FT Series

Single platform plate and tube laser cutting machine

This Affordable Metal Laser Cutting Machine Is Perfect For Cutting Both Sheets And Tubes With High Precision And Efficiency, Ideal For Various Manufacturing Needs.

The FT series can quickly cut sheet metal and tubing, mostly used in the fitness equipment and furniture industries.

It can cut both sheet and tube. With it, you will take more cutting demands easy, save 50%+ space and halve your costs of purchase at least, gaining more advantages over peers while exploring new markets and customers.

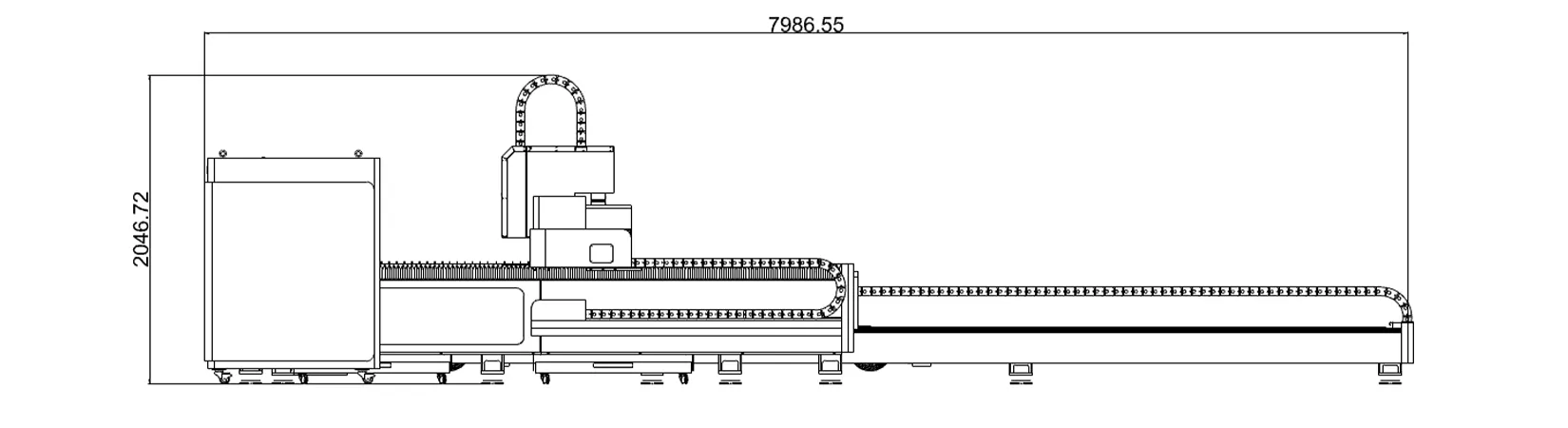

Cut 3050*1530-8050*2030mm sheet, Φ20-230mm and 6000mm long tube

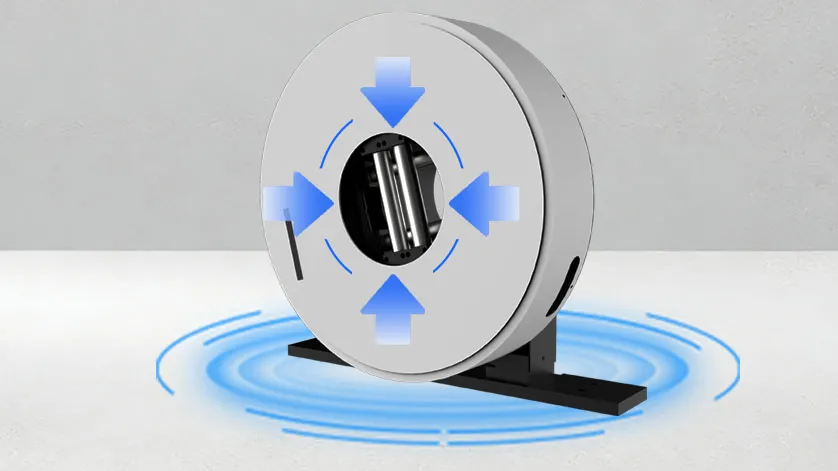

Its pneumatic chuck is self-centering and can clamp tubes of different shape, size and weight firmly, with no slip. Tube waste will be minimized.

