La Serie De F

Flagship Product sheet fiber laser metal cutting machine

Superior Performance F Series Delivers Top-Notch Quality, Allowingfor Faster, Smoother, And More Precise Lasercutting. An ideal Choice To Meet Your Highstandards.

Sin deformación de corte de acero inoxidable, acero al carbono, cobre, placa, placa de aluminio, etc. Alta velocidad de corte, de alta precisión, continua el corte por un largo tiempo. Perforación del agujero, de productos, de corte de gráficos, etc. Buena calidad del haz, sin rebabas, sin escoria, ni negro, borde, sin necesidad de procesamiento secundario más estrecho de corte, costura, mínimo de la zona afectada por el calor, local mínimo la deformación de la pieza de trabajo.

Después de la técnica y funcional de las actualizaciones, este modelo cuenta con ricos funciones y un rendimiento estable, proporcionando a los clientes con alta velocidad y calidad de corte de las medianas-láminas delgadas.

Rendimiento Superior

Después de la técnica y funcional de las actualizaciones, este modelo cuenta con ricos funciones y un rendimiento estable, proporcionando a los clientes con alta velocidad y calidad de corte de las medianas-láminas delgadas.

At high power, its cutting section is smooth with no burr or adhering slag. Basically no need for secondary polishing.

Mantenga la máquina herramienta indeformable y continuo a alta temperatura, incluso después de largo tiempo de uso debido de ir a través de los 7 procesos estándar igual a 600° alta recocido

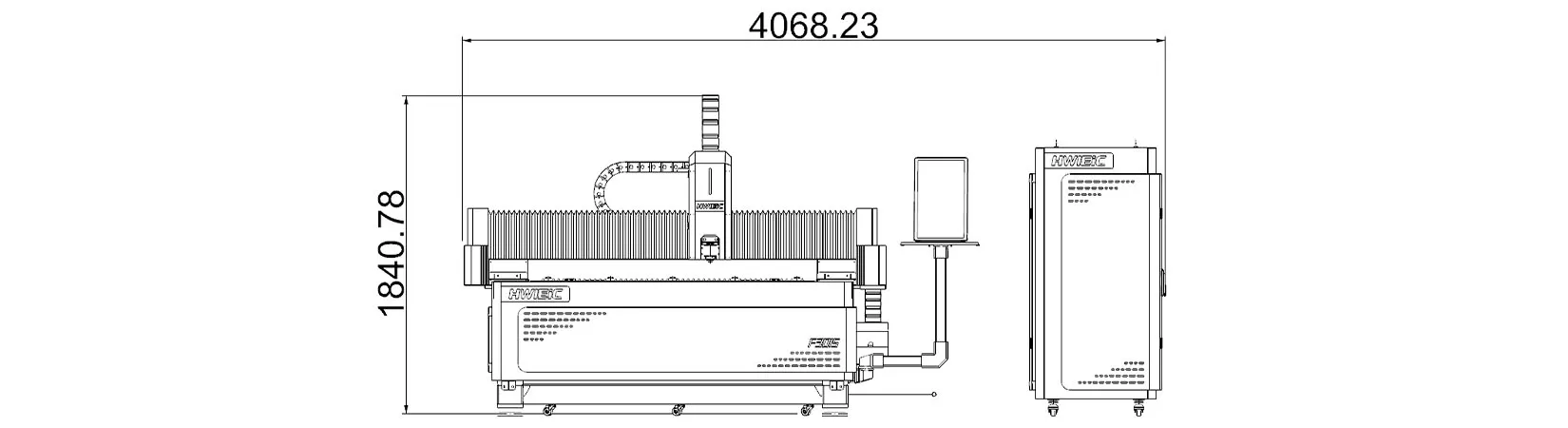

A 40HQ container can hold 8 sets of 3015F, which provides a new option for bulk ordering customers and sharply reduces shipping costs.

Compact design integrates power cabinet, control system, laser, and chiller into a 12m² footprint.

Open-body structure offers full visibility and effortless loading from three sides.

Integrated electric cabinet with separate strong/weak current reduces interference and boosts lifespan.

