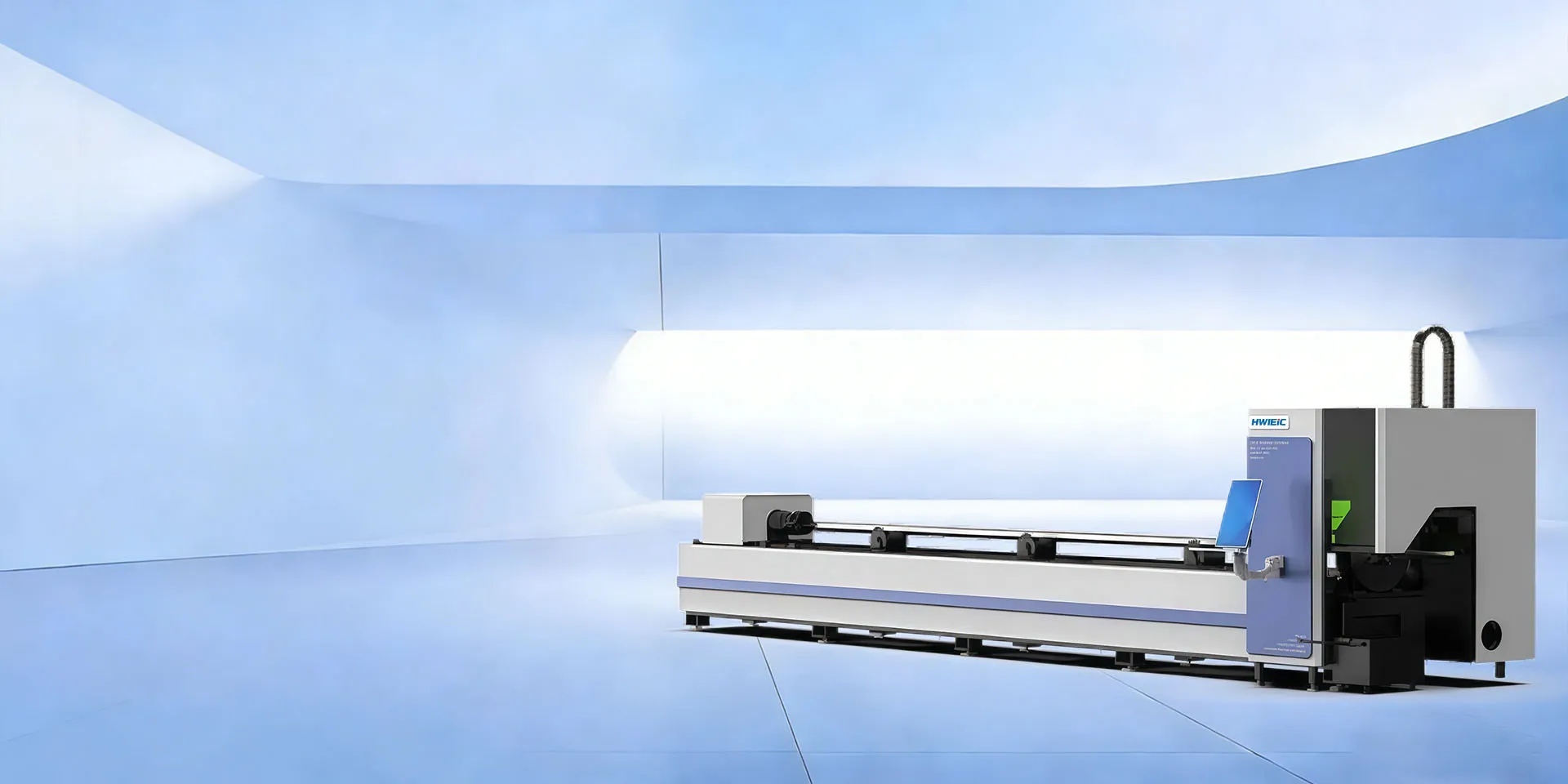

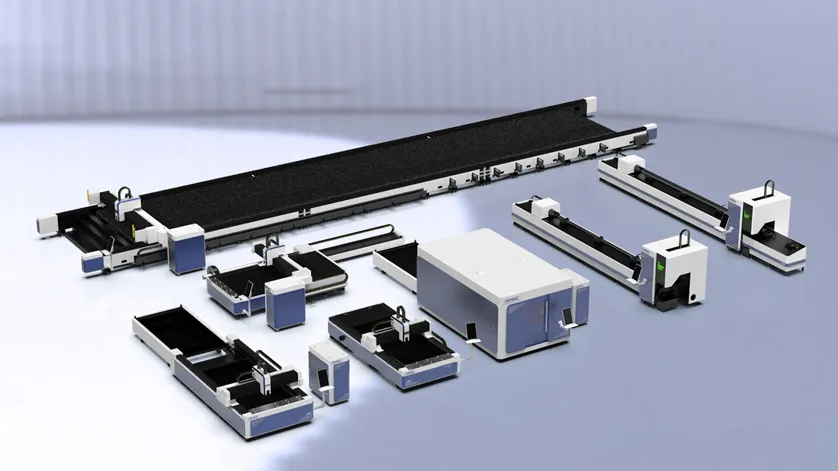

T 시리즈

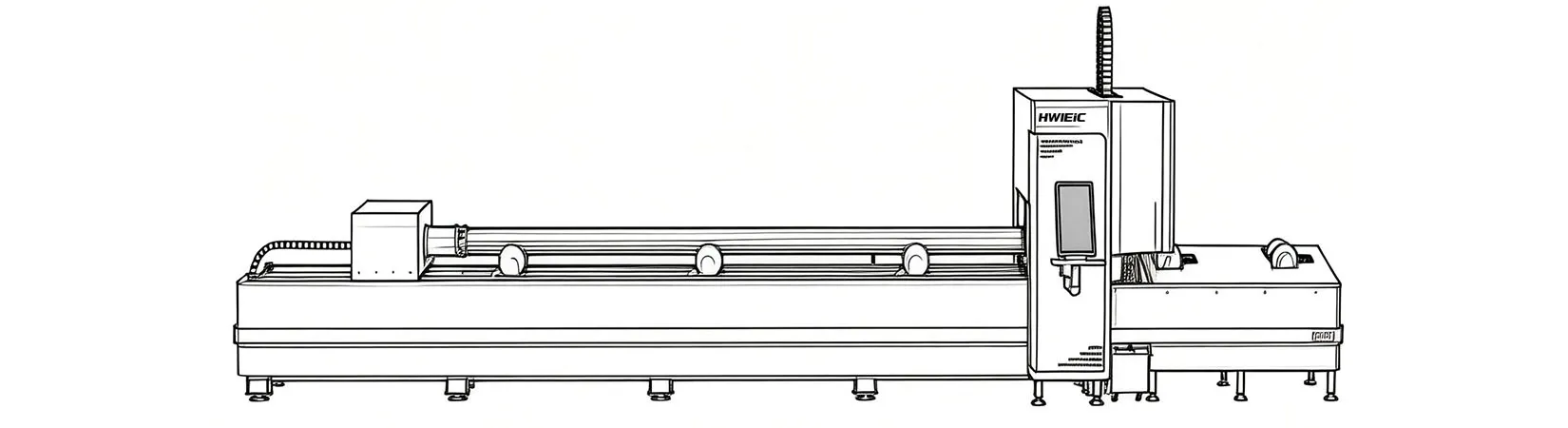

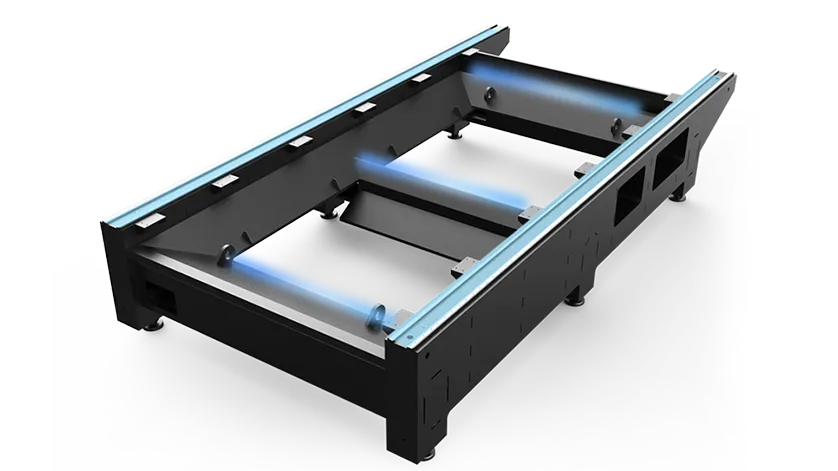

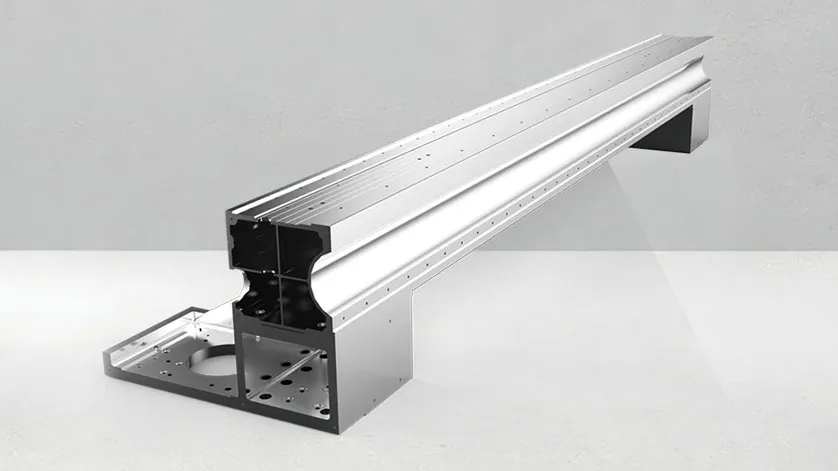

레이저 튜브 절단기를 가진 듀얼 척

