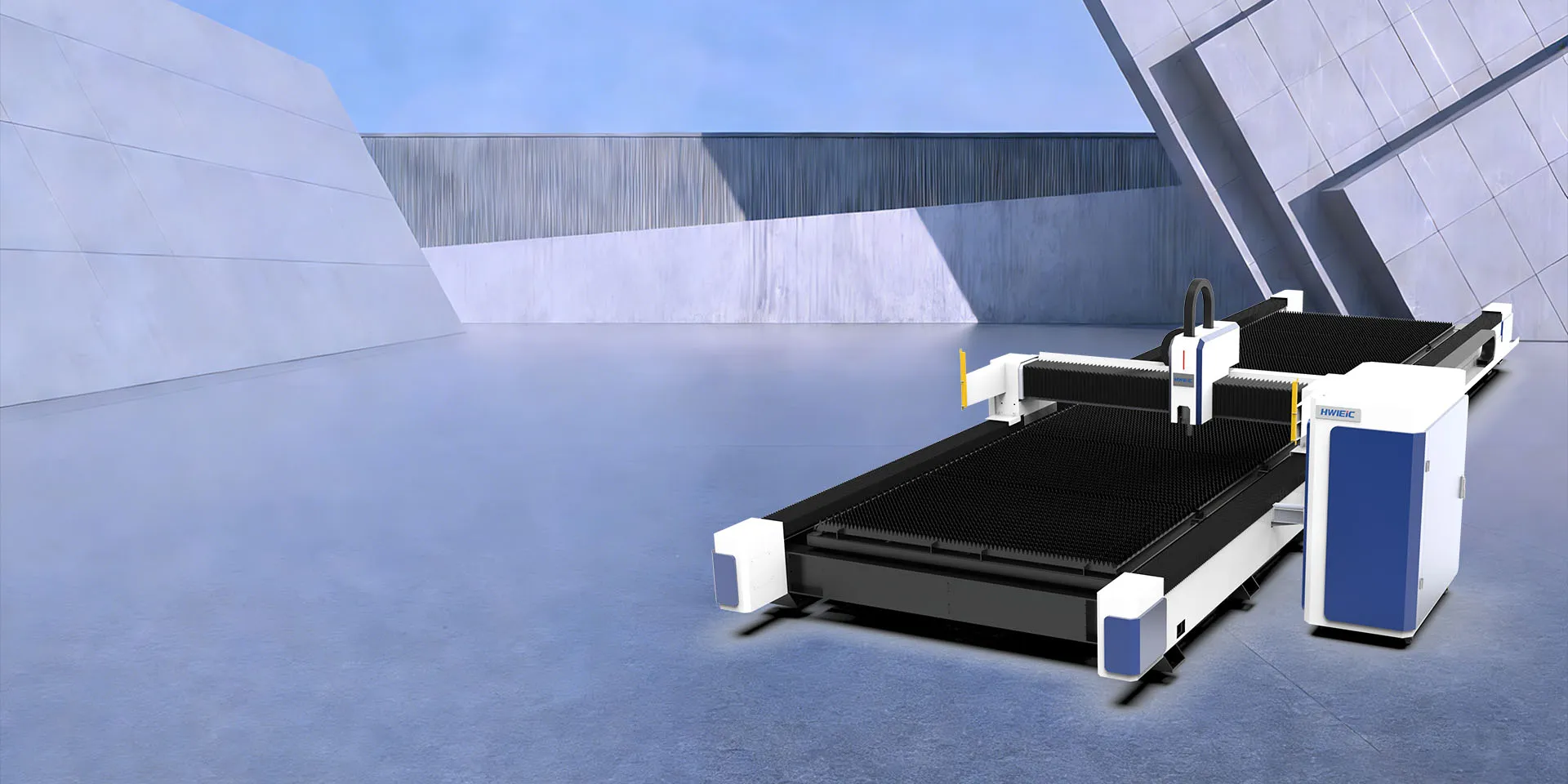

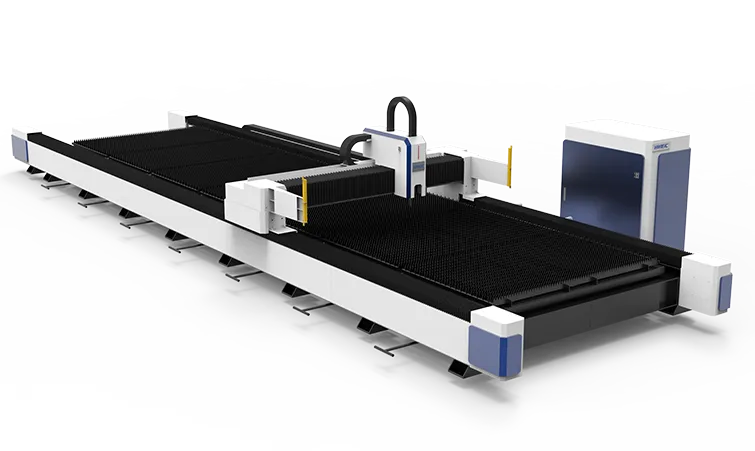

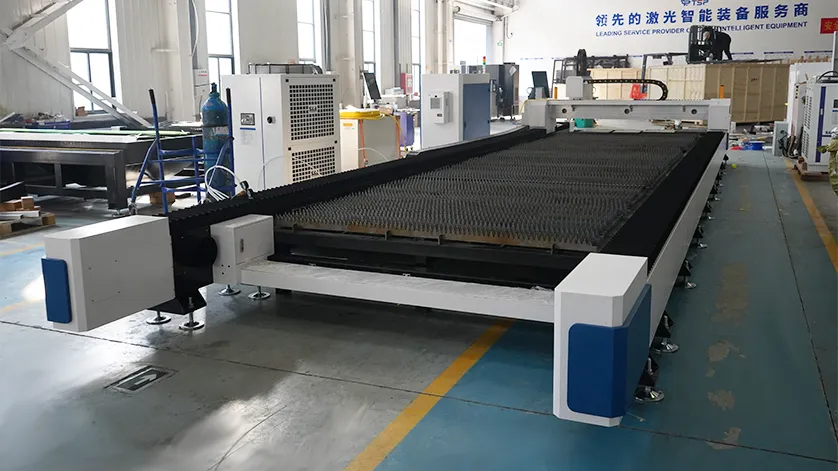

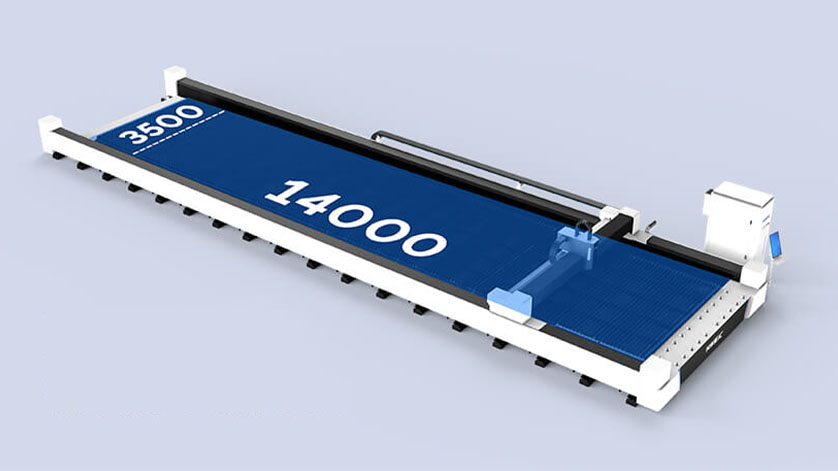

Seri G

Pemotong Logam Laser Format Sangat Besar

