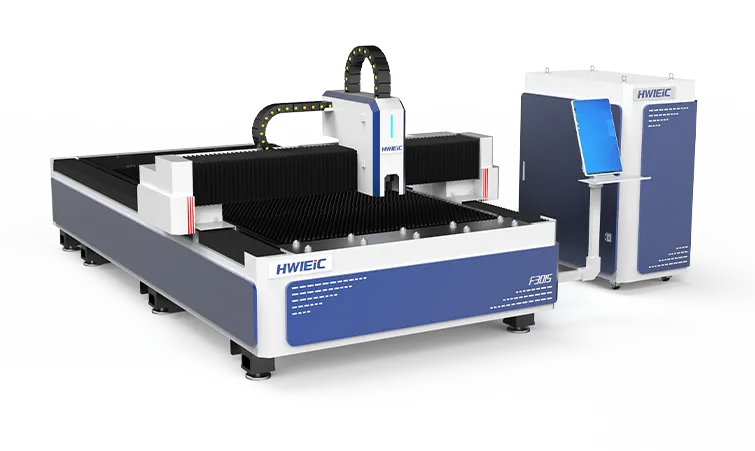

Série F

Flagship Product sheet fiber laser metal cutting machine

Superior Performance F Series Delivers Top-Notch Quality, Allowingfor Faster, Smoother, And More Precise Lasercutting. An ideal Choice To Meet Your Highstandards.

A deformação livre de corte de aço inoxidável, aço carbono, chapa de cobre, chapa de alumínio, etc. Velocidade de corte rápido, de alta precisão, corte contínuo por um longo tempo. Perfuração, abertura de canais, corte de gráficos, etc. Feixe de boa qualidade, sem rebarbas, sem escória, sem a borda preta, sem a necessidade de processamento secundário Mais estreito corte de costura, no mínimo, zona afetada pelo calor, local mínimo deformação da peça.

Depois de técnicas e funcionais atualizações, este modelo possui rico de funções e desempenho estável, fornecendo aos clientes com rapidez e alta qualidade de corte de média-folhas finas.

Desempenho Superior

Depois de técnicas e funcionais atualizações, este modelo possui rico de funções e desempenho estável, fornecendo aos clientes com rapidez e alta qualidade de corte de média-folhas finas.

A alta potência, seu corte de seção é lisa, sem rebarbas ou o cumprimento de escória. Basicamente, não há necessidade de secundário de polimento.

Mantenha a máquina ferramenta indeformable e ininterrupta, a alta temperatura, mesmo após longo tempo de uso, pois de passar por 7 padrão de processos de 600° alta de recozimento

Um 40HQ pode conter 8 conjuntos de 3015F, que fornece uma nova opção para o volume de encomenda de clientes e nitidamente reduz custos de envio.

Design compacto integra armário de poder, sistema de controle, laser e refrigerador em um 12m2 pegada.

Abrir-estrutura de corpo oferece uma visibilidade completa e fácil de carregar a partir de três lados.

Integrado armário elétrico separado com forte/fraco da corrente, reduz a interferência e aumenta o tempo de vida.

Reforçado e soldado cama sofre alívio do stress e do envelhecimento, tratamento para duração de rigidez.

Modular firebrick protegido ferramenta de bits são fáceis de substituir e mais seguro durante o corte.

