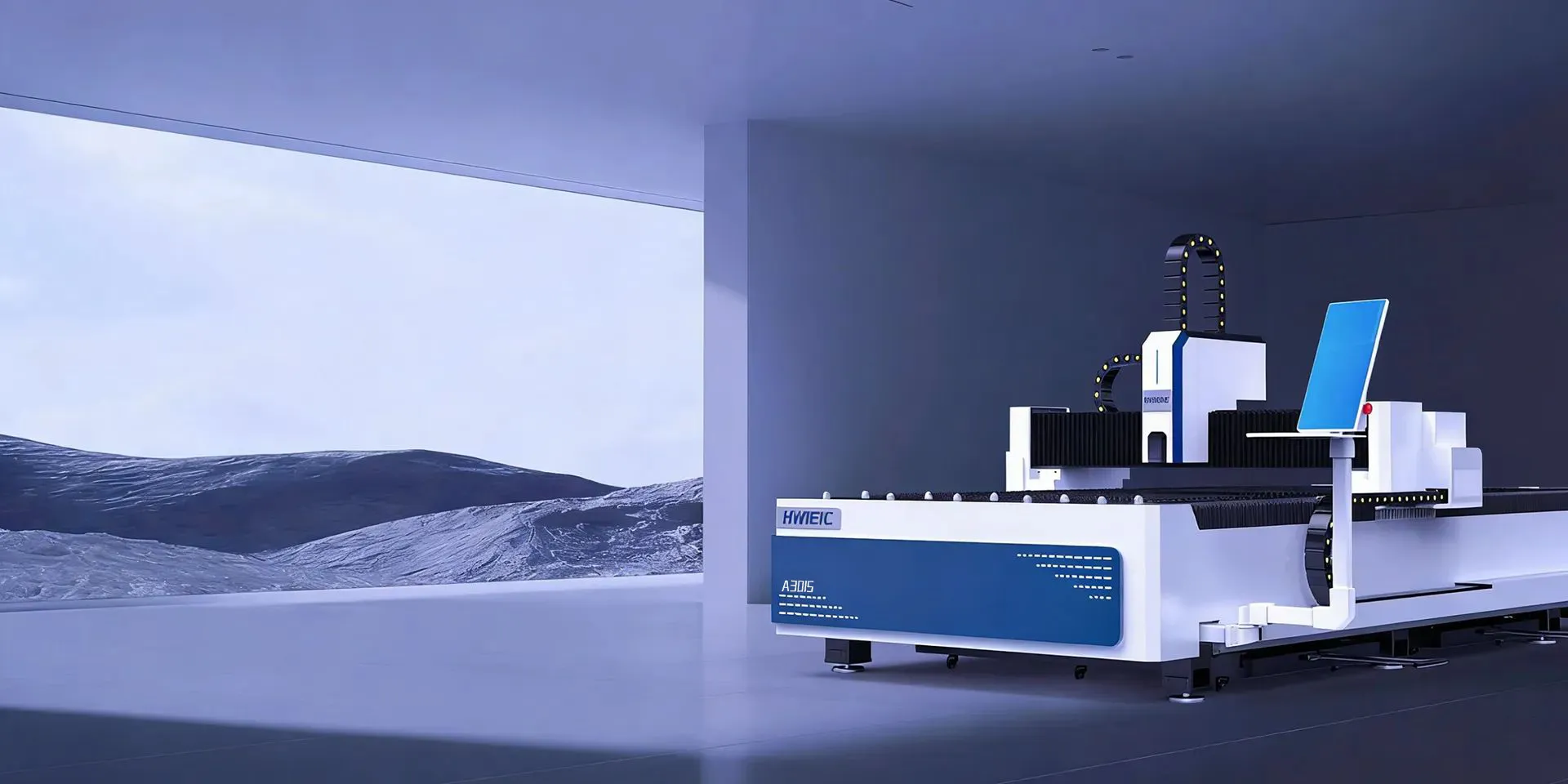

Performance based on robustness and, above all, reliability.