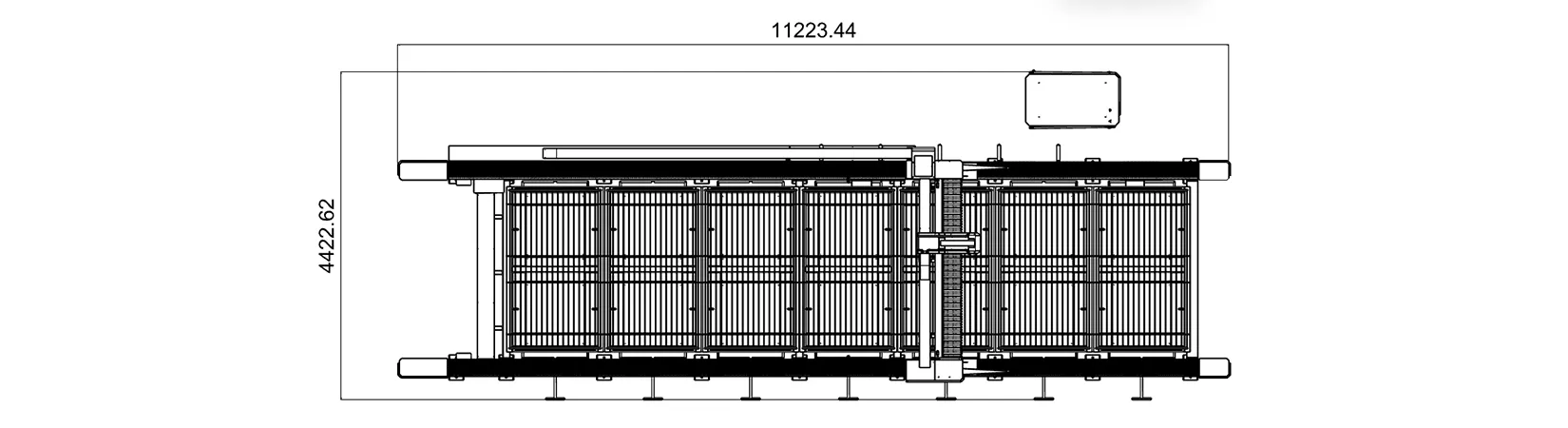

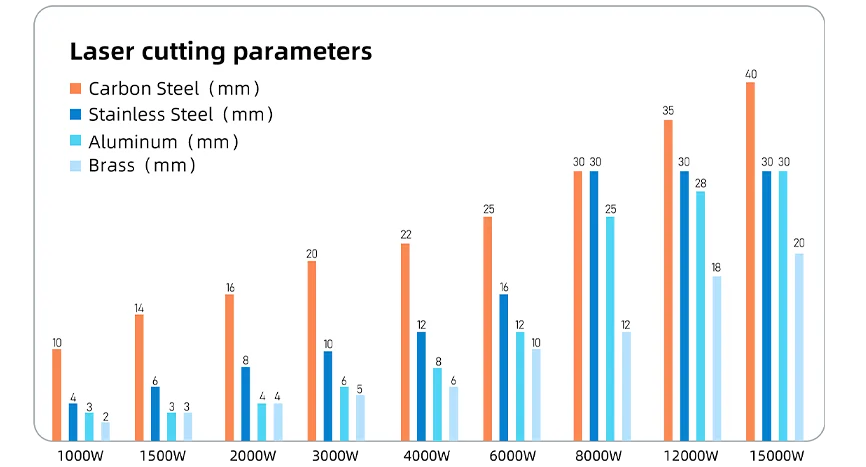

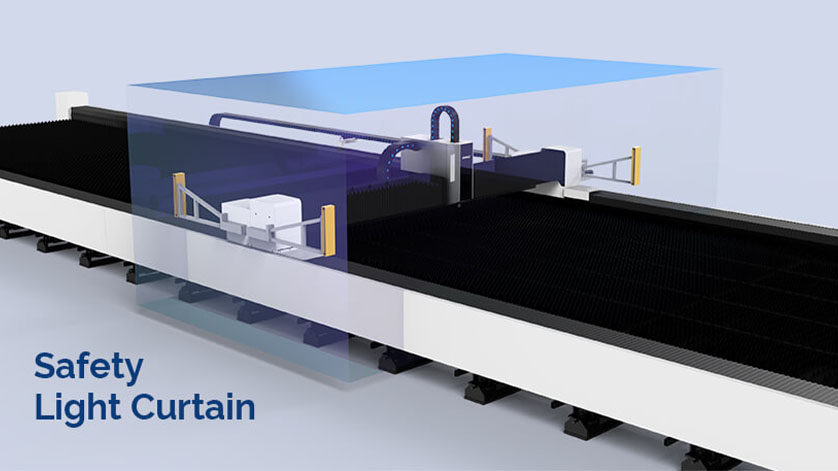

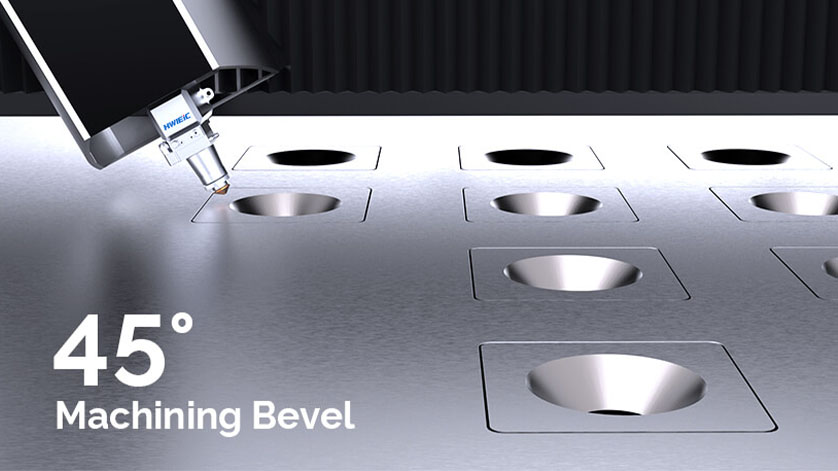

