HJ 시리즈

소형 광섬유 레이저 용접 기계

This Is Our New Generation Of Laser Welding Machine. The Reason Why We Rate It As Cost Effective Is That It Combines Welding, Cutting And Cleaning Together At A Lower Price.

이 기계로 알려져 있는 최고의 소형 레이저 용접 기계를 위한 금속 제작,제공에 대한 정확하고 효율적인 용접 솔루션입니다.

핸드헬드 레이저 건은 지능형 컨트롤러를 통해 용접, 세척 및 절단 작업에 사용할 수 있으며, 조작이 간편하고 가공이 유연합니다. 또한 휴대가 쉽고 소형 설계로 비용이 낮으며 소모품이 필요 없습니다.

그것의 용접 속도는 곱,3~10 배 이상 빠른 속도를 자랑하는 전통

•정확하고,심미적인 용접을 위한 마이크로품 •최소한의 연마와 부드러운 레이저 시작/중지 •낮은 열 입력을 보장 강하고,깨끗한 용접

실 엉덩이 겹쳐,스티치,물고기 규모의 스터드,T-joint,내부,외부 용접,etc.

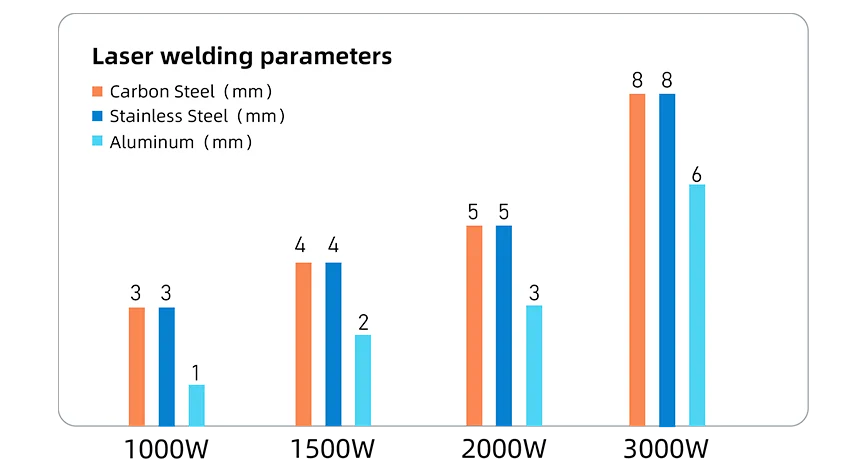

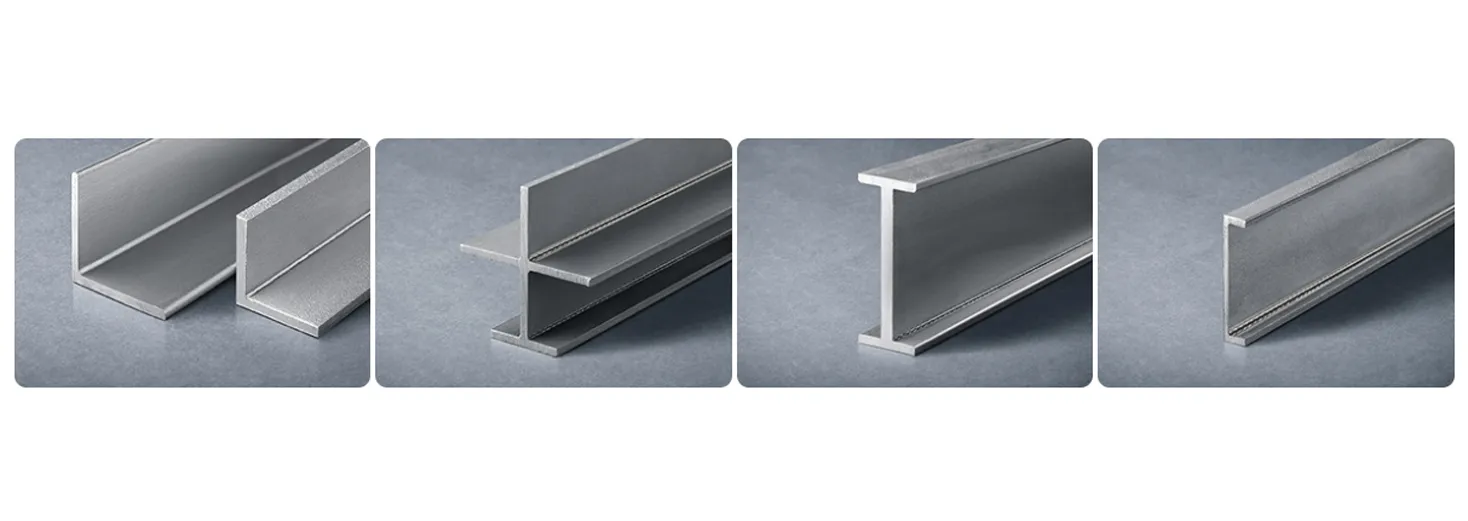

에 적용되는 탄소 강철,스테인리스 스틸,알루미늄 합금,직류 전기를 통한 시트,냉간압연 강판 및 강대,티타늄 합금,등등.