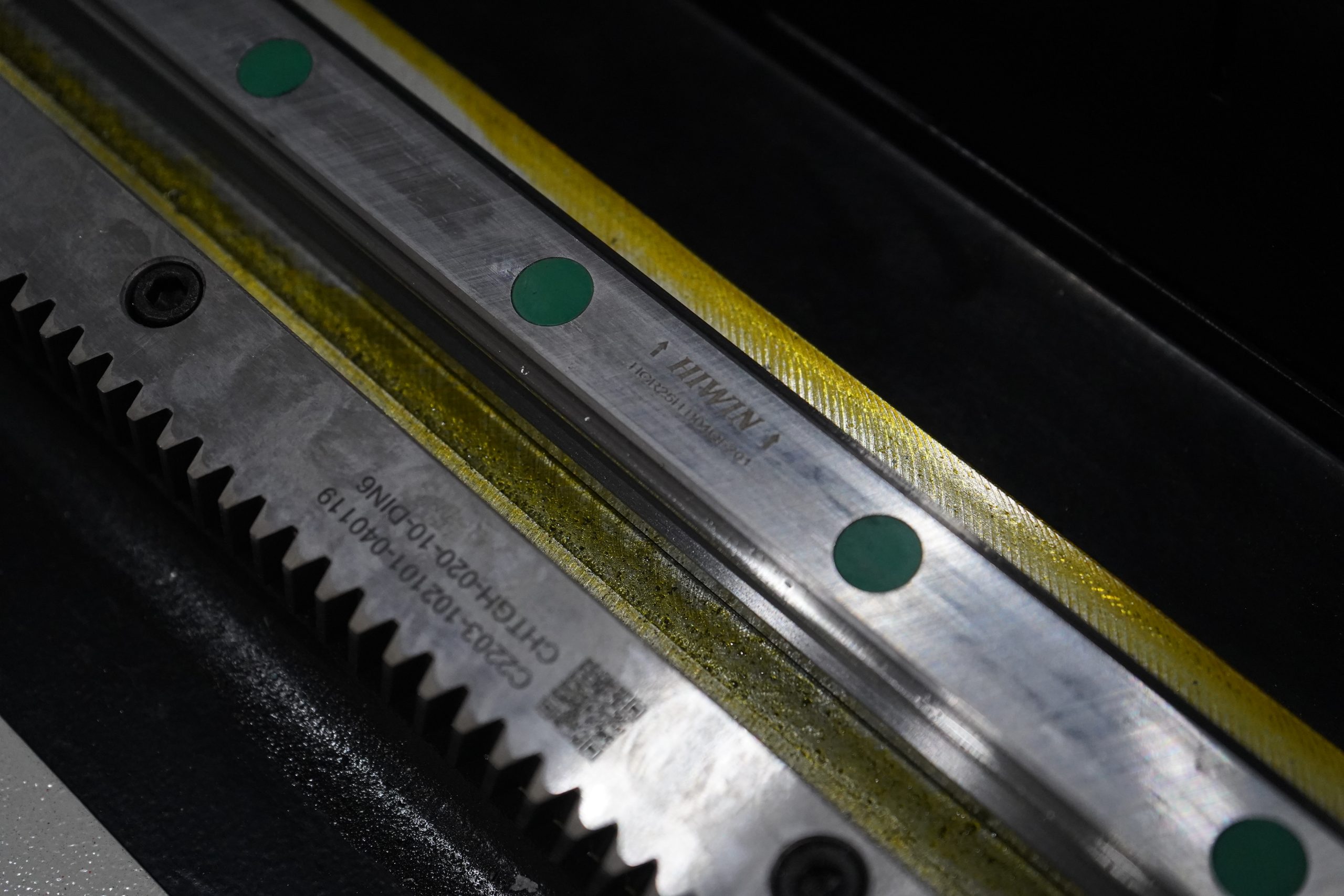

Alta resistência em liga de alumínio feixe garante um movimento mais rápido e precisão de corte.

Dupla de condutas de ventilação e aspiração-o golpe de design criar fumaça-oficinas gratuitas.

Inteligente ônibus CNC com 21.5" touchscreen oferece rápida e estável de dados e de fácil instalação.

Um clique em disco de centralização melhora o posicionamento da peça e a precisão do corte.

Multi-estágio piercing adapta-se em tempo real para diferentes folha de espessuras.

Smart evitar obstáculo impede colisões e protege as peças de trabalho.

Proporciona limpeza, sem rebarbas, polonês livre de cortes, mesmo com alto poder de espessura da folha de postos de trabalho.

Um 40HQ se encaixa 8 conjuntos de 3015F, corte a massa custos de envio drasticamente.

Abrir-estilo de design oferece suporte eficiente de manuseio de material e de melhor produção de visibilidade.

Concebidos para a precisão, a velocidade e o mínimo de pós-processamento em média-fina folha de corte.

Seu design minimalista combina o seu corpo principal, armário elétrico, sistema de controle, compressor de ar, gerador de laser, e do refrigerador de água em um, de modo a reduzir o espaço de custos e melhorar o workshop de utilização.

