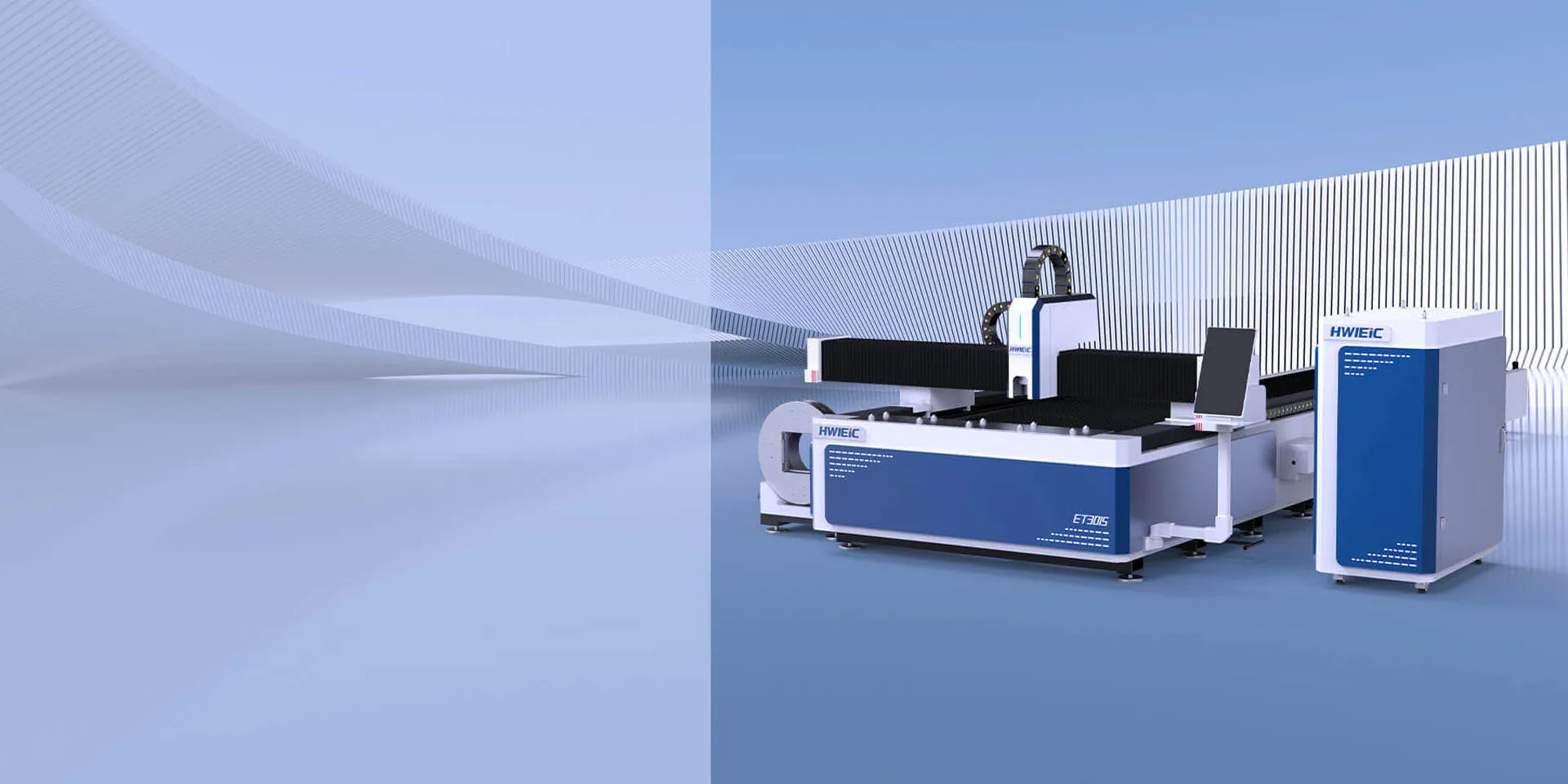

The ET series can quickly cut sheet metal and tubing, mostly used in the fitness equipment and furniture industries.