Users are allowed to switch between sheet cutting and tube cutting at will. It works dozens of times faster than the tradition.

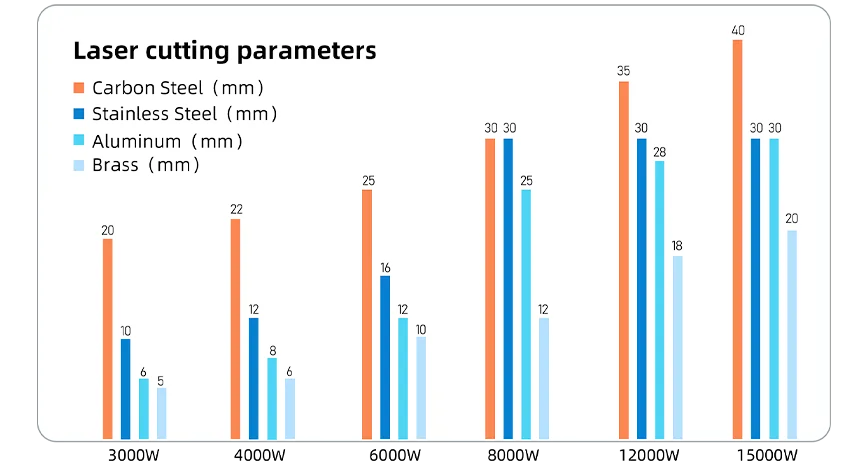

Deal with carbon, stainless steel, AL alloy, brass, galvanized sheet, silicon steel sheet, electrolytic sheet, titanium and manganese alloy

Easily process carbon steel, stainless steel, aluminum alloy, brass, galvanized sheet, silicon steel, titanium, and manganese alloy.

Self-centering pneumatic chuck firmly clamps various tube shapes and sizes without slipping, minimizing tailing waste.

Seamlessly switch between sheet and tube cutting, performing dozens of times faster than traditional methods.

One operator can manage multiple machines at once, reducing labor costs and boosting production efficiency.

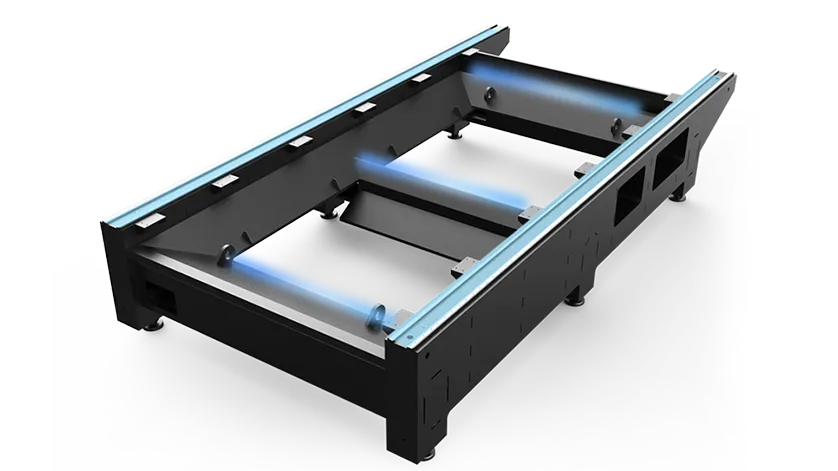

Open-style structure without top cover or side baffles allows loading/unloading from front, rear, and both sides.

Full visibility of the cutting workflow enables operators to respond quickly and reduce unplanned downtime.

Designed for cutting thin sheets (≤20mm) and small-diameter tubes with a compact single-platform layout.