콤팩트한 소형 레이저 머리 수 있습 마이크로 용접 작은 부분에 높은 심 품질입니다.

점진적인 레이저 상승/하강 에서 용접 포인트 피 구덩이에 대한 필요성을 감소시키는,연삭.

낮은 열 입력 변형을 최소화 및 언더컷을 강 용접합니다.

정밀된 빔을 제공하는,부드럽고 깨끗하고 관절 최소화한다.

공기 냉각되는 레이저 시스템을 간소화 유지 관리와 필요한 물 냉각장치입니다.

고속 검류계 검색을 통한 정확한 용접 궤도.

통합 제어 및 레이저 원본 디자인을 감소 발자국 배선과 복잡합니다.

에 적합한 얇은 금속하고 복잡한 형상을 지원하고,다 각 용접입니다.

인체공학적 처리 및 가벼운 몸을 개선 통신수 편안하는 동안 긴 이동합니다.

지원 스폿 용접,솔기 용접,와 스티치한 용접 형태에 대한 유연합니다.

실시간 디스플레이 직관적으로 터치 스크린을 위한 빠른 설정 및 모니터링할 수 있습니다.

내장에서 안전 장치 및 경보기 연산자를 보호합니다.

선택 사항 증기 추출 시스템은 작업 영역을 깨끗하고 안전합니다.

에너지 효율적인 레이저 소스가 제공 긴 수명과 낮은 비용을 실행.

안정적인 전력 출력을 보장하는 일관된 용접 침투과 품질입니다.

와 호환되는 자동 업그레이드는 인라인 또는 로봇합니다.

도록 안전성 극대화하는 재질 사용 및 운영을 간소화하고 우수한 생산성 및 비용 절감 효과를 제공합니다.

정확히 제어 레이저 광선,빠른 작업속고 물 냉각 기계를 위해 일할 수 있는 시간이 오래 지속적으로. 그것은 FDA 및 세륨 증명서를 받습니다.

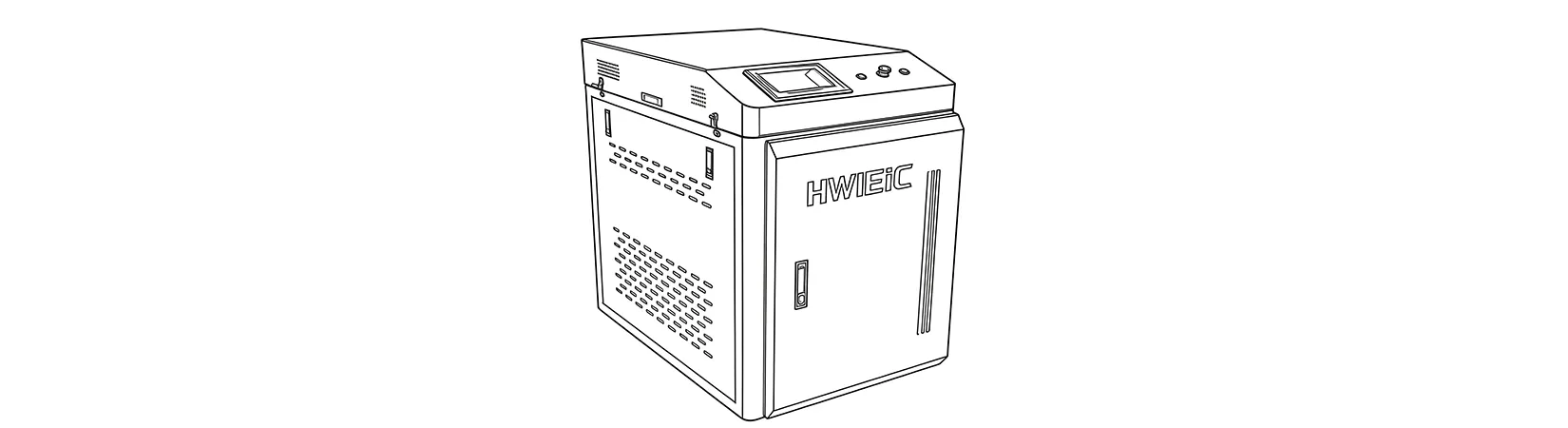

| 모델 | HJ-1000 | HJ-1500 | HJ-2000 | HJ-3000 |

| 레이저 전원 | 1000w | 1500w | 2000w | 3000w |

| 운영 모드 | 지속적인/변조 | |||

| 전원 요구사항 | 220V/50Hz/60Hz | 380V/50Hz/60Hz | ||

| 작동 온도 | 15-35℃ | |||

| 작동 습도 | <70%비응축 | |||

| 최대 용접 두께 | 0.5-2.5mm | 0.5-3.5mm | 0.5-4mm | 0.5-8mm |

| 용접 라인 요구사항 | ≤0.5mm | |||

| 최대 용접 속도 | 120mm/s | |||

| 기계 크기 | 1300*1200*800mm | |||

| 기계 무게 | 200kg | |||

신뢰할 수 있는 선택을 위한 더 낮은 비용으로 쉽게 조작

· 시트 메탈 구조를 최적화하여 컴팩트한 설계를 구현했으며, 전체 크기를 약 15% 줄였고 설치 면적은 0.7㎡ 미만입니다(와이어 피더 제외).