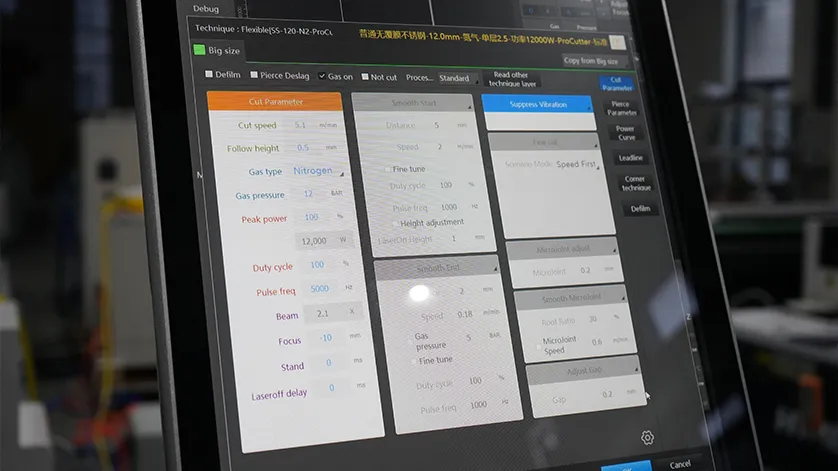

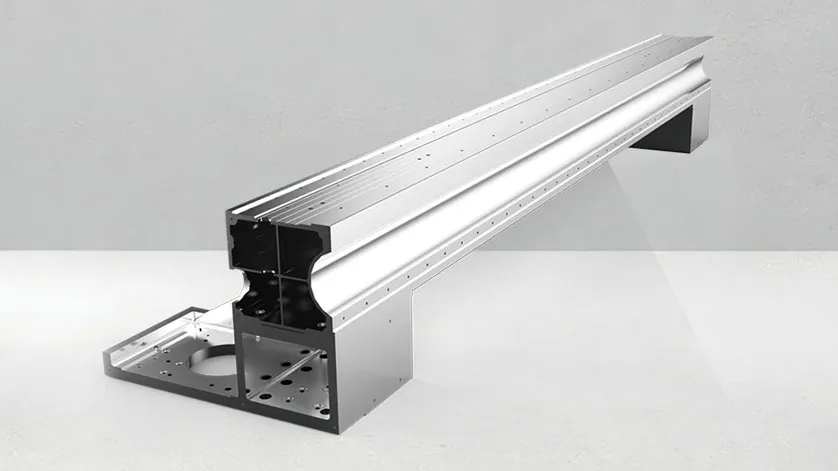

This Super-Sized Machine May Be Customized As Needed In Terms Of Working Area Because Of Its Modular Body. For Some Extra-Large Workpieces, It Is Easy To Cut And Transfer. Such UltraHigh-Power Model Fits To Cut Long (26000mm) And Heavy Sheets As A Good Choice For Shipbuilding, Engineering And Construction Machinery, Etc.