Performance based on robustness and, above all, reliability.

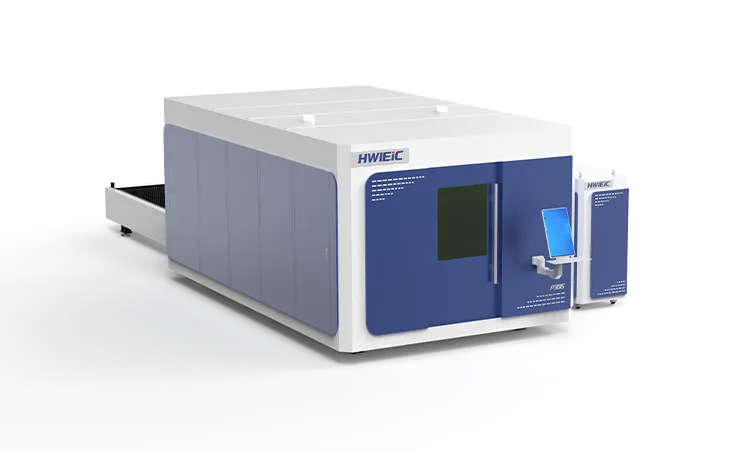

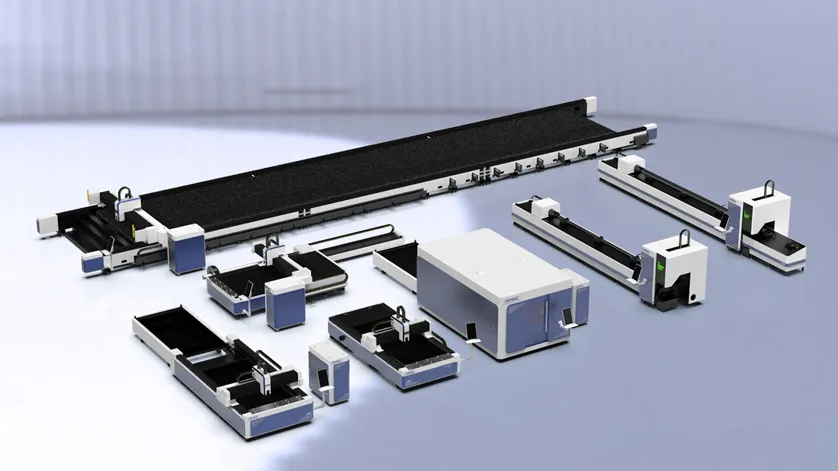

Explore HWlEiC’s P-Series of high-power laser cutting machines for a variety of metal cutting needs, offering high-precision and high-efficiency cutting solutions.

Classic single plane laser cutting machine - Features & Configuration

After technical and functional upgrades, this model boasts rich functions and stable performance, providing customers with fast and high-quality cutting of medium-thin sheets.

Superior performance

Performance Benefits

This machine works stably and has good dynamic performance, so as to serve users for a long time at ultra-high power.

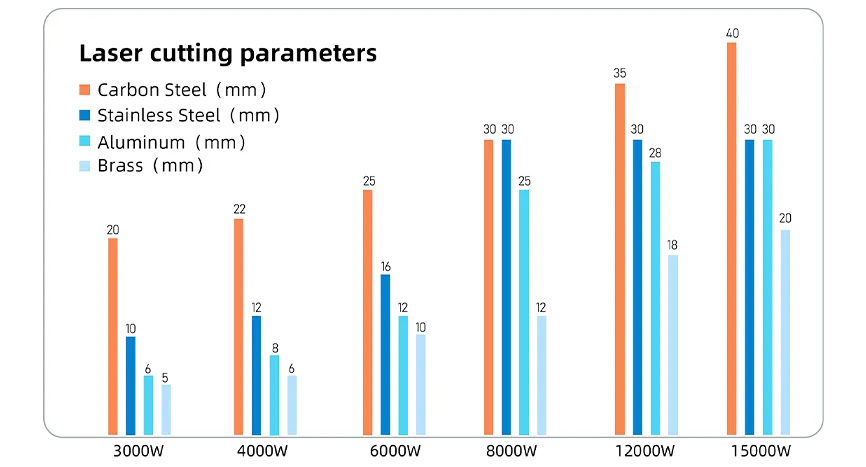

Cut medium-thick plate

6-90mm stainless steel, 5-80mm carbon steel, 5-60mm AL alloy, 5-30mm brass

Multiply cutting speed

About 3-5 times faster than other plate laser cutters

High degree of intelligence

Top configurations in both software and hardware, in particular some unique functions, so its oversea market reception is rising steadily

Basic single plane laser cutting machine With Robust, Safe, Essential

Includes Following Features And Configuration

-

Compact design with integrated power, control, and cooling system, perfectly fits mold workshops with limited space.

