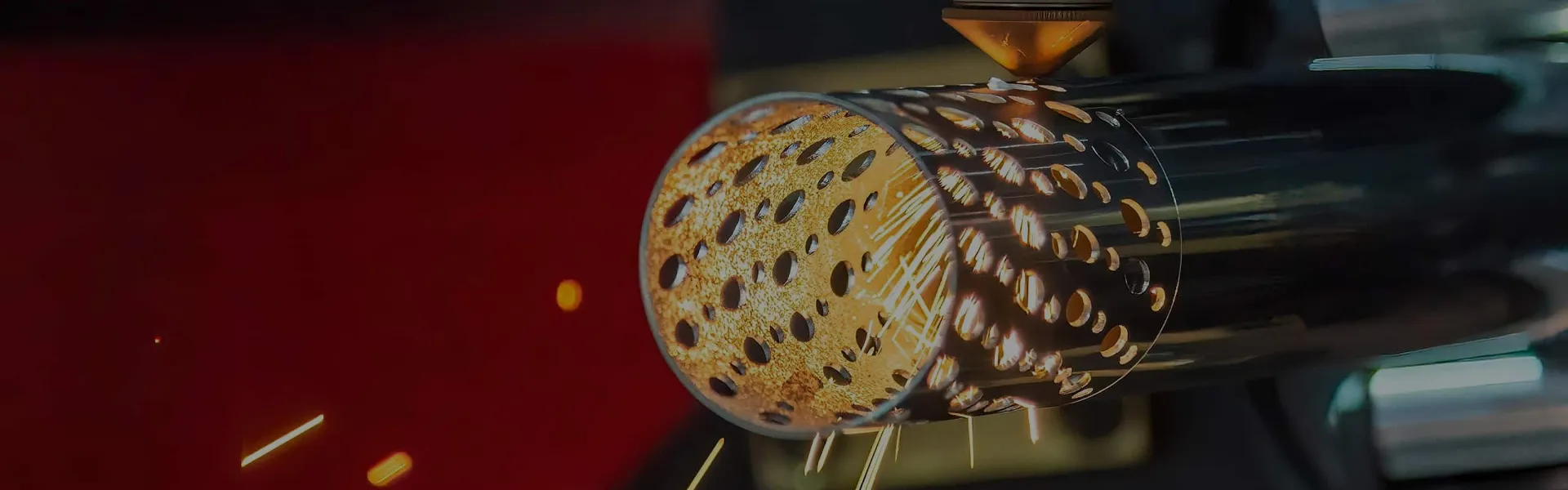

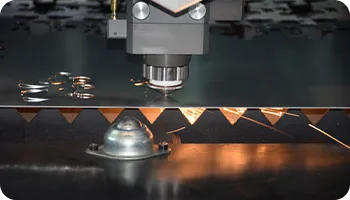

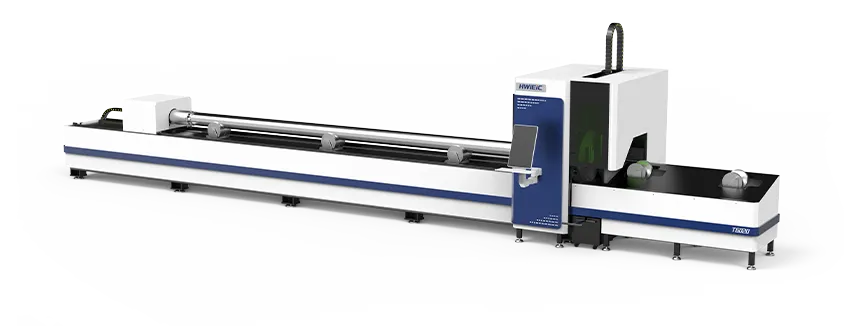

40kW Enclosed Exchange Platform Laser Cutting Machine(P Seires)Installed in Belarus, Boosting Local Manufacturing Upgrade

Minsk, Belarus – Recently, a 40kW enclosed exchange platform laser cutting machine, a high-end intelligent equipment for metal processing, was successfully installed and commissioned at a key Manufacturing Enterprise in Belarus. This installation marks a new milestone in the upgrading of local metal processing technology, bringing advanced efficient and precise production capabilities to Belarus' manufacturing industry, which is facing strong demand in infrastructure construction and agricultural machinery manufacturing.