Deformation-free cutting of stainless steel, carbon steel, copper plate, aluminum plate, etc. Fast cutting speed, high precision, continuous cutting for a long time. Hole punching, slotting, cutting graphics, etc. Good beam quality, no burr, no slag, no black edge, no need for secondary processing Narrowest cutting seam, minimum heat-affected zone, minimal local deformation of the workpiece.

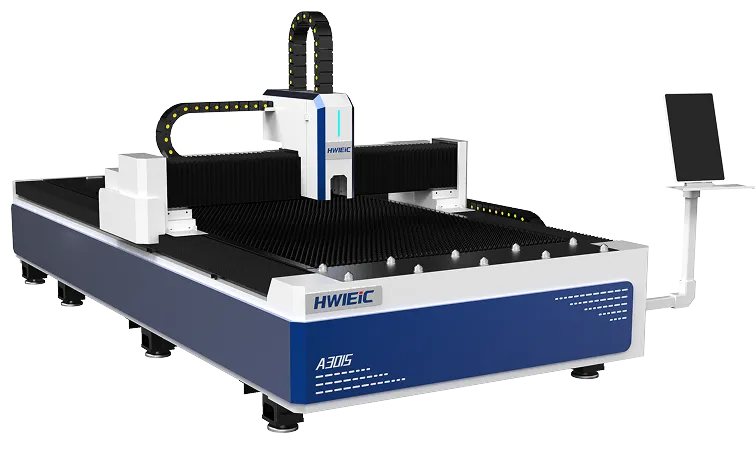

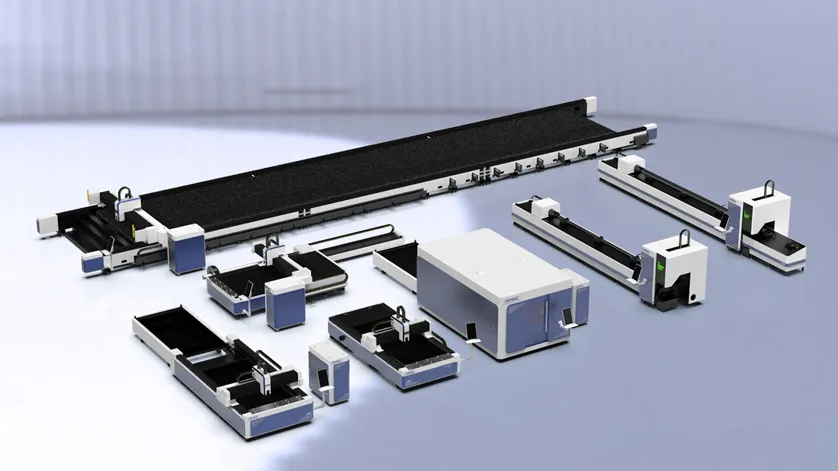

Metal sheet Laser Cutting Machine - Features & Configuration

This entry-level laser cutting machine for beginners offers precision and reliability, perfect for various metal cutting applications.

Auto-Focusing Laser Head

Automatic focusing reduces human intervention; the automatic focusing range is -12 to +10mm, and the focusing accuracy is 0.05mm. Collimation is enhanced with a protective lens to effectively protect the collimating lens.

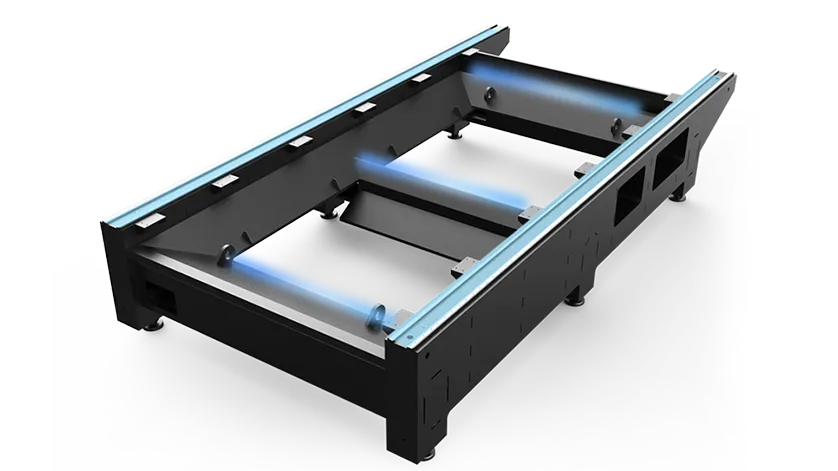

Welded One-piece Bed

Elevated platform with welded bed that undergoes thermal and aging treatment to relieve inner stress and make itself higher in rigidity and precision.