-

Rigid welded frame with stress relief treatment ensures consistent cutting precision during long mold-making processes.

-

Real-time piercing adjustment adapts to varied mold base thicknesses, avoiding manual recalibration.

-

Multi-axis intelligent control supports intricate contour paths essential for complex mold cavity shaping.

-

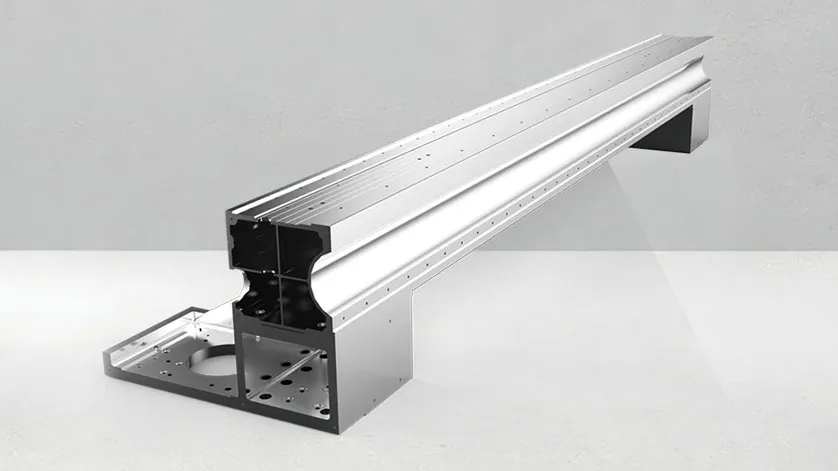

High-strength aluminum beam delivers smooth movement and high-speed cutting on tool steel and hard alloys.

-

Enclosed cabinet separates strong and weak currents, reducing EMI risks when processing high-precision components.

-

One-click edge alignment improves accuracy in engraving mold numbers and fine structure outlines.

-

High-power laser source delivers smooth, burr-free cuts in thick steel inserts for injection molds.

-

Smart anti-collision sensors protect expensive mold blanks during high-speed operation.

-

Modular worktable allows fast replacement of clamping fixtures for different mold components.

-

Smoke-free dual-zone ventilation system maintains visibility when cutting acrylic or transparent mold covers.

-

Minimal heat-affected zone reduces post-machining and protects dimensional tolerance on precision parts.

-

CNC system with 21.5” touchscreen enables easy programming of mold part libraries and layout optimization.

-

Supports batch nesting of mold plates to maximize material use and reduce waste.

-

Supports batch nesting of mold plates to maximize material use and reduce waste.

Flexibility and efficiency

Its minimalist structure combines its main body, electrical cabinet, control system, air compressor, laser generator, and water chiller into one, so as to reduce space costs and improve workshop utilization.

Why hwieic ?

- Ultimate dynamics and efficiency

- Durability and reliability

- Upgraded precision and accuracy

- Intelligent & ease of use

- Safety & healthy

- Versatile automation

Product Performance

This machine works stably and has good dynamic performance, so as to serve users for a long time at ultra-high power.

| MODEL | P12025 | P10025 | P8025 | P6025 | P4020 | P3015 |

| Processing format | 12000mm*2500mm | 10000mm*2500mm | 8000mm*2500mm | 6000mm*2500mm | 4000mm*2000mm | 3000mm*1500mm |

| acceleration | 1.0G | 1.0G | 1.5G | 1.5G | 1.5G | 1.5G |

| Overall weight | 25000kg | 20000kg | 16000kg | 12000kg | 8000kg | 5500kg |

| laser head | 6KW below:RAYTOOLS 10KW and above:PORAD |

6KW below:RAYTOOLS 6KW and above:Germany Precitec |

RAYTOOLS | |||

| Laser source | MAX/Raycus/IPG | |||||

Product Performance

The reliable choice for lower costs with easy operation

- Laser power: 3-50[kW]

- Plate size: 3000*1500-12000*2500 [mm]

- Max no-load speed: 200 [m/min]

- Maximum Load: 18860 [kg]

