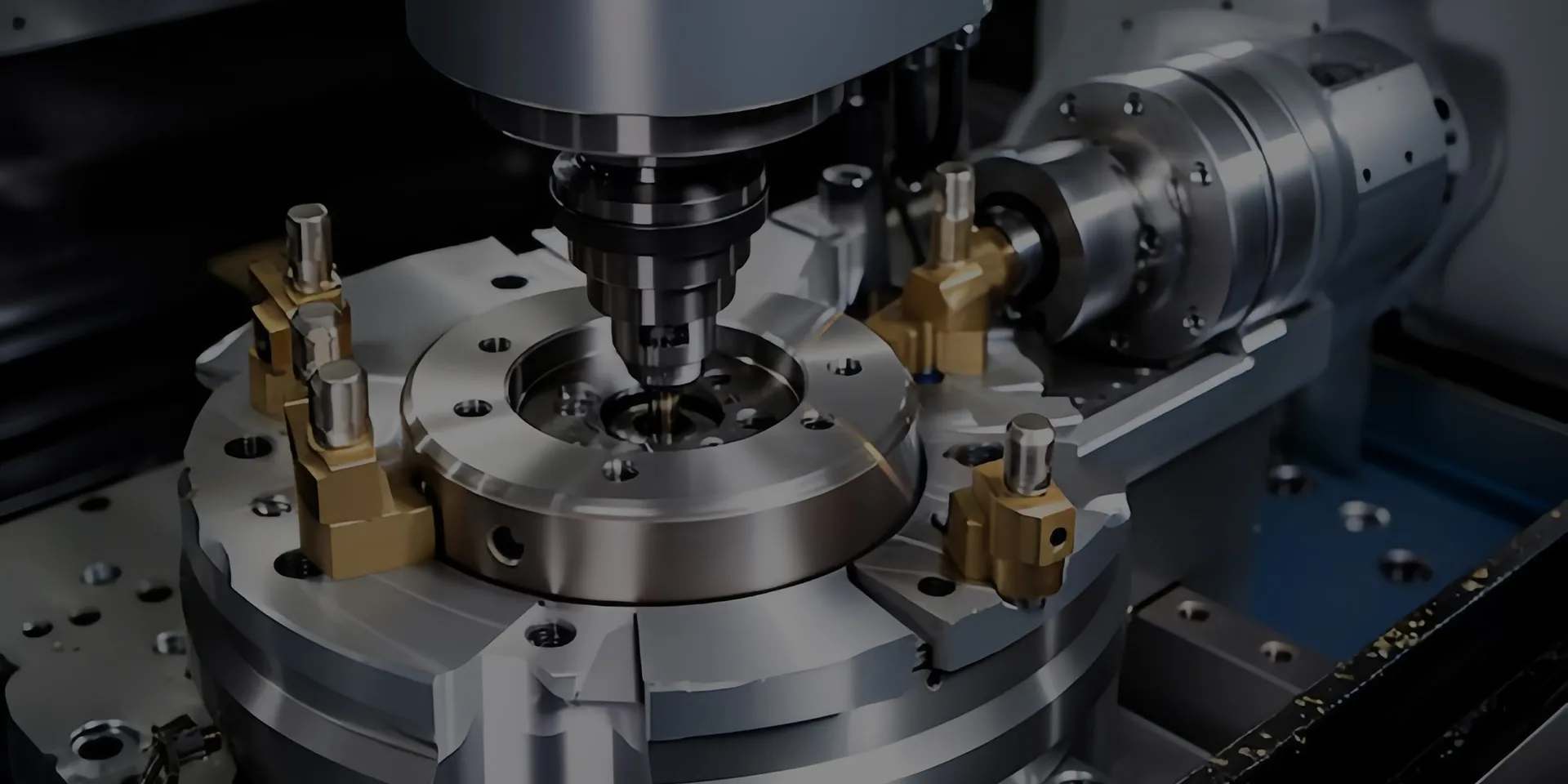

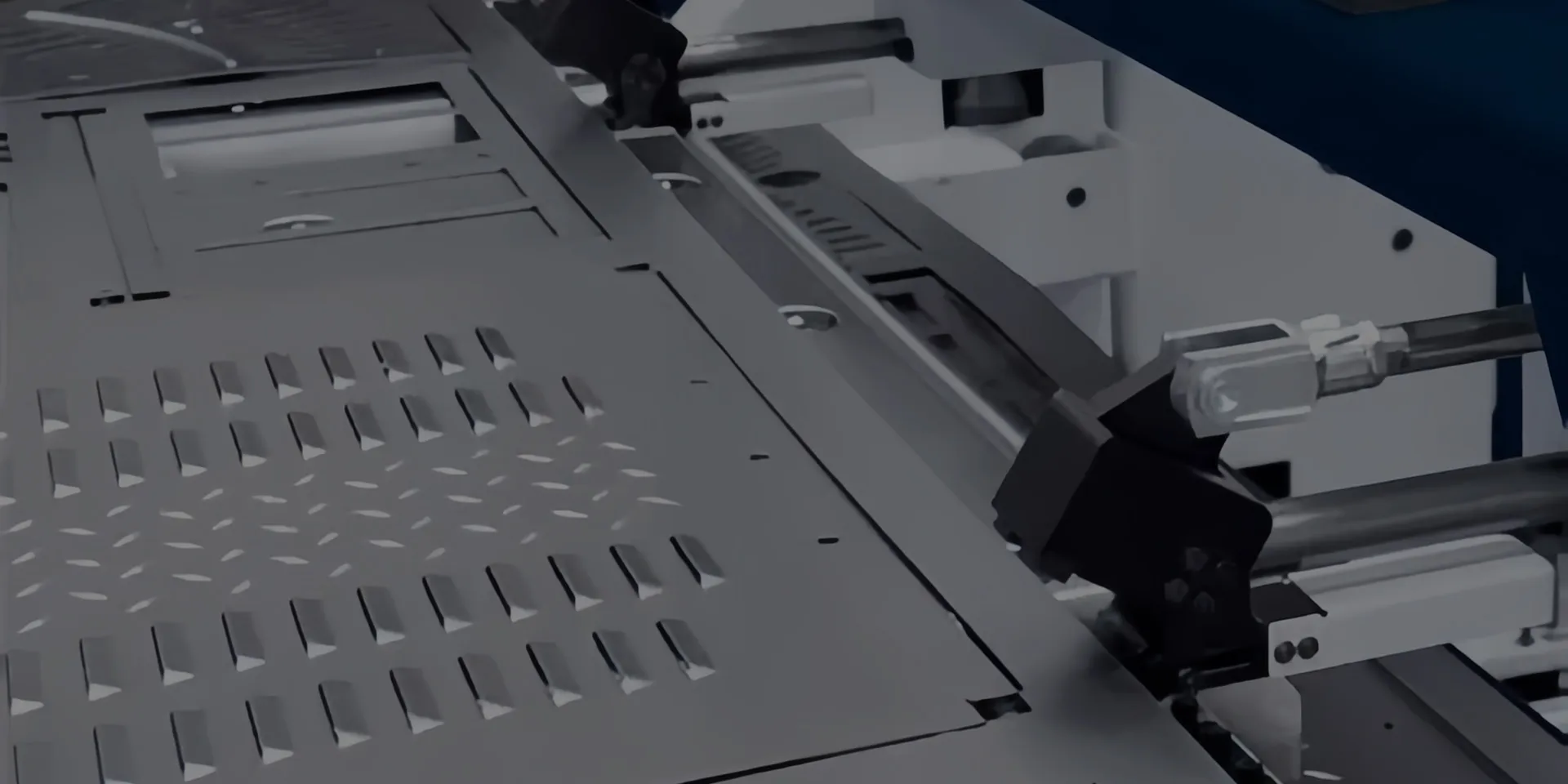

Modern Makinelerde Hassasiyet, Hız ve Uyarlanabilirliği Güçlendirmek

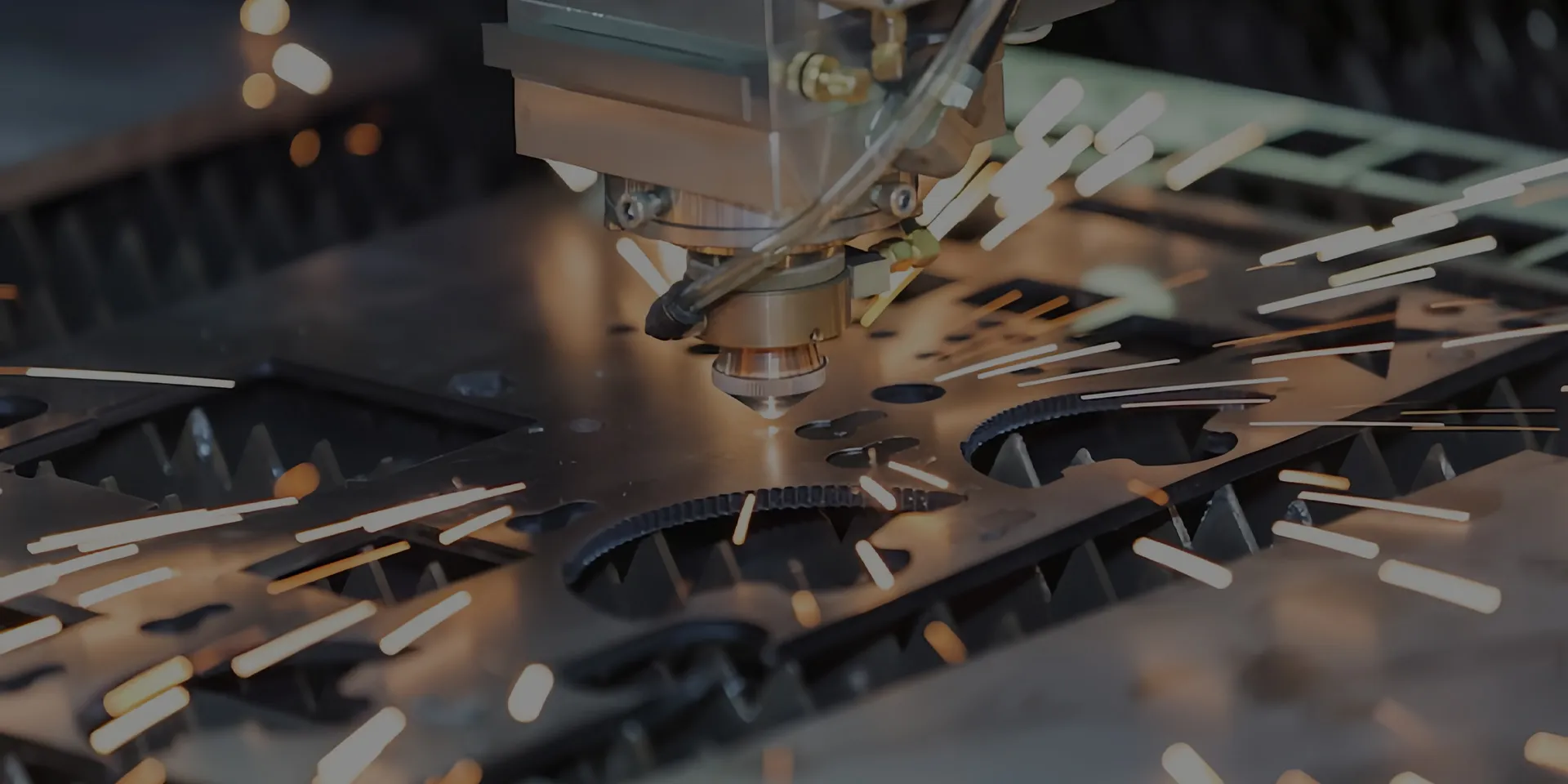

Otomasyon, sürdürülebilirlik ve çoklu süreç entegrasyonuna yönelik küresel talep, mekanik ekipman üretim ortamını yeniden şekillendiriyor. CNC sistemlerinden ve lazer tabanlı aletlerden robotik kollara ve akıllı montaj hatlarına kadar, üreticiler daha düşük enerji tüketimi ve ayak izi ile daha yüksek verimlilik arıyorlar. Hafif, yüksek mukavemetli malzemelere ve modüler tasarıma geçiş, aynı zamanda gelişen üretim hatları ve uluslararası kalite standartlarıyla uyumlu esnek ve hassas sac imalat yetenekleri gerektirir.