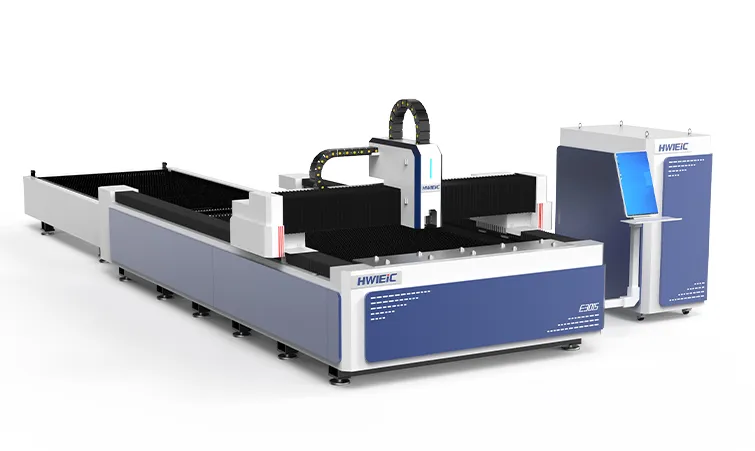

E Series

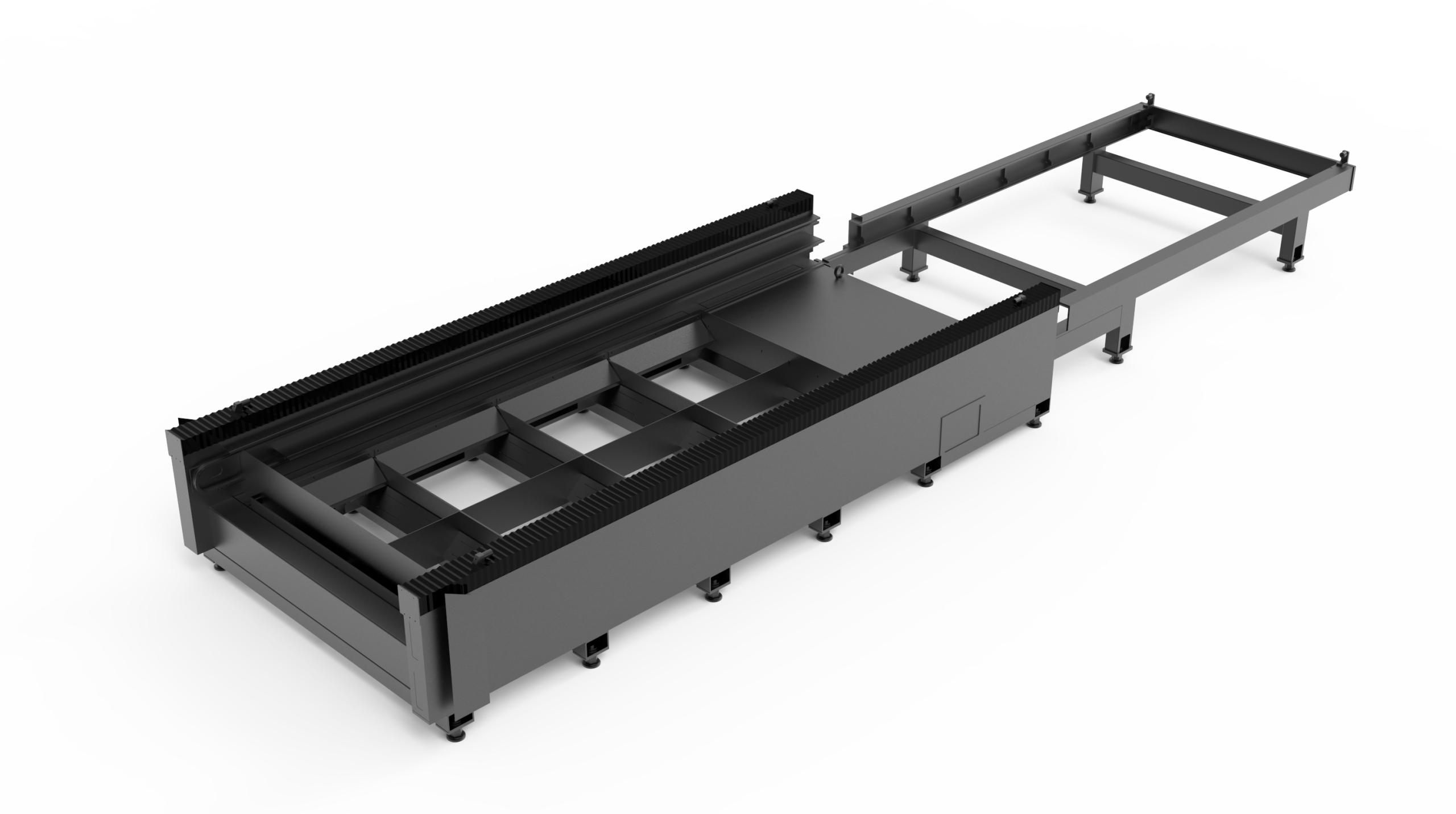

Exchange platform fiber laser cutting machine

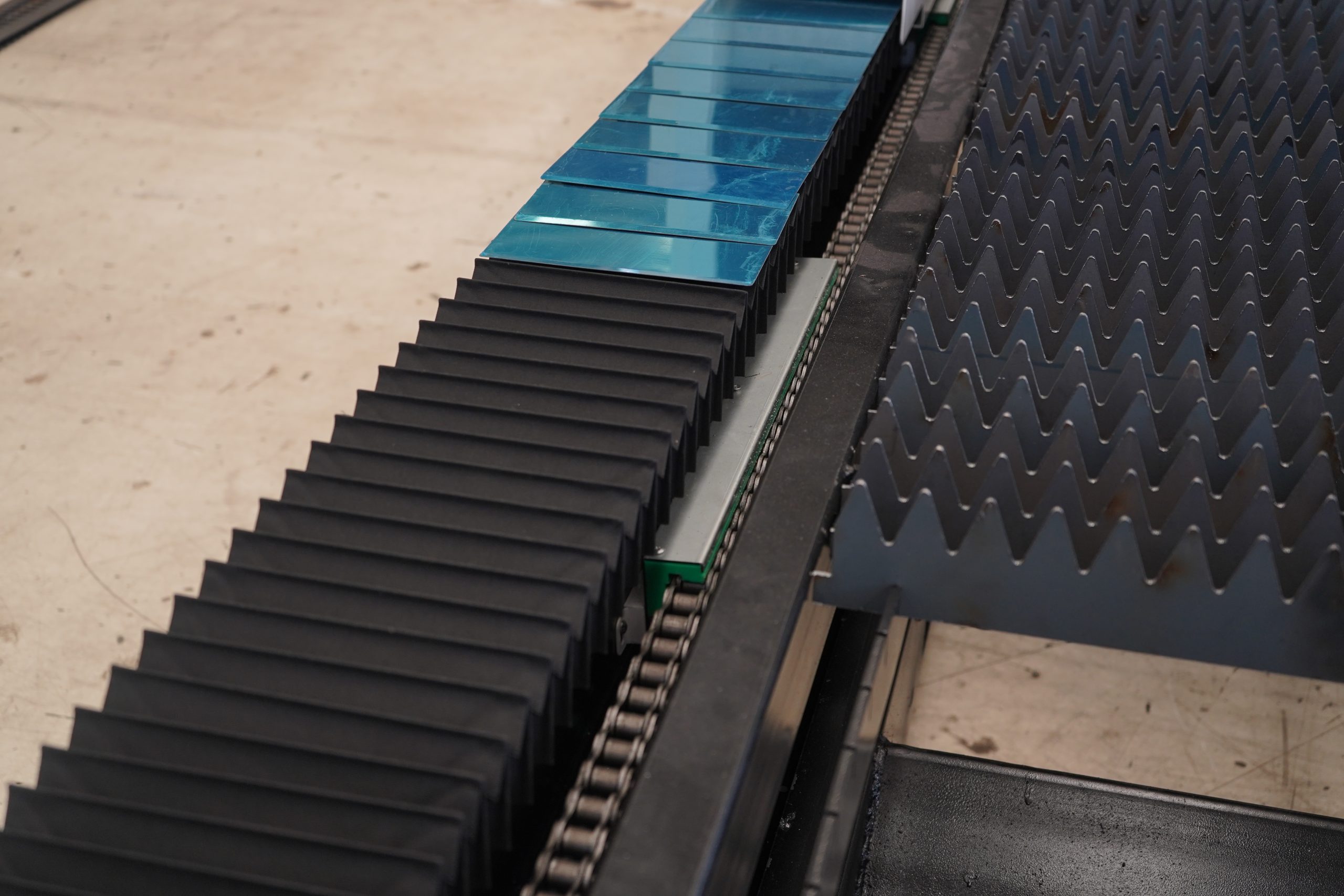

High-Speed Parallel Exchange Platformdesign, Simultaneous Exchange Of Two Worktables,Stable And Reliable Transmissior Mode, Shorter Exchange Time.