Reinforced welded bed undergoes stress relief and aging treatment for lasting rigidity.

Modular firebrick-protected tool bits are easy to replace and safer during cutting.

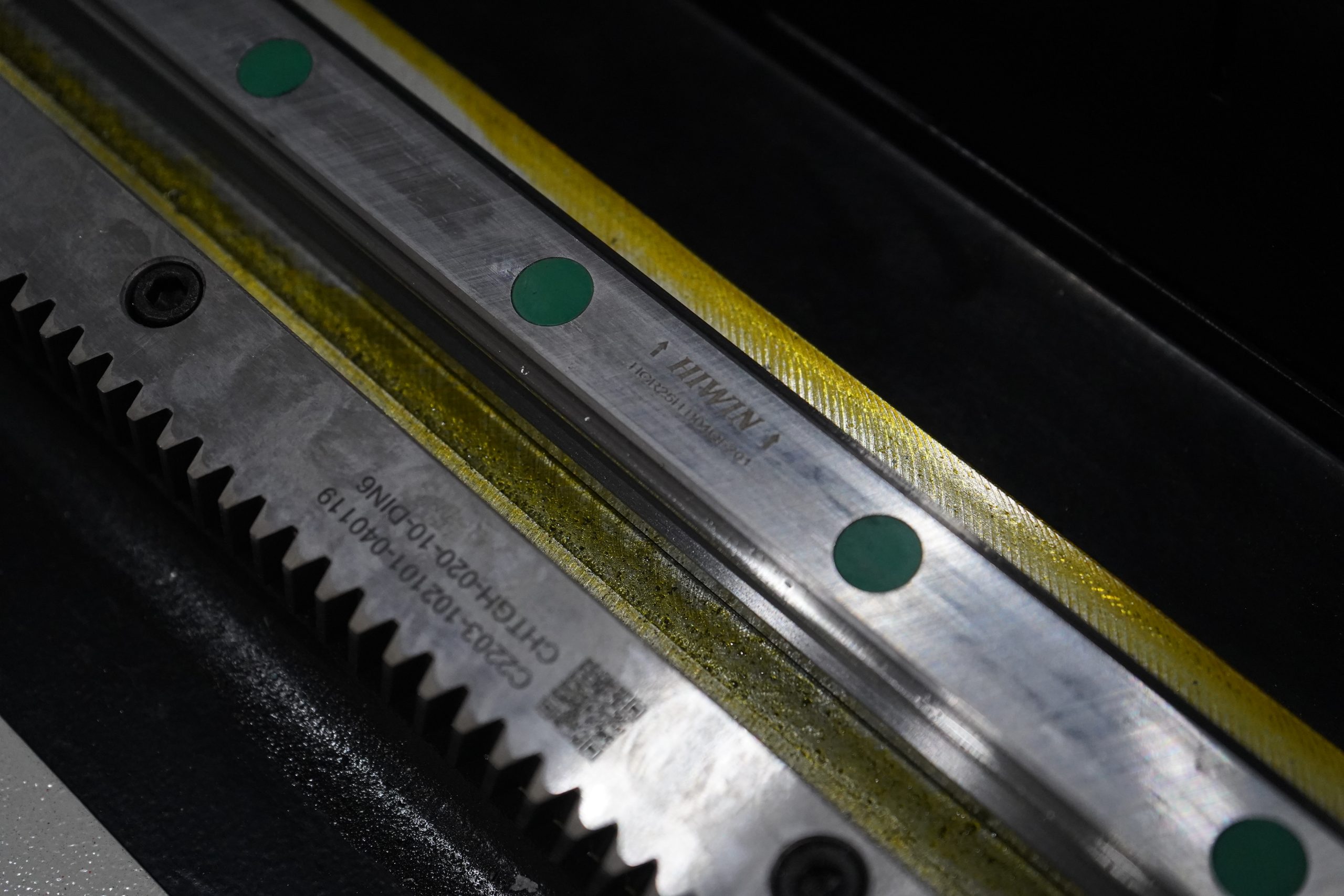

High-strength aluminum alloy beam ensures faster movement and cutting accuracy.