Depois de técnicas e funcionais atualizações, este modelo possui rico de funções e desempenho estável, fornecendo aos clientes com rapidez e alta qualidade de corte de média-folhas finas.

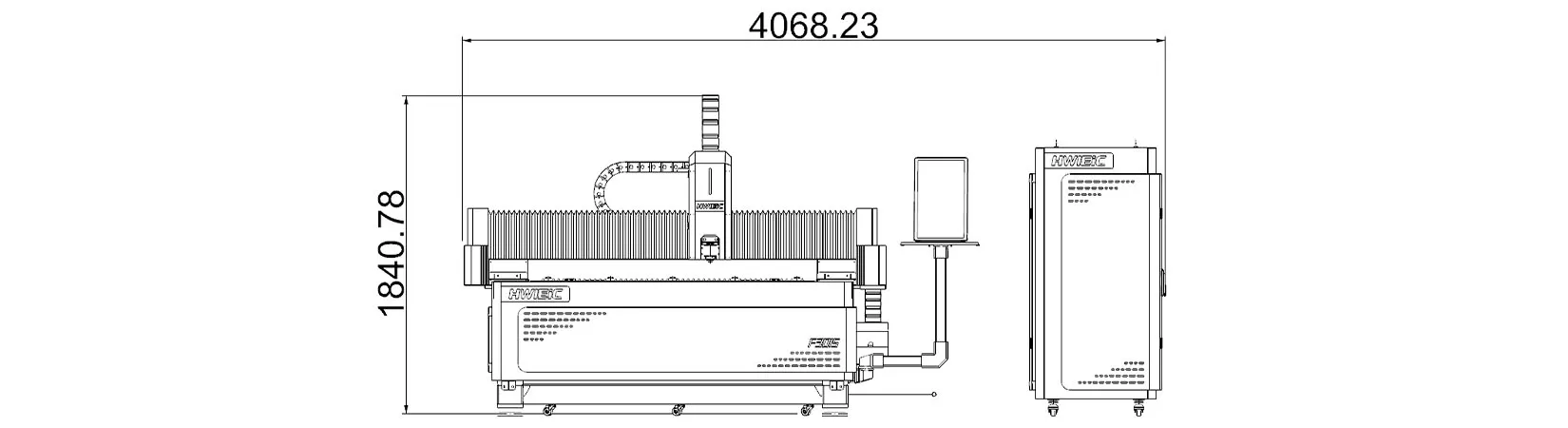

| MODELO | F6025 | F6015 | F4020 | F3015 |

| Área de trabalho | 6000mm*2500mm | 6000mm*1500mm | 4000mm*2000mm | 3000mm*1500mm |

| Laser potência de saída | 1.5-50KW | |||

| Precisão de posicionamento | ±0,01 mm/m | |||

| Precisão de reposicionamento | ±0,01 mm | |||

| Max. ligação de velocidade | 200m/min | |||

A escolha confiável para reduzir custos com operação fácil

Seu design minimalista combina o seu corpo principal, armário elétrico, sistema de controle, compressor de ar, gerador de laser, e do refrigerador de água em um, de modo a reduzir o espaço de custos e melhorar o workshop de utilização.

* Abrir-estrutura de estilo sem tampa superior, dando uma visão abrangente de todo o processo de corte. Existem olho rodas da esquerda e da frente da máquina-ferramenta cama, para fazer o carregamento e descarga de esquerda, direita e traseira do lado mais fácil.

* Compacto na estrutura com plataforma única e laser embutido gerador, que ocupa um espaço pequeno (apenas 12m2).

* Integrado de distribuição de energia do gabinete, com a separação fortes e fracos atual para reduzir a interferência elétrica e melhorar a estabilidade de trabalho e tempo de vida.

Customizable Laser Power, Cutting Heads, Controls & Intelligent Auxiliaries

Com peso leve, de baixa inércia e excelente desempenho dinâmico, o feixe pode trazer de alta precisão, sem carga velocidade e eficiência de trabalho.