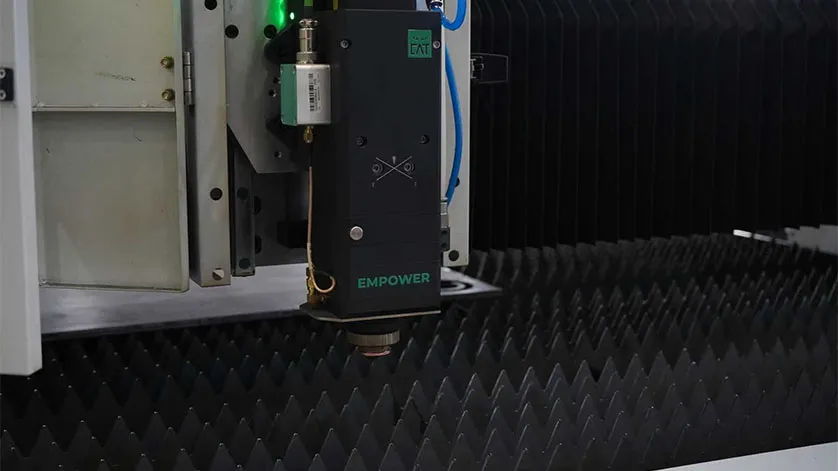

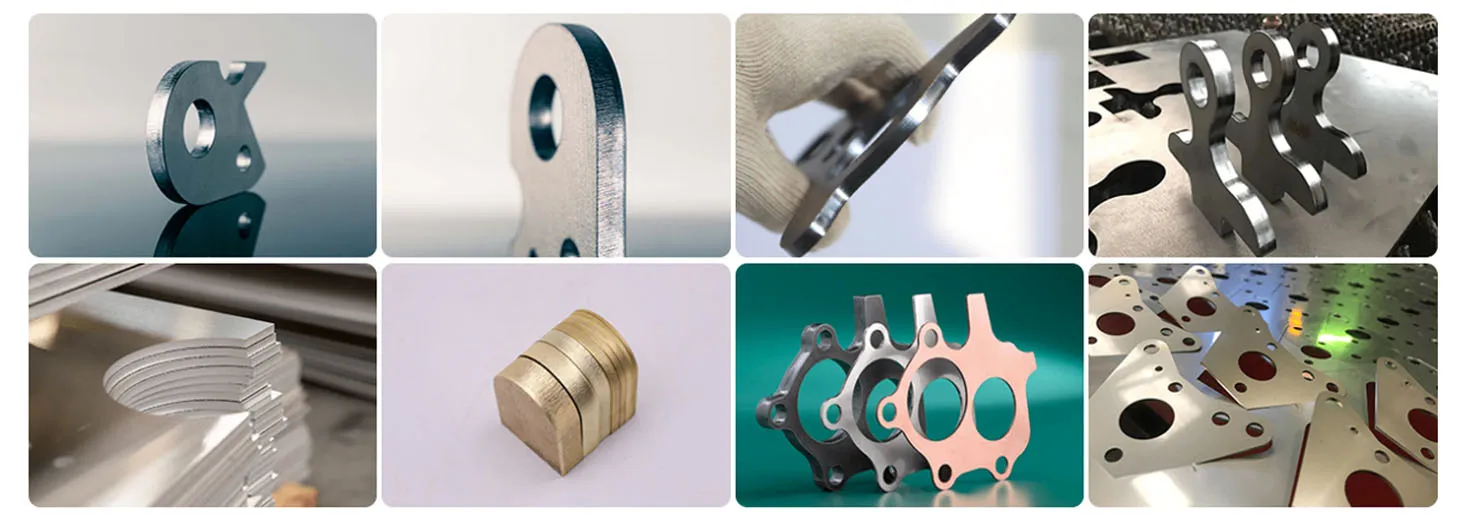

Deformation-free cutting of stainless steel, carbon steel, copper plate, aluminum plate, etc. Fast cutting speed, high precision, continuous cutting for a long time. Hole punching, slotting, cutting graphics, etc. Good beam quality, no burr, no slag, no black edge, no need for secondary processing Narrowest cutting seam, minimum heat-affected zone, minimal local deformation of the workpiece.

This highly cost-effective machine is equipped with double exchange platforms, but its compact size can satisfy some customers who prefer to high power but lack of space.

Compact footprint with high space efficiency, smoke-free cutting enabled by intelligent dust removal, and reinforced fireproof design with graphene and red copper.

We use integrated electronic components & precision guide rail and racks (100% match) to enable high acceleration (1.2G) and positioning accuracy (±0.05mm).

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like 600° high annealing

This professional CNC system is internally installed with many functions, so as to lower failure rate and allow for easy use & maintenance.

Small footprint, high efficiency—only 19m² to unleash full cutting power.

Dual exchange platform in compact form—perfect for limited factory space.

Hollow bed + graphene/copper fire protection—safe, stable, and thermally resistant.

Intelligent spiral dust removal—enables smoke-free, eco-friendly cutting.

Accelerates up to 1.2G with micron-level precision (±0.05mm).

Industrial-grade guide rail + rack, perfectly matched for smoother motion.

Stable under heat—machine base annealed at 600°C, 7-stage processing.

Green hands welcome—intuitive interface, easy for anyone to operate.

Advanced CNC system, pre-installed with diagnostics & automation logic

Deslag piercing ensures cleaner holes and aesthetic finishes.

Self-adjust vibration control—cuts thin sheets with flawless precision.

Micro-joint smoothing—safe unloading, clean edges, zero rework.

Energy-saving drive components lower consumption and maintenance.

Designed for sustainable production with smart dust and fire control.

Durable under long use, deformation-free even in 24/7 production lines.

Its minimalist structure combines its main body, electrical cabinet, control system, air compressor, laser generator, and water chiller into one, so as to reduce space costs and improve workshop utilization.

Performance Benefits . It can cut various metal sheets at fast speed and high quality.