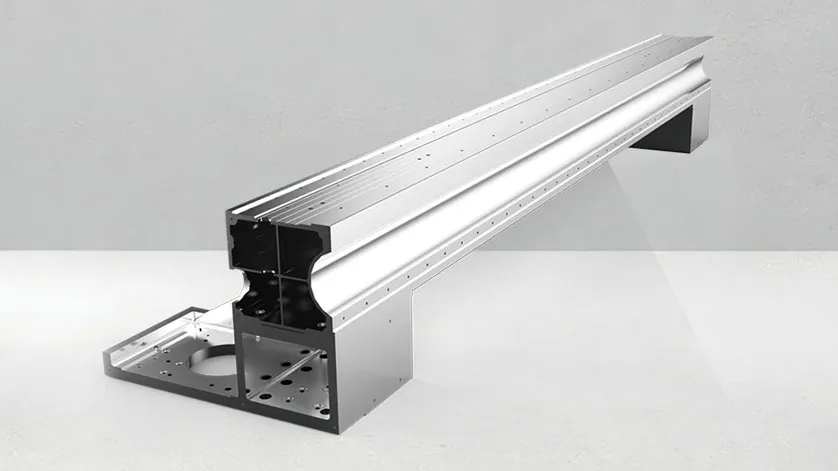

Aviation Aluminum Beam

With lightweight, low inertia and excellent dynamic performance, the beam can bring about high precision, no-load speed and working efficiency.

Control System

We employ intelligent bus-based CNC system equipped with 21.5-inch touch screen. It is easy to install and debug, featuring rapid and fast data transmission, low failure rate and easy maintenance.

Basic single plane laser cutting machine With Robust, Safe, Essential

Includes Following Features And Configuration

-

Gantry design + fully welded bed & profile beams: top-tier rigidity, stability, torsion & shock resistance.

-

Linear guides + rack-and-pinion drives: 80m/min max speed, ±0.03mm/m positioning & ±0.02mm repeat accuracy.

-

Jiaqiang CNC supports diverse plate processing; low-inertia AC servo motor for excellent dynamic performance.

-

±3 arcmin precision, ensuring stable and reliable transmission accuracy.

-

Laser integrated with main unit for consistent optical path stability.

-

CAD/CAM-compatible industrial computer enables easy drawing, programming, and maximum material savings.

-

Funnel-guided waste disposal into scrap cart for convenient regular cleaning.

-

X/Y axes with dust-proof covers + centralized/scheduled lubrication for extended service life.

-

Capacitive sensor-controlled Z-axis maintains focal distance; drawer-type lens base for easy maintenance.

-

Limit switches + hard stops + elastic buffers ensure safe X/Y/Z axis operation.

-

Closed optical path design effectively prolongs lens lifespan.

-

Automatic focusing system with sensitive and precise response.

-

Imported components, dual-gas option, 2Mpa nitrogen pressure for superior stainless steel cutting quality.

-

Ergonomic, attractive console for ATM-like easy machine operation.

Flexibility and efficiency

Its minimalist structure combines its main body, electrical cabinet, control system, air compressor, laser generator, and water chiller into one, so as to reduce space costs and improve workshop utilization.

Why hwieic ?