*에서는 디자인,물과 전기를 분리,싱글 채널 열 분산 및 1-1.5mm 두꺼운 금속 격판덮개는 사용 주체

*때문에 유니버설 캐스터,그것은 쉽게 이동에 대한 심지어 하나의 작업자가 그것을 만들 수 있습 중 하나에 의해 손으로

철사 먹이는 속도는 조정가능한에서 25~600cm/min 에서 지속적인 펄스 모드입니다. 그것의 최대 먹이는 와이어 직경에 도달 2mm. LCD 디스플레이,취할 수 있는 지능형 제어 철사 먹이는 속도입니다.

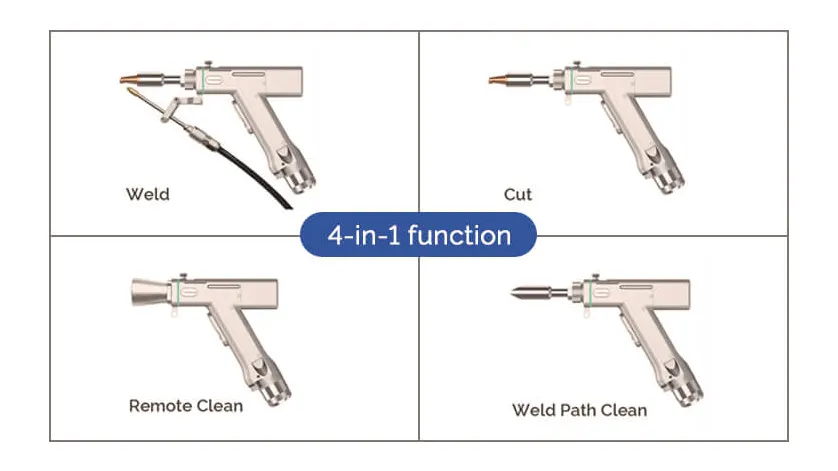

을 갖추고 있 4-in-1 레이저 용접 머리가 허용한 유연한 전환 사이에서 용접,절단,녹 제거하고 용접 이음매의 청소가 있습니다. 75 종류의 기술,사용자가 설정할 수 있습니다 매개변수에 의해 할 때 자신을 시도하려는 다른 효과.

*실행의 길이는 용접:0-6mm

*실행의 길이클리닝:0-120mm

*길이를 실행의 용접 이음매의 세척:0-8mm

우리가 충분히 생각하고 행동하고 사용 습관을 디자인하는 동안. 지금,추가적인 최적화를 만들어 작업을 만들기 위해 더 편리하고 쉽습니다.

*측 연결 옷걸이 보유는 용접 헤드(≤0.7kg)근로자의

*냉각 시스템이 효율적이고 안정적인 사용할 수 있습니의 출력 레이저 광속

*는 서비스 유형을 보호 렌즈는 빠른 복구와 유지하고 훨씬 더 안전

*온도 제어 알람을 보호하는 데 도움이 구성요소에서 가능한 부상

우리는 고용 지능형 버스를 기반 CNC 시스템을 갖추고 있으로 21.5 인치 터치 스크린이 있습니다. 그것은 쉽게 설치하고 디버깅 특징으로,신속하고 빠르게 데이터 전송,저장율 및 유지보수가 용이합니다.

HJ 시리즈 레이저 용접 기계는 주로 사용되는 용접을 위한 탄소 강철,스테인리스 스틸,알루미늄 및 기타 금속 물자입니다.

The HWlEiC HJ series provides cost-efficiency and high performance for various industries looking to upgrade metal processing methods and improve competitiveness.

시기 바랍 아래의 양식을 작성을 요청하는 견적,카탈로그 또는 기술 상담입니다.우리의 팀은 당신을 다시 얻을 24 시간 이내.

우리가 응답할 것입니다 당신은 24 시간 이내. 면한 긴급한 경우,추가하십시오 WhatsApp/WeChat:+86 15589913375. 또는 전화+86 15589913375 직접 있습니다.

*우리는 당신의 기밀을 존중하고 모든 정보 보호됩니다.

우리는 오직 귀하의 정보를 사용하여 귀하의 질문에 응답하고 결코 원치 않는 이메일로 보내거나 판촉 메시지입니다.

궁극적인 역동성과 효율성

내구성과 신뢰성

업그레이드 정밀도와 정확도

지능 및 사용 편의성

Safety&건강

다양한 자동화