Tried-and-tested design

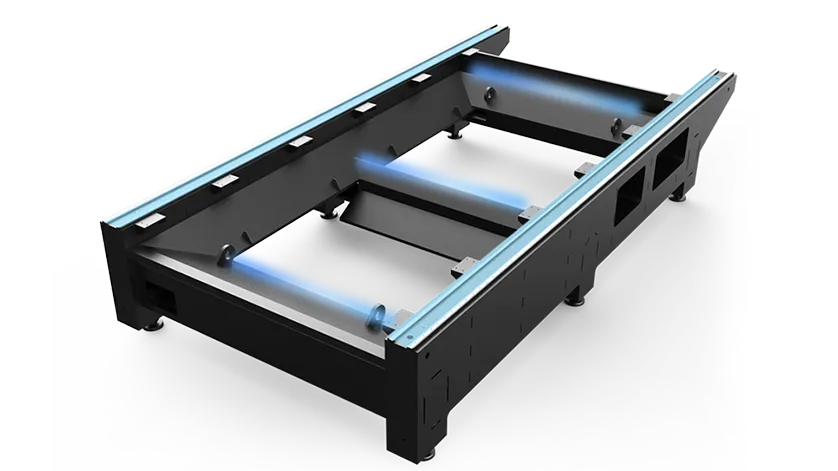

Double exchange platforms available to save waiting time for loading & unloading

Adopt hollow machine tool and graphite plates as fire prevention

Aviation-grade AL beam at high strength, enabling its cutting into various shapes at high speed

Fully-enclosed structure, with flip-in air door and dust curtain for safety and environmental protection

Efficient drive system

We use integrated electronic components & precision guide rail and racks (100% match) to enable high acceleration (2.8G) and positioning accuracy (±0.05mm).

High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like 600° high annealing

Visual collision avoidance

All-round monitoring without dead zone, making cutting safer

Control System Benefits

We employ intelligent bus-based CNC system equipped with 21.5-inch touch screen. It is easy to install and debug, featuring rapid and fast data transmission, low failure rate and easy maintenance.

Lightning-fast piercing

Fast to pierce through thick plates at high quality

High quality results in all sheet thickness

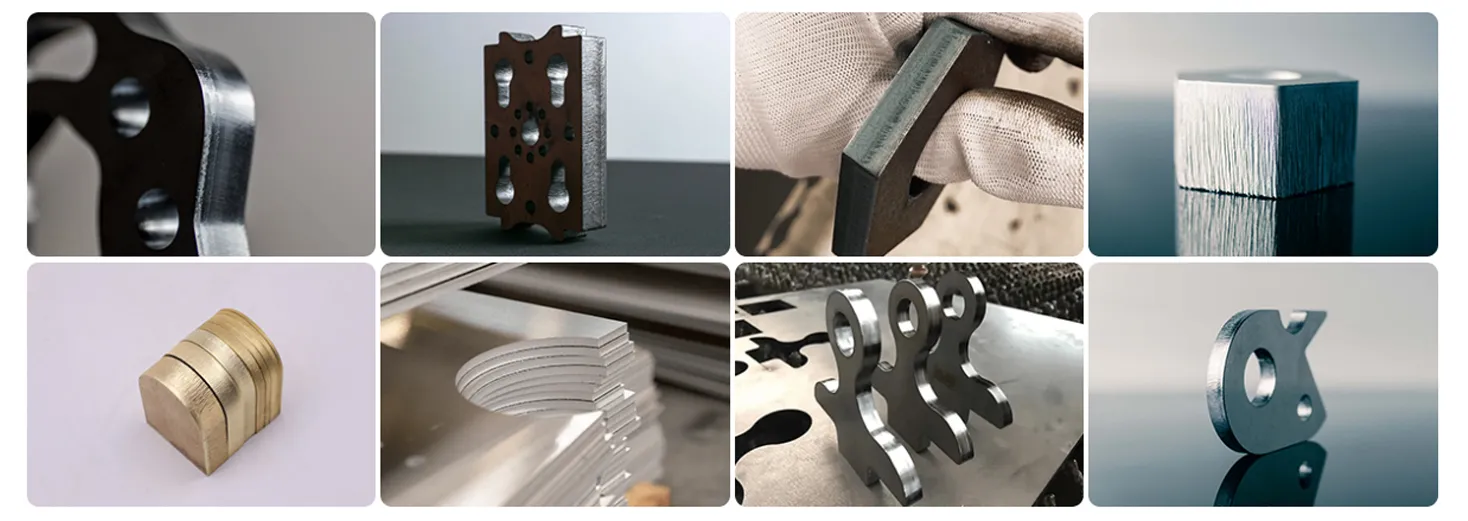

As one of the classic models, the P series fiber laser cutting machine is mainly used for metal materials such as stainless steel, carbon steel, galvanized sheet, brass, aluminum, and various alloy plates

Customer Visit

The HWlEiC A series provides cost-efficiency and high performance for various industries looking to upgrade metal processing methods and improve competitiveness.

Request A Quote

Please fill out the form below to request a quote,catalog,or technical consultation.Our team will get back to you within 24 hours.

Get a Quote

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 ******,. Or call +86 ****** directly.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.

Products

POWER TOOLS

Ultimate dynamics and efficiency

Durability and reliability

Upgraded precision and accuracy

Intelligent & ease of use

Safety & healthy

Versatile automation