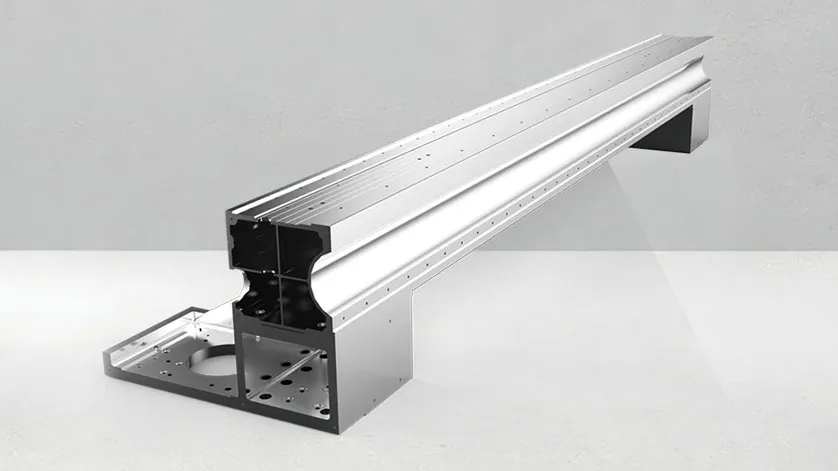

Aerospace-grade aluminum alloy beam ensures high precision, low inertia, and fast dynamics (max 100m/min, 1G acceleration).

Semi-hollow machine tool with isolated internal structure prevents thermal interference, ensuring cutting accuracy

Machine bed remains rigid and crack-free even after long-term high-temperature use, thanks to 7-stage thermal treatment.

Ensure safety, maximize material usage, and streamline operations for superior productivity and cost savings.

It can cut both sheet and tube. With it, you will take more cutting demands easy, save 50%+ space and halve your costs of purchase at least, gaining more advantages over peers while exploring new markets and customers.

| MODEL | FT8025 | FT6025 | FT6015 | FT4020 | FT3015 |

| Processing format | 8000mm*2500mm | 6000mm*2500mm | 6000mm*1500mm | 4000mm*2000mm | 3000mm*1500mm |

| Tube size range | Round tube Φ20-Φ210mm Square tube □20 – □150mm |

||||

| Electric chuck maximum load | 200kg | ||||

| Requirements for tubes | 0.8mm-10mm tube wall tdickness | ||||

| Max. lengtd of tube | 6000mm | ||||

The reliable choice for lower costs with easy operation

FT series reduces the need for multiple machines, offering both sheet and tube cutting capabilities in one unit.

In the absence of top cover and four-directional baffles, users can load and unload from front, rear and both sides at will

With open-style structure, operators are crystal clear to whole work process to deal with emergencies and avoid needless downtime

Aim at cutting thin sheet (≤20mm) and relatively small tube. Simply designed, but high in cost performance in spite of single platform

Light in weight and small in inertia, standing out in dynamic performance. The max no-load speed and acceleration reach up to 100m/min and 1G respectively

This semi-hollow machine tool is internally unconnected to cut off heat transfer and any effect on cutting precision

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like 600° high annealing

We employ intelligent bus-based CNC system equipped with 21.5-inch touch screen. It is easy to install and debug, featuring rapid and fast data transmission, low failure rate and easy maintenance.

Small in size and light in weight, with all-optical and water-cooling design

Its pneumatic chuck is self-centering and can clamp tubes of different shape, size and weight firmly, with no slip. Tube waste will be minimized.

As one of the classic models, the ET series fiber laser cutting machine is mainly used for metal materials such as stainless steel, carbon steel, galvanized sheet, brass, aluminum, and various alloy plates

The HWlEiC FT series provides cost-efficiency and high performance for various industries looking to upgrade metal processing methods and improve competitiveness.

Please fill out the form below to request a quote,catalog,or technical consultation.Our team will get back to you within 24 hours.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 15589913375. Or call +86 15589913375 directly.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.

Ultimate dynamics and efficiency

Durability and reliability

Upgraded precision and accuracy

Intelligent & ease of use

Safety & healthy

Versatile automation