Open Type Sheet and Tube Combo - Features & Configuration

It can cut both sheet and tube. With it, you will take more cutting demands easy, save 50%+ space and halve your costs of purchase at least, gaining more advantages over peers while exploring new markets and customers.

Equipped With Top-Level Core Components

Features high-end CNC system, laser generator, and cutting head from leading brands—ensuring fast data response, stable interconnectivity, and low maintenance cost.

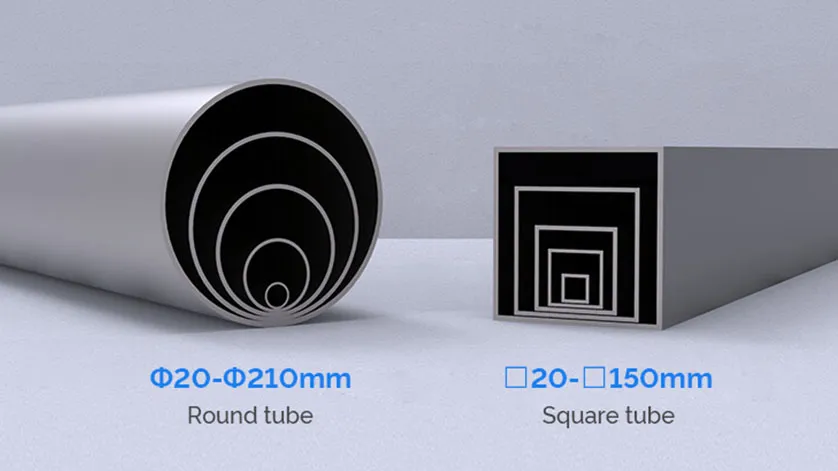

Cut tubes with short tailing

Its pneumatic chuck is self-centering and can clamp tubes of different shape, size and weight firmly, with no slip. Tube waste will be minimized.

High efficiency to free from worry

Seamlessly switches between sheet and tube cutting, runs faster than traditional methods, and supports one operator managing multiple machines.

Compact & Open-Frame Structure

Open three-sided access allows easy front, back, and side loading/unloading, with clear workflow visibility and quicker response to emergencies.

Open Type Sheet and Tube Combo With Robust, Safe, Essential

Core Performance & Structural Advantages

-

Graphite bed minimizes thermal deformation for stable long-term cutting.

-

±0.05mm accuracy with rack-and-pinion guide system ensures smooth motion.

-

Zoning dust removal improves scrap disposal and environmental cleanliness.

-

±45° bevel cutting supports X/Y/V shapes to reduce post-processing.

-

Cuts 6–90mm stainless steel, 5–80mm carbon steel, 5–60mm aluminum, 5–30mm brass.

-

CNC interface is user-friendly with visual guidance and multifunctional controls.

-

±3 arcmin transmission precision ensures stable and repeatable motion.

-

Safety curtains and emergency sensors protect both operator and machine.

-

Bed undergoes 7 heat treatments to resist long-term high-temp deformation.

-

Smart piercing tech prevents overburning and improves cut quality.

-

Handles 32000×5000mm full-size sheets without welding or segmentation.

-

Dual nitrogen gas setup ensures high-quality stainless steel cutting.

Flexibility and efficiency

Ensure safety, maximize material usage, and streamline operations for superior productivity and cost savings.

Why hwieic ?