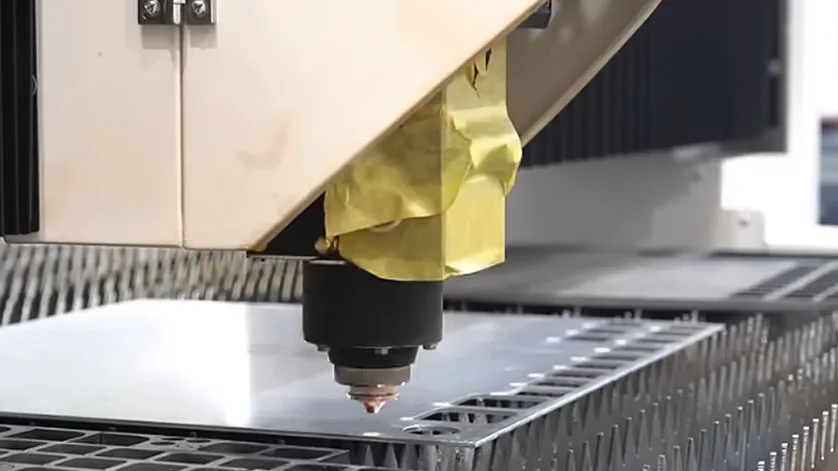

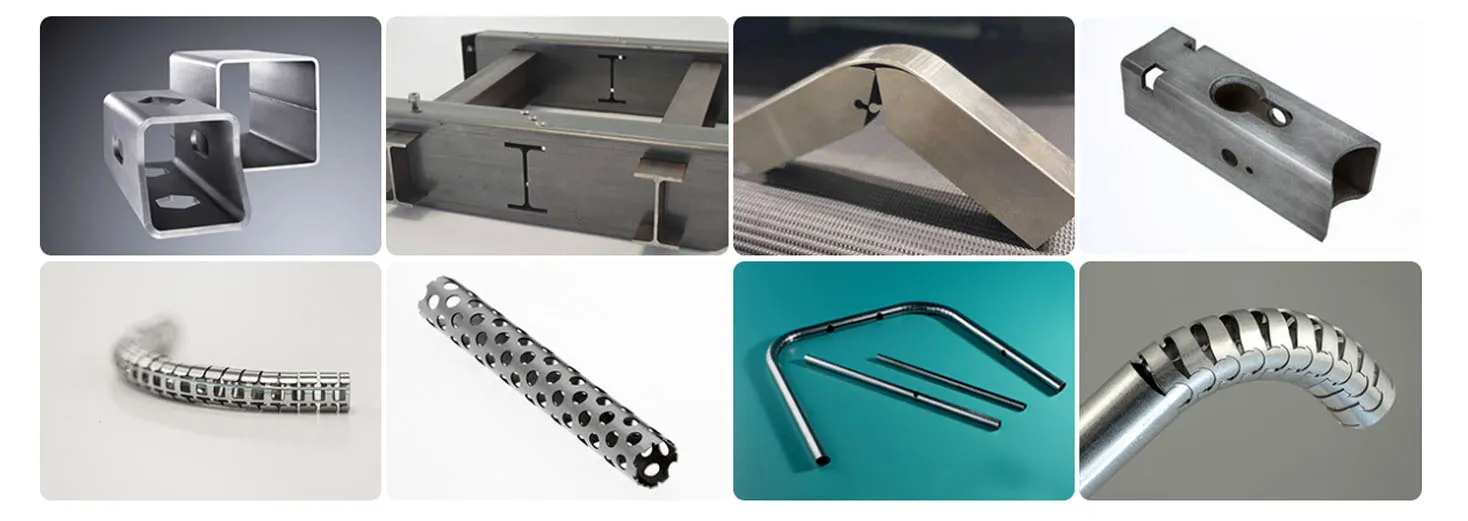

With Advanced Configurations, T Series Come Standard With Two Chucks To Cut Tubes With Ultra-Short Tailing. For Small Tube, There Is No Overburning Or Adhering Slag. As For Large Tube, The Cutting Is At Fast Speed. It Enjoys Fast Shipment And Delivery, And Is Widely Used In Rail Transit, Automobile Production, Construction Machinery, Agricultural And Forestry Machinery, Etc.