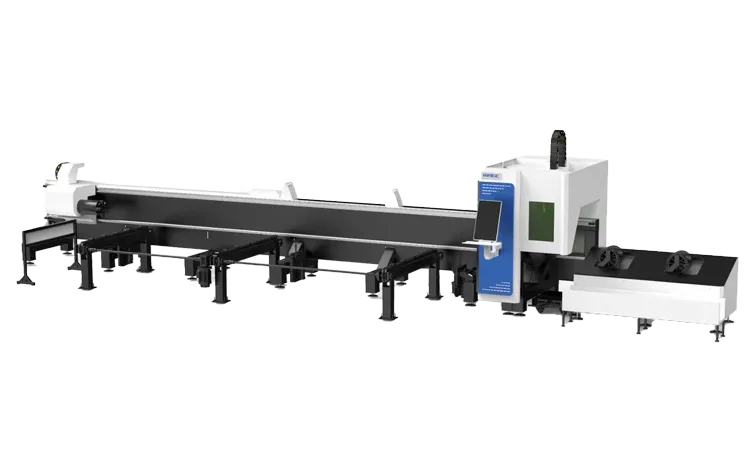

TE Series

Laser Tube Cutter with Dual Chucks

TE Series, With Super-High Cutting Ability And Dynamic Performance, Can Cut Various Small And Large Tubes At High Speed. Such Outstanding Capability Profits From Its High-Level Configurations.

TE series, with super-high cutting ability and dynamic performance, can cut various small and large tubes at high speed. Such outstanding capability profits from its high-level configurations.

With advanced configurations, TE series come standard with two chucks to cut tubes with ultra-short tailing. For small tube, there is no overburning or adhering slag. As for large tube, the cutting is at fast speed. It enjoys fast shipment and delivery, and is widely used in rail transit, automobile production, construction machinery, agricultural and forestry machinery, etc.

* Max Tube length: 12000mm * Round tube: Φ15~360mm, square tube: □15*15~360*360mm, rectangular tube: diagonal line/side length≤360mm

With precision self-centering chucks and a small tailing design, tubes are clamped securely and cut with minimal waste.

Powered by high‑performance in‑house and globally renowned components, it delivers cutting speeds up to 70% faster than comparable models.

Upgraded intelligent software monitors all running indexes in real time, reducing manual intervention and minimizing misoperation

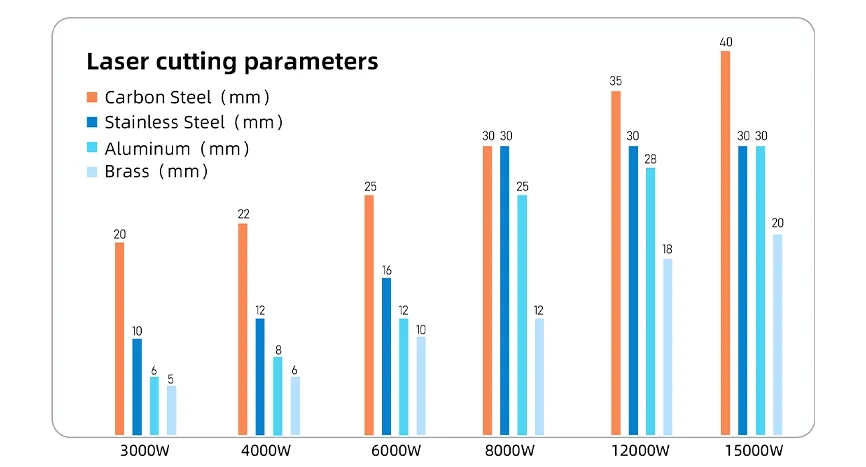

New optical elements and multi-layer coatings enable easy cutting of stainless steel, aluminum alloy, and other metals.