Dual ventilation ducts and suction-blow design create smoke-free workshops.

Intelligent bus CNC with 21.5” touchscreen offers fast, stable data and easy setup.

One-click disc centering improves part positioning and cutting accuracy.

Multi-stage piercing adapts in real-time to different sheet thicknesses.

Smart obstacle avoidance prevents collisions and protects workpieces.

Delivers clean, burr-free, polish-free cuts even on high-power thick sheet jobs.

A 40HQ container fits 8 sets of 3015F, cutting bulk shipping costs sharply.

Open-style design supports efficient material handling and better production visibility.

Designed for precision, speed, and minimal post-processing in medium-thin sheet cutting.

Su estructura minimalista, combina su cuerpo principal, armario eléctrico, sistema de control, compresor de aire, generador de láser, y enfriador de agua en una sola, así como a reducir los costes de espacio y mejorar el taller de utilización.

Después de la técnica y funcional de las actualizaciones, este modelo cuenta con ricos funciones y un rendimiento estable, proporcionando a los clientes con alta velocidad y calidad de corte de las medianas-láminas delgadas.

| MODELO | F6025 | F6015 | F4020 | F3015 |

| Working area | 6000mm*2500mm | 6000mm*1500mm | 4000mm*2000mm | 3000mm*1500mm |

| Laser output power | 1.5-50KW | |||

| Positioning accuracy | ±0.01mm/m | |||

| Repositioning accuracy | ±0.01mm | |||

| Max. linkage speed | 200m/min | |||

La opción confiable para la reducción de los costes con la operación fácil

Su estructura minimalista, combina su cuerpo principal, armario eléctrico, sistema de control, compresor de aire, generador de láser, y enfriador de agua en una sola, así como a reducir los costes de espacio y mejorar el taller de utilización.

* Open-style structure with no top cover, giving a sweeping view of whole cutting process. There are eye wheels on left and front of machine tool bed, to make loading and unloading from the left, right, and rear side easier.

* Compact in structure with single platform and built-in laser generator, which occupies a small footprint (only 12m²).

* Integrated power distribution cabinet, with separating strong and weak current to reduce electrical interference and enhance working stability and lifespan.

Customizable Laser Power, Cutting Heads, Controls & Intelligent Auxiliaries

Con peso ligero, de baja inercia y excelente rendimiento dinámico, el haz puede traer de alta precisión, velocidad sin carga y la eficiencia de trabajo.

Empleamos inteligente basada en bus del sistema del CNC equipado con pantalla de 21,5 pulgadas de pantalla táctil. Es fácil de instalar y depurar, gracias a su rápido y transmisión de datos rápida, baja tasa de fracaso y de fácil mantenimiento.