- Ultimate dynamics and efficiency

- Durability and reliability

- Upgraded precision and accuracy

- Intelligent & ease of use

- Safety & healthy

- Versatile automation

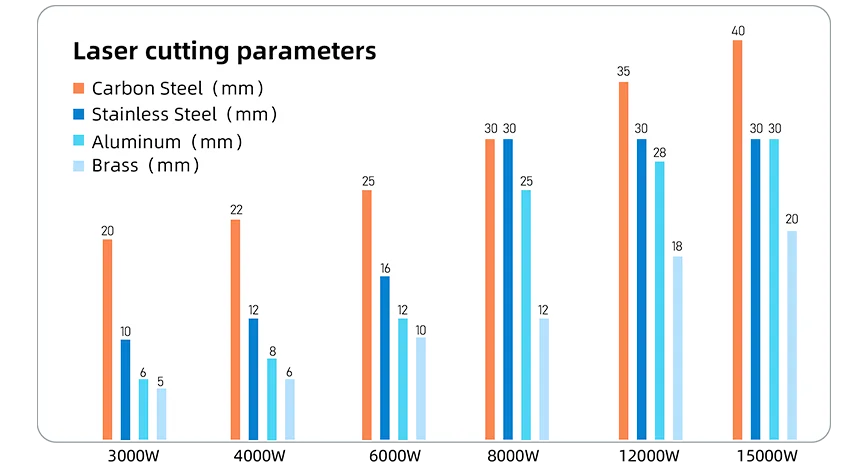

Product Performance

ET series fiber laser cutting machine cutting parameter charts show the normal and extreme cutting performance of various materials and thicknesses at different power levels.