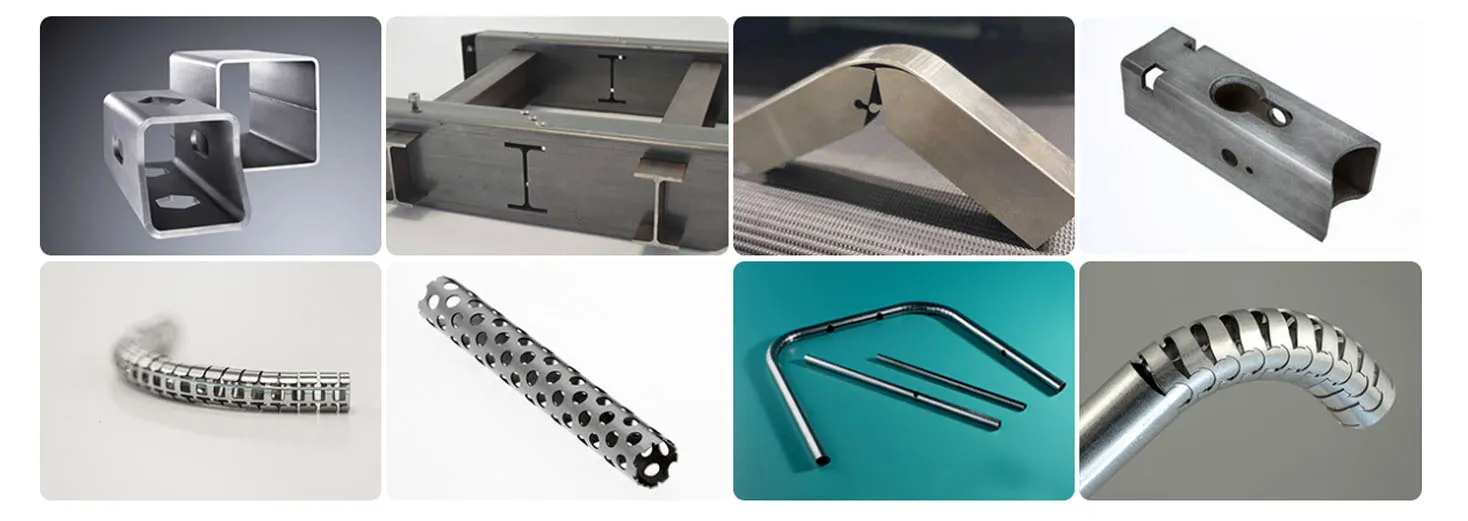

It is used to cut round, square, rectangular, oval tube, I-beam, as well as channel, angle tube, C-profile and H-shaped steel at high precision.

Cuts round, square, rectangular, and special-shaped tubes up to 12000mm in length and max Ø360mm in diameter.

Reduces tailing with smart tailing craft and precision self-centering chucks for minimal material waste.

Achieves 70% faster cutting speed with up to 150m/min no-load speed and 180r/min chuck rotation.

Real-time intelligent software minimizes manual intervention and prevents operational errors.

Effortlessly cuts stainless steel and aluminum alloy tubes using anti-reflective optical laser components.

Handles I-beams, channels, angle irons, oval tubes, and H-profiles with high precision.

Semi-enclosed structure provides safe and ergonomic operation, with high-integration control console.

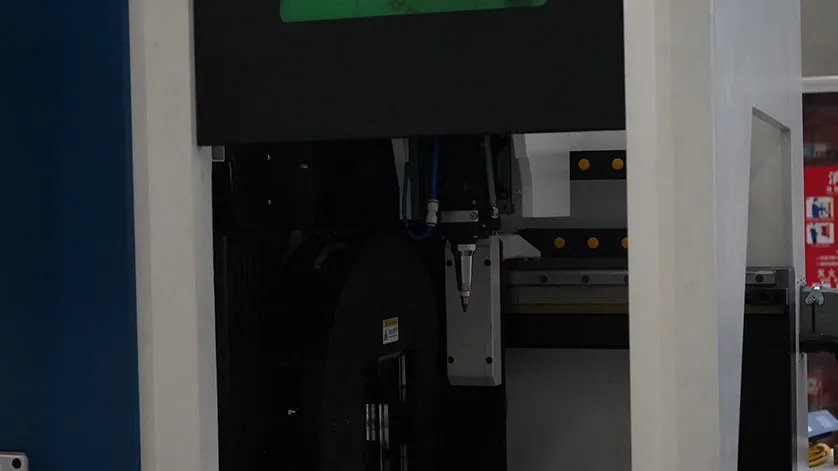

Compact self-developed cutting head features water cooling and triple dust-proof protective lenses.