Nós empregamos inteligentes baseados em barramento de sistema do CNC equipados com 21,5 polegadas tela de toque. É de fácil instalação e de depuração, com rápida e de rápida transmissão de dados, baixa taxa de falhas e de fácil manutenção.

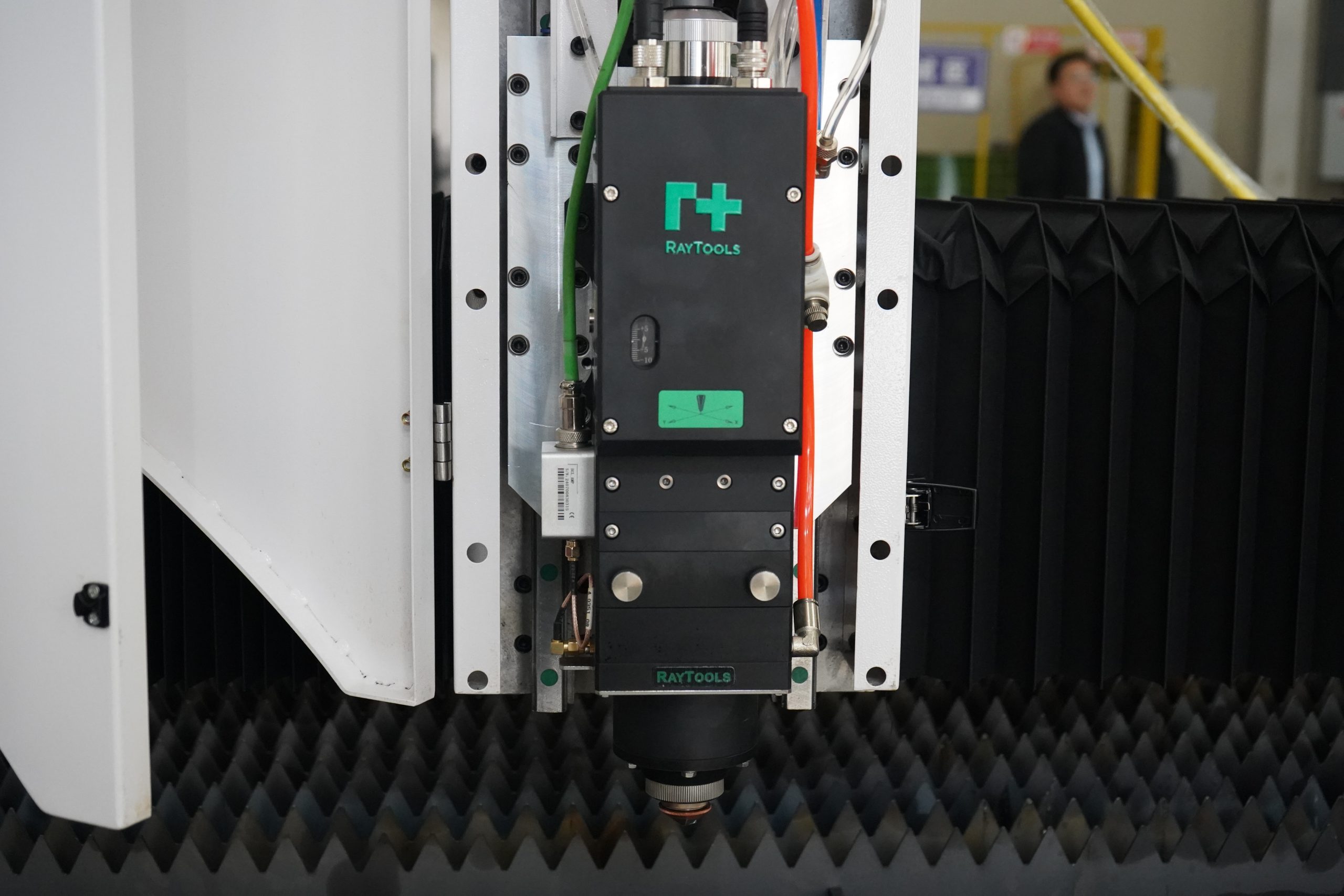

Pequeno no tamanho e luz no peso, com todos os óptica e de água-de refrigeração design