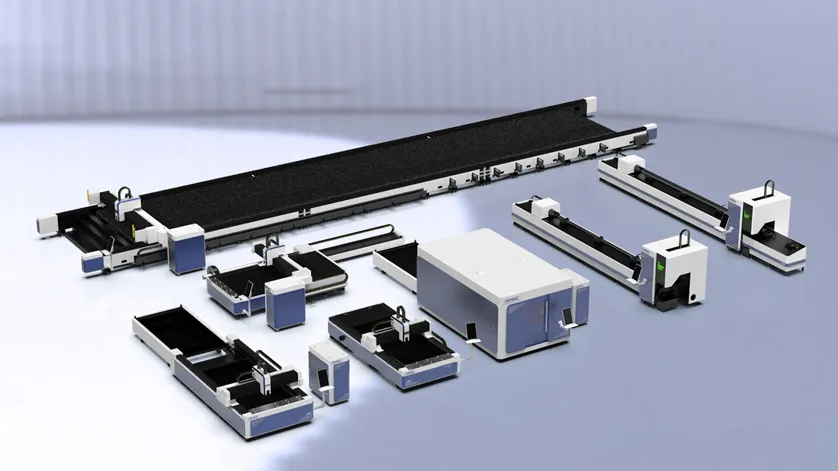

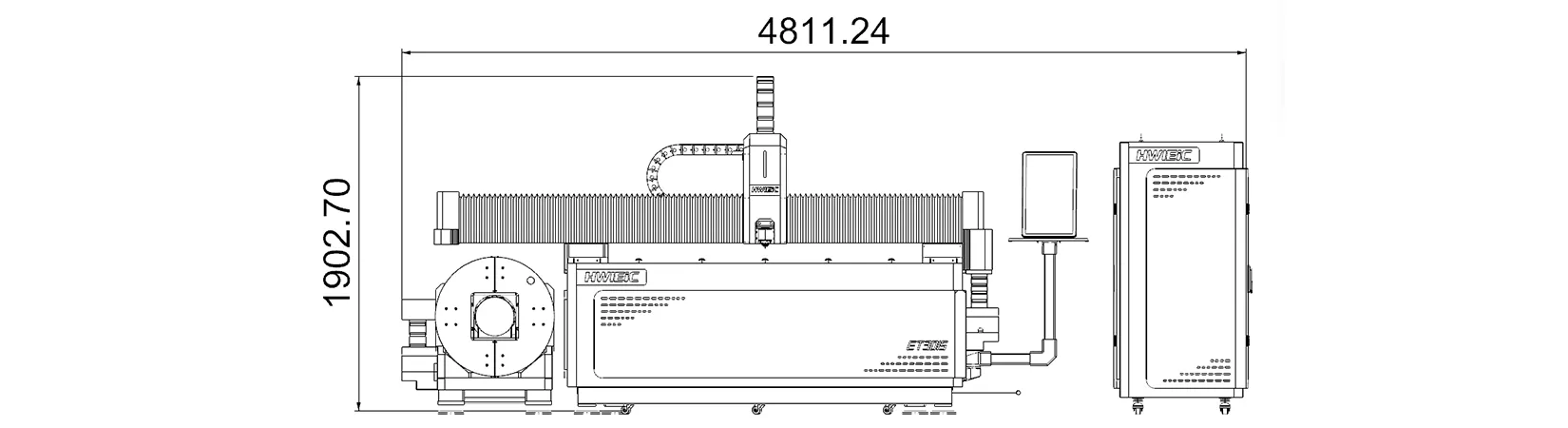

| MODEL | ET8025 | ET6025 | ET4020 | ET3015 | |

| Processing format | 8000mm*2500mm | 6000mm*2500mm | 4000mm*2000mm | 3000mm*1500mm | |

| Tube size range | Round tube Φ20-Φ210mm Square tube □20 – □150mm |

||||

| Electric chuck maximum load | 200kg | ||||

| Requirements for tubes | 0.8mm-10mm tube wall thickness | ||||

| Max. length of tube | 6000mm | ||||

Simply Efficien

ET series fiber laser cutting machine cutting parameter charts show the normal and extreme cutting performance of various materials and thicknesses at different power levels.

- Lightning-fast piercing

- Disc centering

- One-key fly cutting

Cost-efficiency

ET series reduces the need for multiple machines, offering both sheet and tube cutting capabilities in one unit.

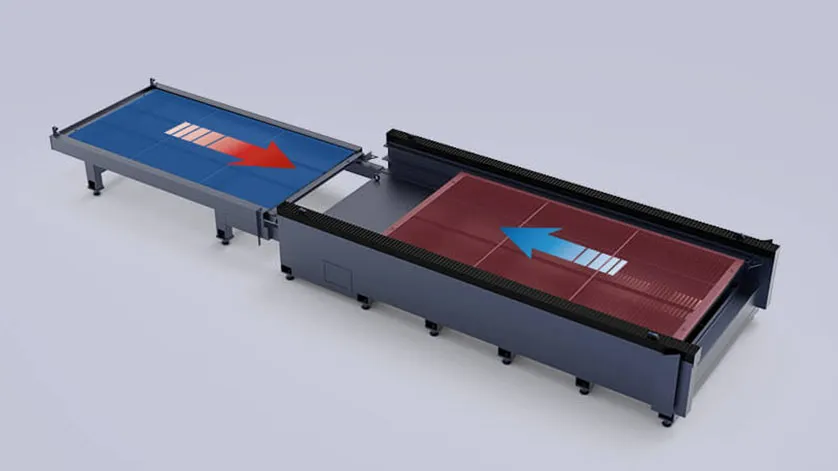

Users are allowed to switch between sheet cutting and tube cutting at will. It works dozens of times faster than the tradition.

One worker may control multiple machines to save labor force and raise work efficiency