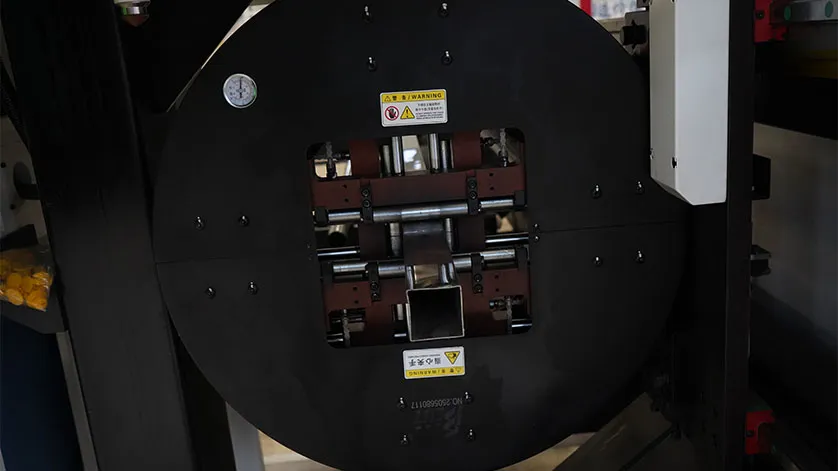

Square-design front chuck clamps square and rectangular tubes more securely and effectively.

Four-cylinder smart claw system enhances grip on heavy tubes, ensuring cutting accuracy.

Built-in debris and ash removal system reduces blockages and manual maintenance time.

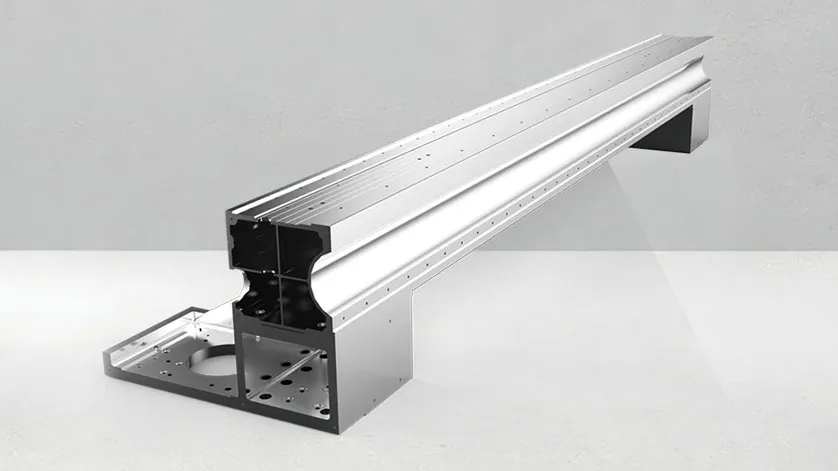

Machine bed is precision-welded, stress-relieved, and finished to ensure rigidity and long-term durability.

Ensure safety, maximize material usage, and streamline operations for superior productivity and cost savings.

TE series, with super-high cutting ability and dynamic performance, can cut various small and large tubes at high speed. Such outstanding capability profits from its high-level configurations.

