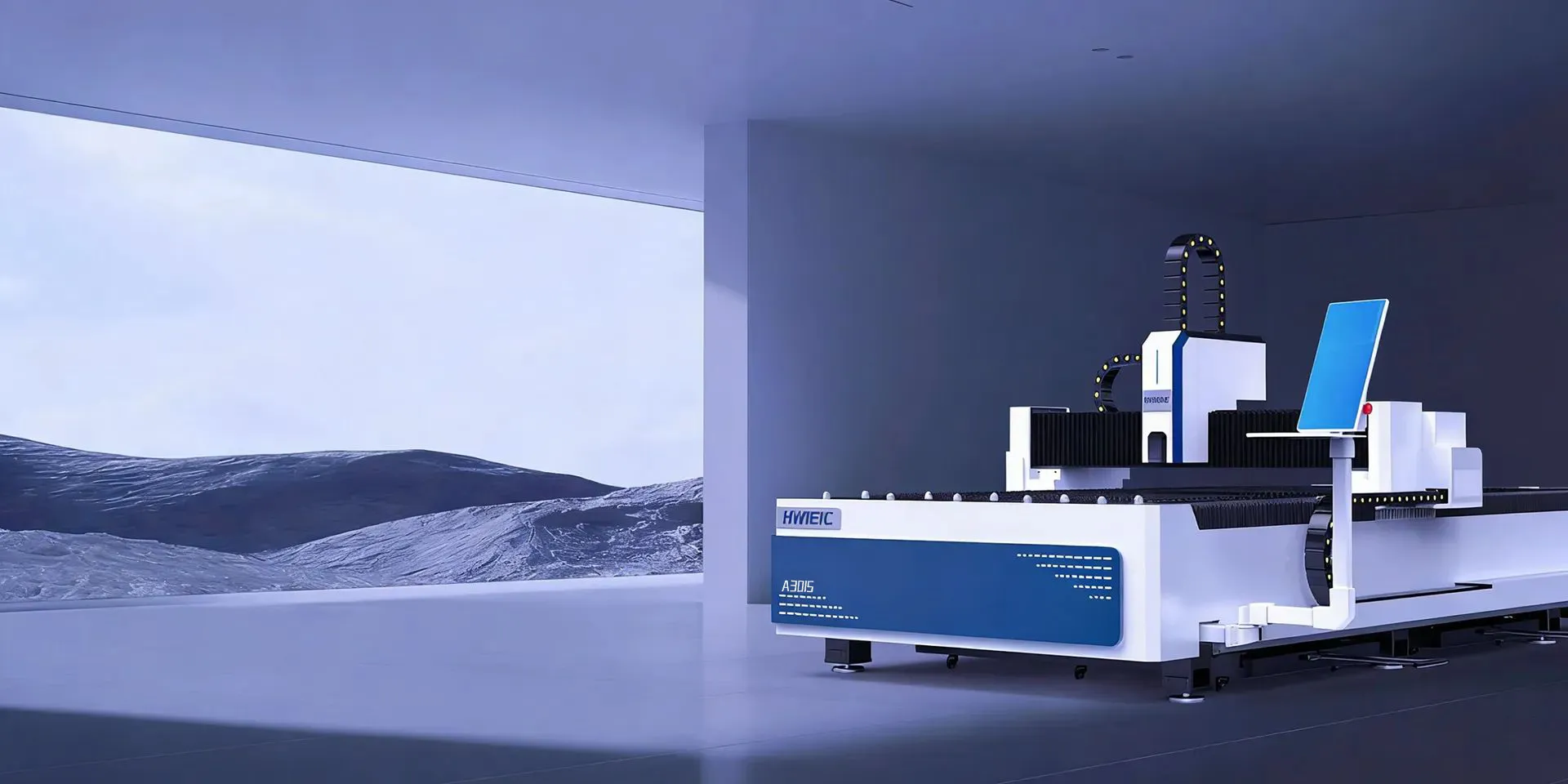

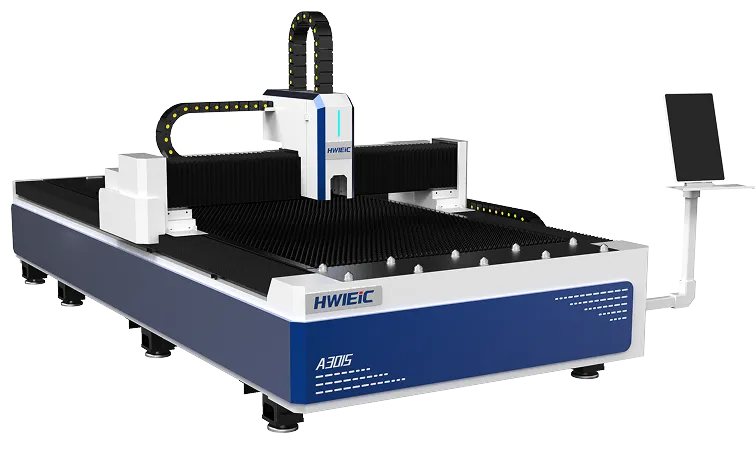

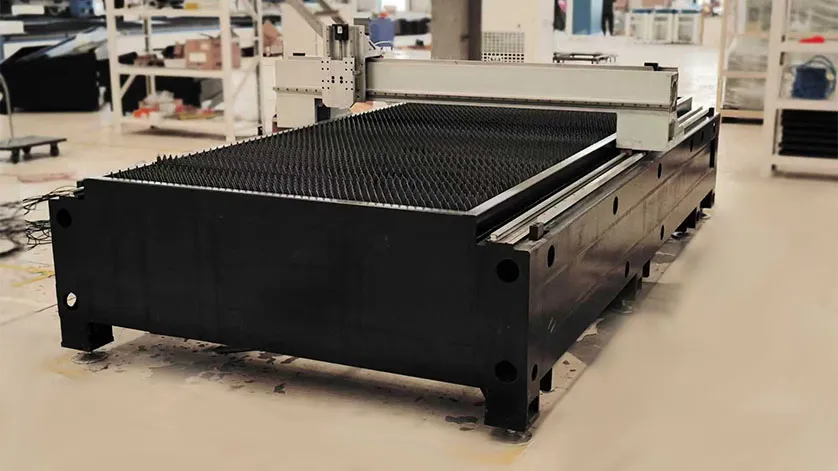

A Series

Basic single plane laser cutting machine

This machine is specifically developed for cutting sheet metal and is an economical entry-level model. Its compact structure and open design offer two different configurations. Both hardware and software have been upgraded to better meet users' actual needs. A 40HQ container can accommodate six 3015 units, facilitating less-than-container-load (LCL) shipping and significantly reducing freight costs.