- Ultimate dynamics and efficiency

- Durability and reliability

- Upgraded precision and accuracy

- Intelligent & ease of use

- Safety & healthy

- Versatile automation

Product Performance

This machine is specifically developed for cutting sheet metal and is an economical entry-level model. Its compact structure and open design offer two different configurations. Both hardware and software have been upgraded to better meet users' actual needs.

| MODEL | A3015 | A4015 | A4020 | A6025 |

| Processing format | 3000mm*1500mm | 4000mm*1500mm | 4000mm*2000mm | 6000mm*2500mm |

| maximum acceleration | 1.2G | |||

| Maximum positioning speed | 100M | |||

| positioning accuracy | +0.02mm | |||

| Repeatability | +0.03mm | |||

| Adaptation power | 1500W-6000W | |||

| Focys method | automatic | |||

Product Performance

The reliable choice for lower costs with easy operation

- 1500W-6000W Laser power

- 3000*1500/4000*1500/4000*2000/6000*1500/6000*2500[mm] Sheet size

- 120 [m/min] Maximum no-load speed

- 2800[kg] Maximum Load

Tried-and-tested Design

• Its minimalist structure integrates the main body, electrical cabinet, control system, air compressor, laser generator, and water chiller into one, reducing space cost and improving workshop utilization.

• Open-style structure with no top cover offers a full view of the cutting process. Eye wheels on the left and front of the bed allow loading/unloading from left, right, and rear sides.

• Compact single-platform design with built-in laser generator occupies only 12 m².

• Integrated power cabinet separates strong and weak currents, reducing interference and enhancing stability and lifespan.

Welded One-piece Bed

* Elevated platform with welded bed that undergoes thermal and aging treatment to relieve inner stress and make itself higher in rigidity and precision.

* Modular tool bits are secured with screws for easy disassembly and replacement.

* Firebricks are used as fire prevention measures. Receiving funnel is detachable for easy use and change.

Aviation Aluminum Beam

With lightweight, low inertia and excellent dynamic performance, the beam can bring about high precision, no-load speed and working efficiency.

Control System

We employ intelligent bus-based CNC system equipped with 21.5-inch touch screen. It is easy to install and debug, featuring rapid and fast data transmission, low failure rate and easy maintenance.

Auto-Focusing Laser Head

Auto-focusing reduces human intervention; auto-focusing range -12~+10mm; focusing accuracy 0.05mm; collimation with added protective lens effectively protects the collimating lens.

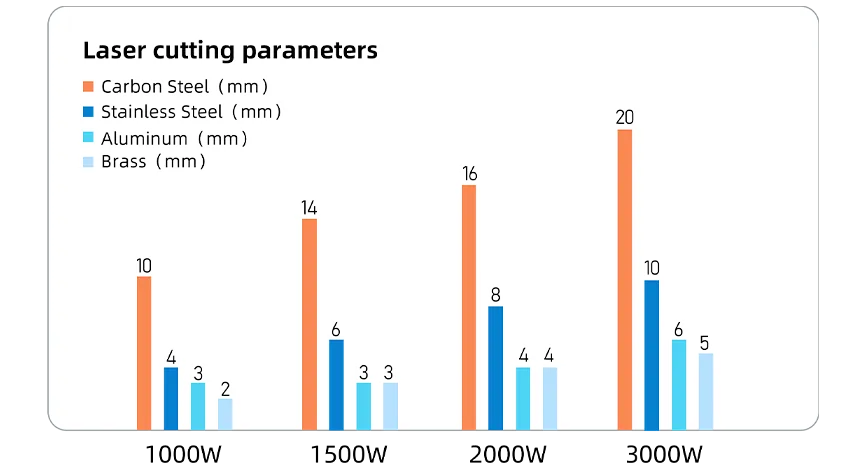

High quality results in all sheet thickness

As one of the classic models, the A series fiber laser cutting machine is mainly used for metal materials such as stainless steel, carbon steel, galvanized sheet, brass, aluminum, and various alloy plates

Customer Visit

The HWlEiC A series provides cost-efficiency and high performance for various industries looking to upgrade metal processing methods and improve competitiveness.

Request A Quote

Please fill out the form below to request a quote,catalog,or technical consultation.Our team will get back to you within 24 hours.

Get a Quote

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 ******,. Or call +86 ****** directly.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.

Products

POWER TOOLS

Ultimate dynamics and efficiency

Durability and reliability

Upgraded precision and accuracy

Intelligent & ease of use

Safety & healthy

Versatile automation