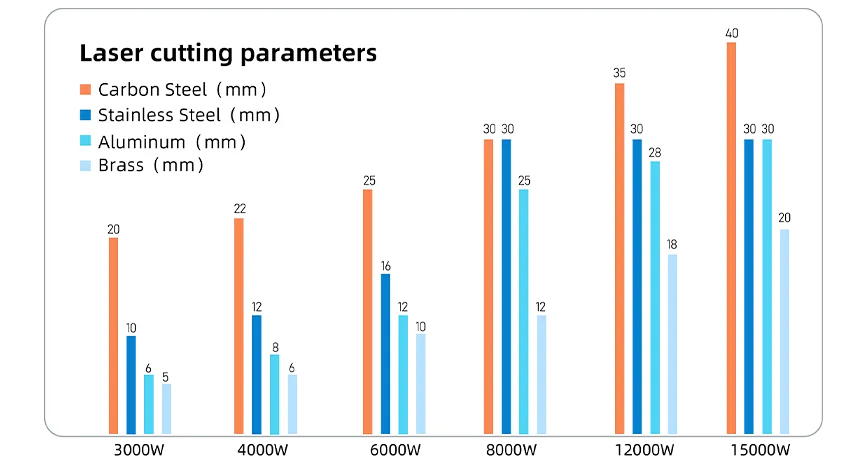

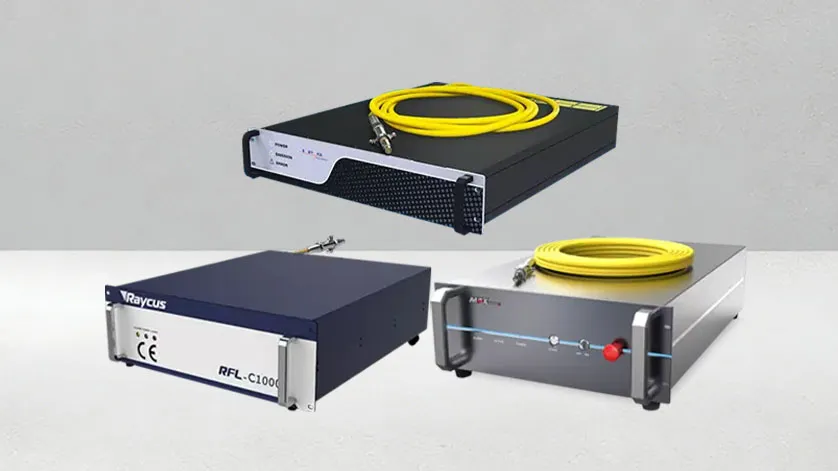

Multiple types of high-quality laser sources available with full power coverage from 1500W to 50000W, tailor-made processing solutions on demand

Alta estabilidade fonte de laser com uniforme de produção de energia, equilibrando eficiência de corte e precisão de processamento

Completa gama de potência adaptados para o processamento industrial de materiais diversos, proporcionando um ambiente altamente confiável núcleo de poder para diferentes cenários

Como um dos modelos clássicos, a Uma série de fibra máquina de corte a laser é usada principalmente para materiais metálicos, como aço inoxidável, aço carbono, chapas galvanizadas, latão, alumínio, e várias placas de liga leve

O HWlEiC série F oferece eficiência de custo e de alto desempenho para várias indústrias em busca de atualização de metal métodos de processamento e melhorar a competitividade.

Por favor, preencha o formulário abaixo para solicitar um orçamento,catálogo,ou consulta técnica.A nossa equipa terá de volta para você dentro de 24 horas.

Nós responderemos dentro de 24 horas. Se for caso urgente, por favor, adicione o WhatsApp/WeChat: +86 15589913375. Ou ligue para +86 15589913375 diretamente.

*Nós respeitamos a sua confidencialidade e todas as informações estão protegidas.

Só usaremos suas informações para responder a sua pergunta e nunca envia e-mails não solicitados ou mensagens promocionais.

Ultimate dinâmica e eficiência

A durabilidade e a confiabilidade

Atualizado precisão e exatidão

Inteligente e facilidade de uso

Segurança & saudável

Versátil automação