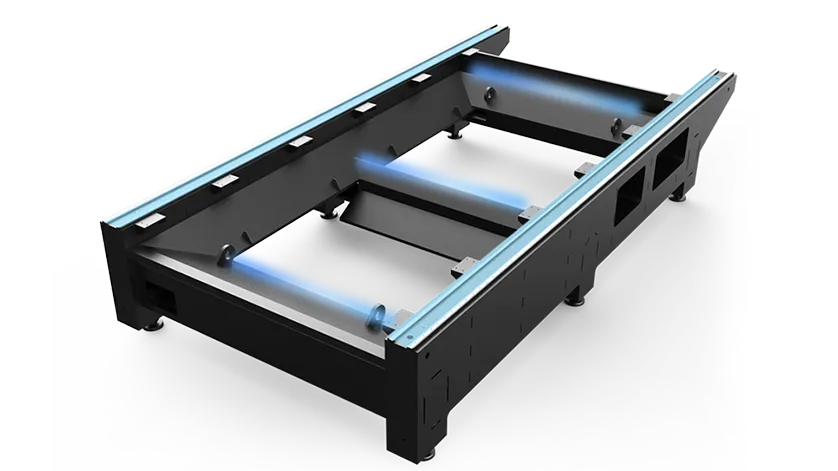

Parallel Switching Platform

It makes use of a parallel switching platform as well as a bilateral drive matching sprocket chain. Its characteristics include stability, good rigidity, and high speed.

Pipe Size

Supports round tubes Φ20–210 mm and square tubes 20×20–150×150 mm.

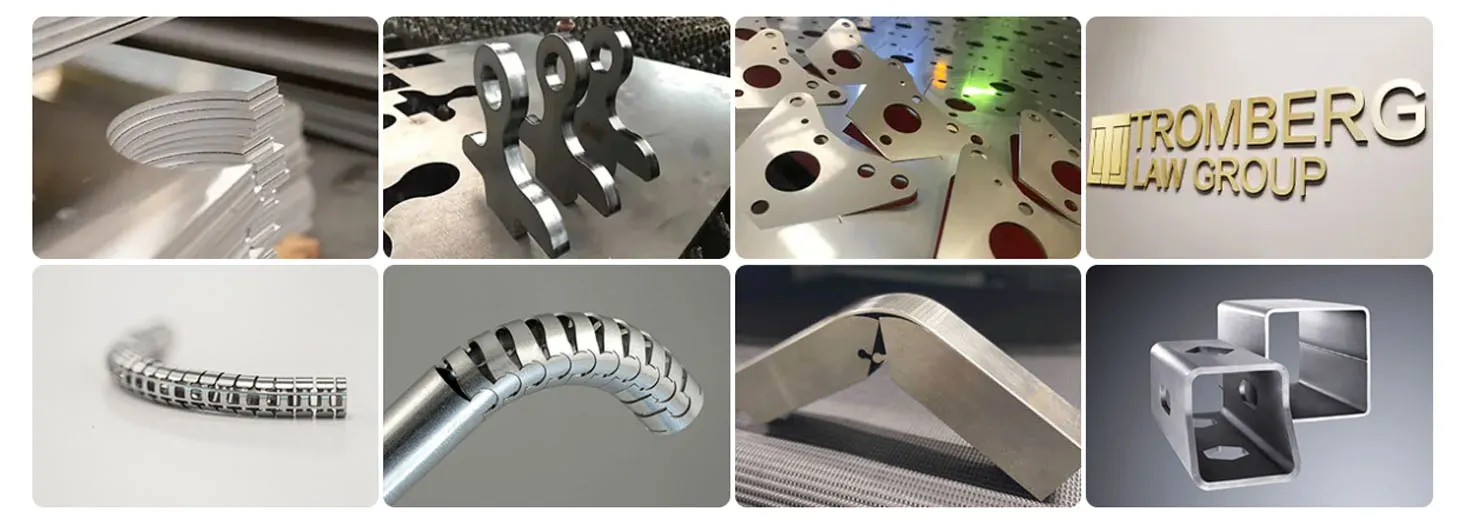

Deal with carbon, stainless steel, AL alloy, brass, galvanized sheet, silicon steel sheet, electrolytic sheet, titanium and manganese alloy

