Tube Laser Cutting Machine: CNC Tube Lasers for High-Precision Tube Processing

A tube laser cutting machine is a CNC laser cutting machine designed to process round, squ…

learn more

Tube cutting becomes complex when precision drops, scrap increases, and manual handling slows production. These problems grow as tube sizes and designs diversify. A modern tube laser cutting machine solves them with CNC control, fiber laser power, and automated tube processing.

A tube laser cutting machine is a CNC laser cutting machine designed to process round, square, and shaped tubes with high speed and accuracy. Using fiber laser technology, tube lasers deliver precise cutting, bevel cutting, and automated handling for steel tubes used in modern manufacturing.

A tube laser cutting machine is a specialized laser cutting machine engineered for cutting metal tubes and profiles. Unlike flat sheet systems, tube lasers are designed for tube and pipe processing with controlled rotation, clamping, and synchronized movement.

At its core, the system uses a fiber laser to generate a focused laser beam that delivers precise cutting along the tube surface. Combined with CNC control, the laser tube cutting machine ensures stable cutting quality across different tube diameters and wall thicknesses.

For industries that rely on tubes and profiles, tube laser cutting machines provide efficiency, accuracy, and repeatability.

Tube lasers operate by rotating the tube while the cutting head moves along programmed cutting paths. The CNC system synchronizes rotation, linear motion, and laser output to achieve accurate results.

A modern laser tube cutting machine integrates:

This coordination allows the laser machine to perform straight cuts, holes, slots, and complex shapes in one continuous process. Compared to mechanical cutting, laser cutting technology significantly improves productivity and precision.

Fiber laser cutting has become the preferred solution for tube processing due to its efficiency and stability. A fiber laser tube cutting machine delivers higher cutting speed and lower operating costs than traditional systems.

Key advantages include:

Fiber laser tube lasers are especially effective for cutting steel, galvanized materials, and wide ranges of metal used in industrial production.

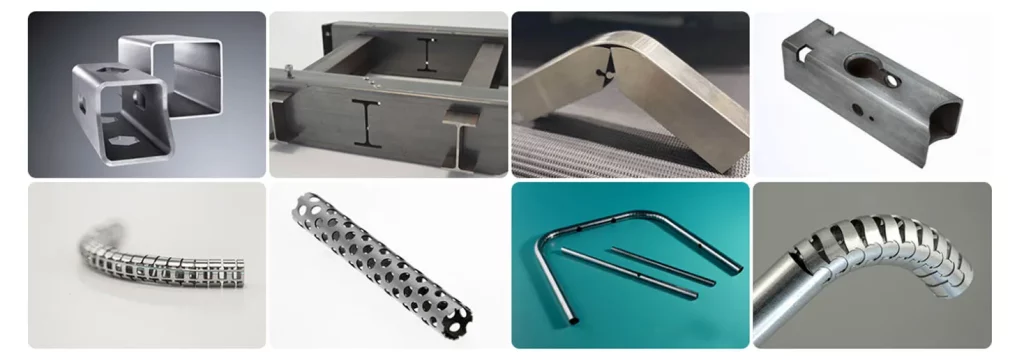

A CNC tube laser cutting machine supports different types of tubes and profiles, including:

With adjustable chuck systems, the machine can cut tubes with varying diameter and wall thicknesses. This flexibility allows manufacturers to process different tube sizes without changing cutting equipment.

Tube lasers are designed to cut a wide range of metal materials while maintaining stable cutting quality.

Modern tube lasers are capable of precision cutting and advanced bevel cutting. By tilting the cutting head or controlling the laser beam angle, the system can produce accurate bevels for welding preparation.

Bevel cutting is essential for:

With CNC laser control, the tube laser cutting machine delivers clean cuts and consistent bevel angles, reducing downstream welding work.

The chuck plays a critical role in tube processing. High-quality chuck systems ensure that the tube is firmly clamped and accurately centered during rotation.

Advanced tube lasers often use:

Cutting speed directly affects productivity in tube processing. A fiber laser tube cutting machine delivers high-speed cutting while maintaining cutting quality.

By optimizing laser power, cutting head control, and motion coordination, tube lasers achieve:

This combination allows manufacturers to meet tight delivery schedules without sacrificing accuracy.

Tube laser cutting machines are widely used across industries such as:

In industries such as automotive and aerospace, high-precision tube processing is critical for structural integrity and performance. Tube lasers deliver clean cuts and reliable results for these demanding sectors.

Tube cutting technology continues to evolve toward automation, higher precision, and intelligent control. Tube lasers enable efficient and precise production of complex tube components.

A modern tube laser cutting machine supports:

For manufacturers seeking competitive advantages, tube laser cutting technology is an essential investment.

What is a tube laser cutting machine?

It is a CNC laser cutting machine designed for cutting metal tubes and profiles with high precision.

Can tube lasers perform bevel cutting?

Yes. Modern tube lasers support bevel cutting for welding-ready tube components.

What materials can tube laser cutting machines process?

They are capable of cutting steel, galvanized metal, and a wide range of metal tubes.

Is automation important in tube laser cutting?

Automation improves productivity, safety, and consistency in tube processing.

What industries use tube laser cutting machines?

Industries such as automotive, aerospace, furniture, and equipment manufacturing widely use tube lasers.

A tube laser cutting machine is a CNC laser cutting machine designed to process round, squ…

learn more

An industrial laser cutting machine uses a high-powered laser system to cut large-format m…

learn more

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 15589913375. Or call +86 15589913375 directly.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.

Ultimate dynamics and efficiency

Durability and reliability

Upgraded precision and accuracy

Intelligent & ease of use

Safety & healthy

Versatile automation