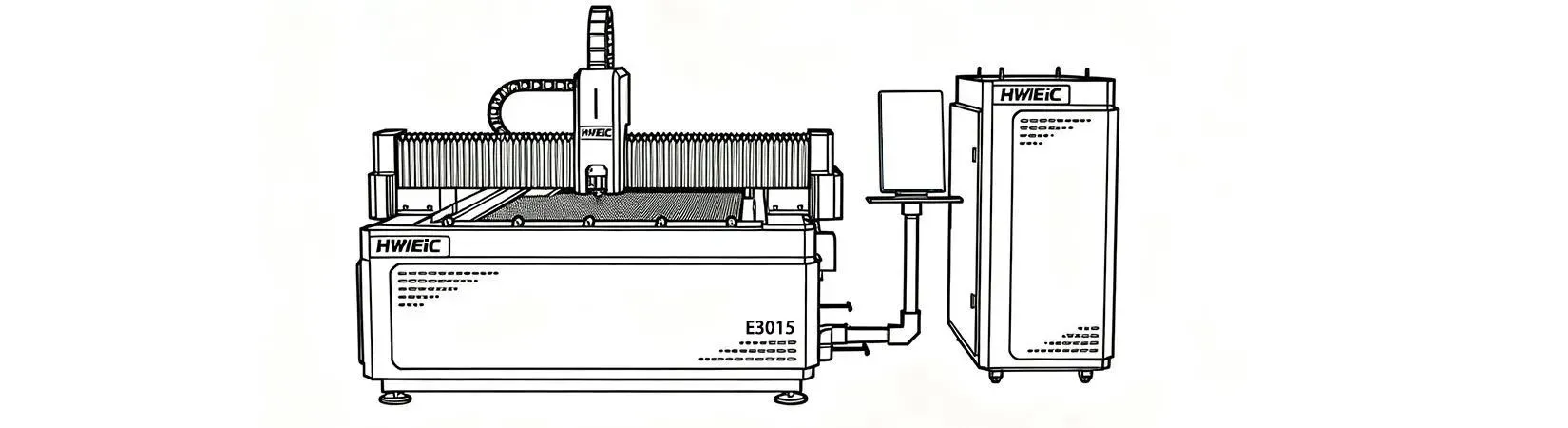

| MODEL | E12025 | E10025 | E8025 | E6025 | E4020 | E 3015 |

| Processing format | 12000mm*2500mm | 10000mm*2500mm | 8000mm*2500mm | 6000mm*2500mm | 4000mm*2000mm | 3000mm*1500mm |

| Overall weight | 23000kg | 18000kg | 14000kg | 10000kg | 6500kg | 4500kg |

| maximum acceleration | 1.5G | |||||

| Maximum positioning speed | 100M | |||||

| positioning accuracy | +0.02mm | |||||

| Repeatability | +0.03mm | |||||

| Adaptation power | 1.5-50KW | |||||

The reliable choice for lower costs with easy operation

Cover a small area (only 19m2) for high utility rate of space

Adopt hollow machine tool, further thickened tool bits and graphene/red copper as fire prevention

Allow for free-smoke cutting because of intelligent spiral negative-pressure dust removal system

High-speed parallel exchange platform design, simultaneous exchange of two worktables, stable and reliable transmission mode, shorter exchange time.

Ease of transportation while reducing later maintenance costs.

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like 600° high annealing

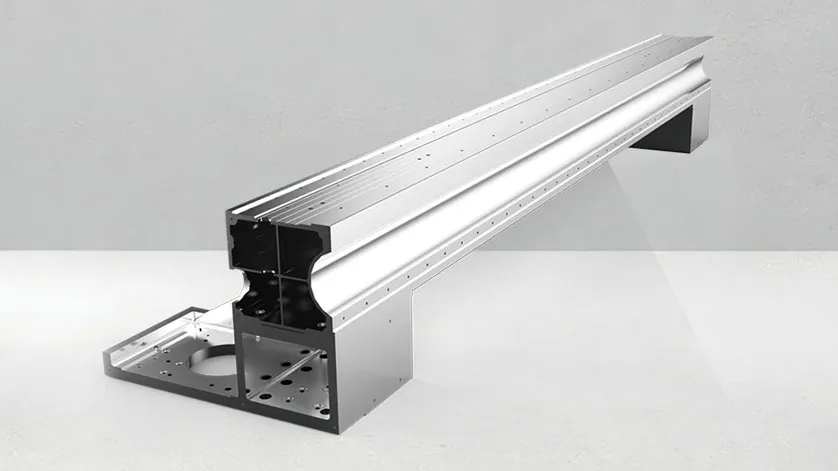

With lightweight, low inertia and excellent dynamic performance, the beam can bring about high precision, no-load speed and working efficiency

We use integrated electronic components & precision guide rail and racks (100% match) to enable high acceleration (1.2G) and positioning accuracy (±0.05mm).

We employ intelligent bus-based CNC system equipped with 21.5-inch touch screen. It is easy to install and debug, featuring rapid and fast data transmission, low failure rate and easy maintenance.

Small in size and light in weight, with all-optical and water-cooling design

As one of the classic models, the A series fiber laser cutting machine is mainly used for metal materials such as stainless steel, carbon steel, galvanized sheet, brass, aluminum, and various alloy plates

The HWlEiC E series provides cost-efficiency and high performance for various industries looking to upgrade metal processing methods and improve competitiveness.

Please fill out the form below to request a quote,catalog,or technical consultation.Our team will get back to you within 24 hours.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 15589913375. Or call +86 15589913375 directly.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.

Ultimate dynamics and efficiency

Durability and reliability

Upgraded precision and accuracy

Intelligent & ease of use

Safety & healthy

Versatile automation