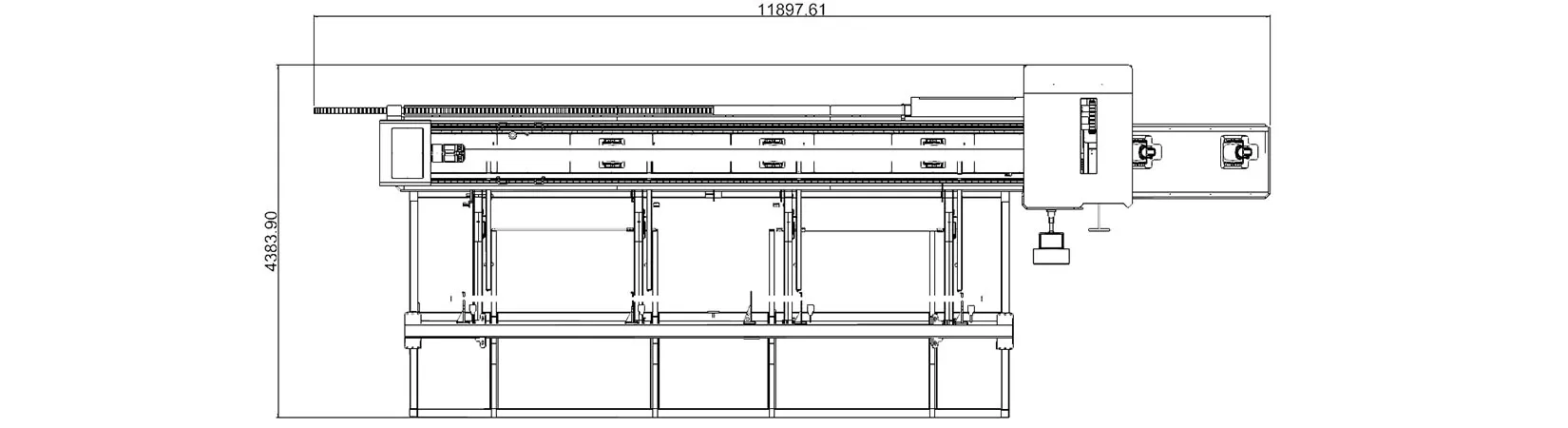

| Model | TE12023 | TE6023 |

| Tube Size Range | Round tube: 10–360 mm Square tube: to 360 × 360 mm | Round tube 10-245mm Squaretube245*245mm |

| Maximum Machinable Tube Length | 12,000 mm | 6000mm |

| Maximum Tube Weight | 1.5 t | 300kg |

| Machine Dimensions | 29,000 × 2,300 × 3,000 mm | 9000*1800*2500mm |

| Overall Machine Weight | 13,000 kg | 2750kg |

The reliable choice for lower costs with easy operation

The whole machine uses semi-enclosed structure to keep your operation safe and comfortable. For some models, control console is highly integrated with distribution cabinet, at a high level of integration.

Automation (Optional)

Semi-automatic Chained Loading Device

Tube length (min-max): 4000-12000mm

* Front chuck is designed as square, clamping a wider range of square and rectangular tubes

* Utilize four independent cylinders and smart claws for more stable clamping of heavy tubes

* The automatic debris and ash removal device is used for lessening jamming and lowering manual cleaning frequency

* Small in size and light in weight. Its optical fiber core is much smaller, which contributes to laser beam concentration at better quality.

* Its electro-optical conversion rate reaches over 40%. Electric power and cutting costs will be greatly saved for users.

We employ intelligent bus-based CNC system equipped with 21.5-inch touch screen. It is easy to install and debug, featuring rapid and fast data transmission, low failure rate and easy maintenance.

With lightweight, low inertia and excellent dynamic performance, the beam can bring about high precision, no-load speed and working efficiency.

With unique small tailing craft and precision self-centering chucks, tubes may not only be clamped at high precision, but also facilitate the tube cutting with much shorter tailing.

As one of the classic models, the TE series fiber laser cutting machine is mainly used for metal materials such as stainless steel, carbon steel, galvanized sheet, brass, aluminum, and various alloy plates

The HWlEiC TE series provides cost-efficiency and high performance for various industries looking to upgrade metal processing methods and improve competitiveness.

Please fill out the form below to request a quote,catalog,or technical consultation.Our team will get back to you within 24 hours.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 15589913375. Or call +86 15589913375 directly.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.

Ultimate dynamics and efficiency

Durability and reliability

Upgraded precision and accuracy

Intelligent & ease of use

Safety & healthy

Versatile automation