Christmas Greetings from HWlEiC Laser

As the Christmas season arrives, all of us at HWlEiC Laser would like to extend our warmes…

learn more

Manufacturers today face rising costs, tighter tolerances, and pressure to produce faster without sacrificing quality. Traditional cutting methods struggle to keep up. Laser technology changes the equation—delivering speed, precision, and stability that modern manufacturing demands.

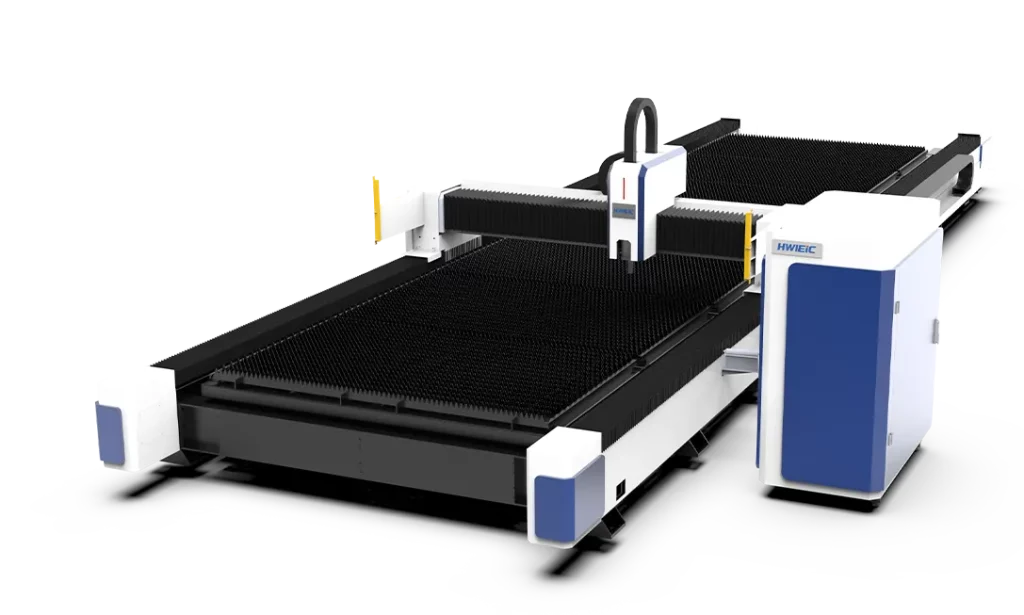

A laser cutting machine uses a focused laser beam to cut, engrave, or mark materials with high precision and speed. Compared to mechanical cutting, laser cutting offers cleaner edges, higher efficiency, and better consistency. It is widely used in automotive, aerospace, electronics, and metal processing industries to improve productivity, accuracy, and long-term manufacturing reliability.

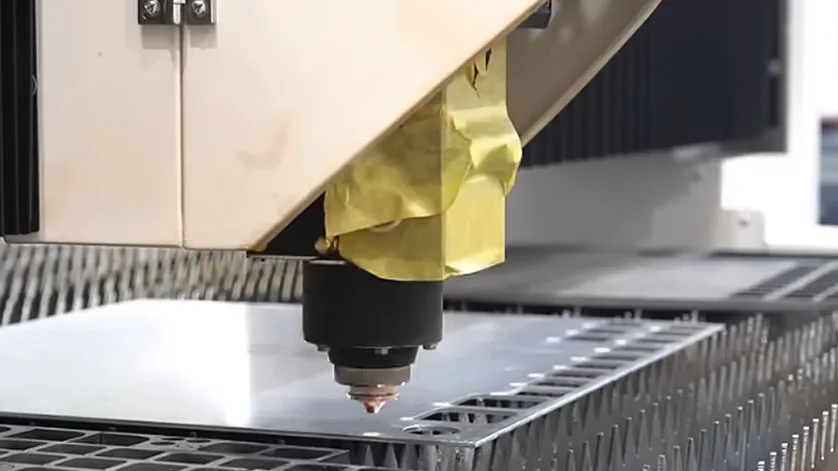

A laser cutting machine is a cutting machine that uses a concentrated laser beam to cut and engrave materials without physical contact. Unlike traditional cutter machines, the laser cutter focuses energy on a small laser spot, melting or vaporizing material with extreme accuracy.

Laser cutting works by controlling the laser beam through CNC laser software. The system moves precisely across the work area, ensuring consistent results even during high-speed operation. Because there is no mechanical wear, laser machines maintain accuracy over long production cycles.

For manufacturers looking for stable, repeatable results, laser technology offers a clear advantage. Machines can cut complex shapes, perform deep engraving, and switch between cutting and engraving with minimal setup time.

Many manufacturers are replacing mechanical cutting machines with laser cutters for one simple reason: efficiency.

Laser cutting delivers:

Faster engraving and cutting speed

Cleaner edges with minimal post-processing

Higher consistency across batches

Lower total cost of ownership

Traditional methods struggle with tool wear, vibration, and limited flexibility. A precision laser system avoids these issues by using controlled laser power and advanced motion systems.

For large and medium-sized manufacturing enterprises, laser cutting reduces processing time by 20–30% on average, while maintaining tighter tolerances. This combination makes laser machines ideal for intelligent manufacturing environments.

Precision laser systems deliver accuracy that mechanical cutters cannot match. With controlled laser output power and advanced motion control, machines can achieve tolerances as low as ±0.01 mm.

Key advantages include:

Laser cutting speed depends on material thickness, laser power, and laser type. High-power fiber laser systems maintain speed even on thick metals, while CO2 laser cutters excel at smooth edges on softer materials.

This balance of speed and precision is why laser cutting machines dominate high-precision industries.

Laser cutters are capable of cutting a wide range of materials, including:

Laser engraving capabilities extend to metal engraving, engraving wood, and marking coated surfaces. With the right configuration, machines can cut and engrave without changing hardware.

This versatility allows manufacturers to respond quickly to changing orders and production demands.

When choosing the right laser, manufacturers should consider:

Buying a laser is not just about power. It’s about system stability, long-term reliability, and technological security. For government-led projects and high-precision industries, controllable core technology and supply chain stability matter just as much as performance.

Investing in a laser engraver or cutting machine should always align with long-term production strategy.

Investing in a laser cutting machine is a long-term decision. While initial costs may be higher than traditional equipment, the return on investment comes from:

For enterprises seeking secure and intelligent manufacturing solutions, the value lies in stability, upgrade potential, and partnership with a supplier who understands industrial pain points.

At HWlEiC Laser, we approach every project as a system solution—combining laser cutting, welding, cleaning with automation and data integration.

Laser cutting machines are no longer optional tools—they are the backbone of intelligent manufacturing. For manufacturers seeking efficiency, precision, and long-term reliability, laser technology delivers measurable competitive advantages.

If you are looking for a laser cutting partner who understands industrial-level challenges, HWlEiC Laser is ready to help you build smarter, faster, and more resilient production systems.

As the Christmas season arrives, all of us at HWlEiC Laser would like to extend our warmes…

learn more

Independent electrical cabinet: the electrical part is assembled with independent electric…

learn more

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 ******,. Or call +86 ****** directly.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.

Ultimate dynamics and efficiency

Durability and reliability

Upgraded precision and accuracy

Intelligent & ease of use

Safety & healthy

Versatile automation