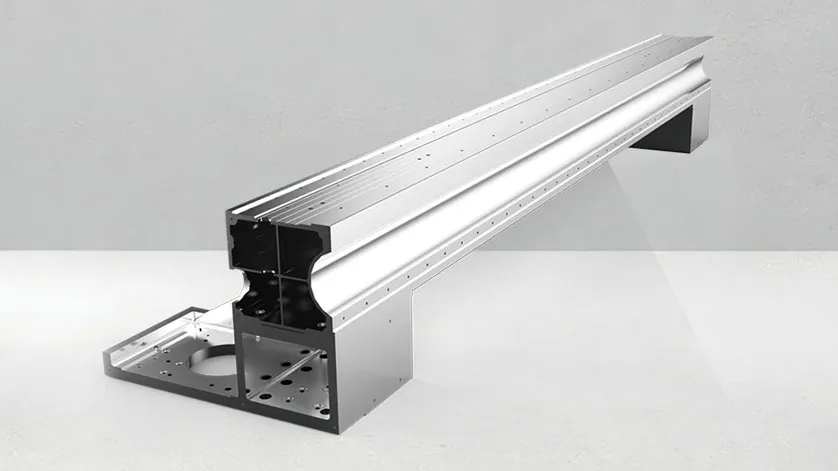

Aerospace-Grade Aluminum Alloy Crossbeam

Lightweight, low inertia, and excellent dynamic performance. Maximum no-load speed and acceleration reach 100 m/min and 1G respectively.

Robust structure and long service life

* The semi-hollow machine tool features a non-continuous internal design, effectively blocking heat transfer and ensuring that cutting accuracy is not affected.

* After undergoing 7 standard processes including high-temperature annealing and aging treatment, the machine tool will remain unchanged and undamaged even after prolonged high-temperature use.

Control System

This professional CNC system is internally installed with many functions, so as to lower failure rate and allow for easy use & maintenance.

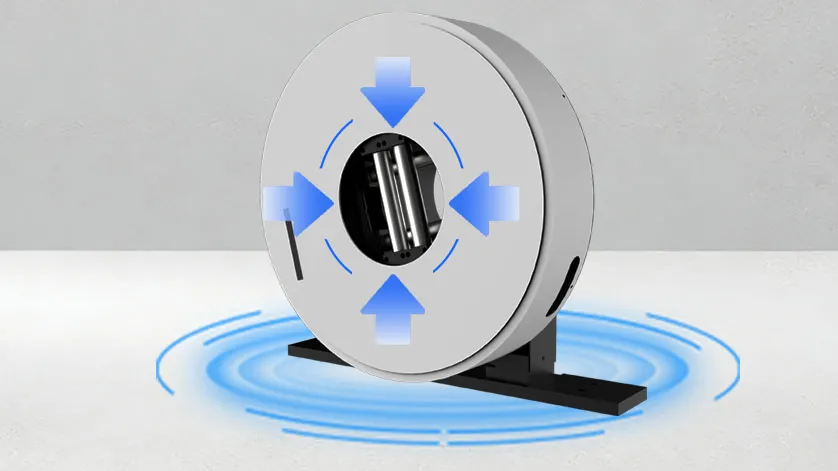

Auto-Focusing Laser Head

Auto-focusing reduces human intervention; auto-focusing range -12~+10mm; focusing accuracy 0.05mm; collimation with added protective lens effectively protects the collimating lens

Cut tubes with short tailing

Its pneumatic chuck is self-centering and can clamp tubes of different shape, size and weight firmly, with no slip. Tube waste will be minimized.

High Quality Results In All Sheet Thickness

As one of the classic models, the ET series fiber laser cutting machine is mainly used for metal materials such as stainless steel, carbon steel, galvanized sheet, brass, aluminum, and various alloy plates

Customer Visit

The HWlEiC Tseries provides cost-efficiency and high performance for various industries looking to upgrade metal processing methods and improve competitiveness.

Request A Quote

Please fill out the form below to request a quote,catalog,or technical consultation.Our team will get back to you within 24 hours.

Get a Quote

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 ******,. Or call +86 ****** directly.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.

Products

POWER TOOLS

Ultimate dynamics and efficiency

Durability and reliability

Upgraded precision and accuracy

Intelligent & ease of use

Safety & healthy

Versatile automation