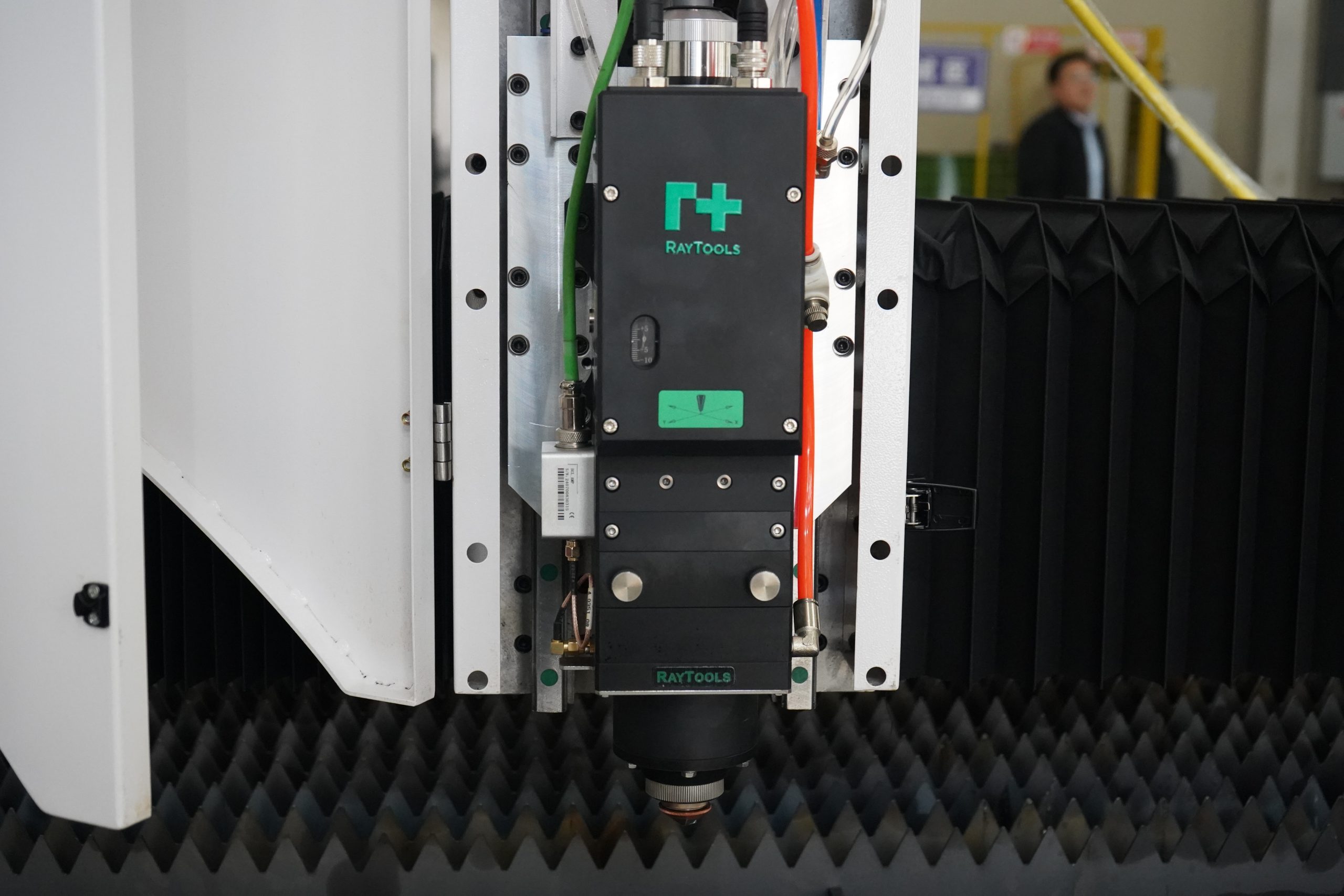

Pequeño en tamaño y luz en peso, con todas las ópticas y de la refrigeración por agua de diseño

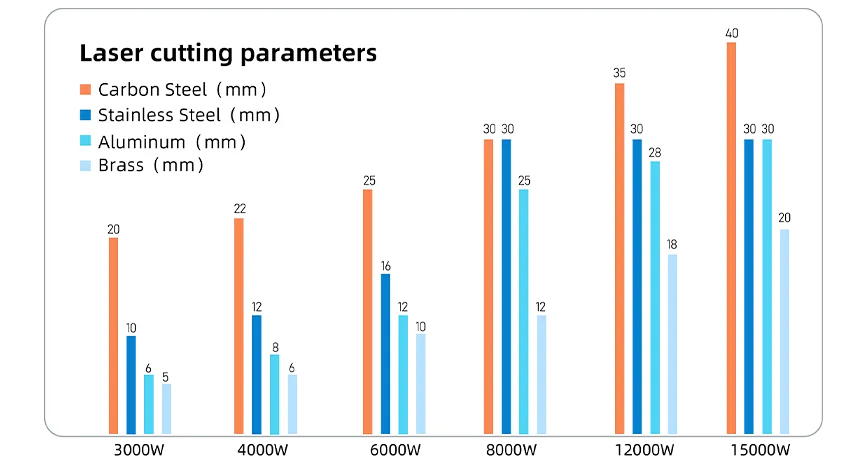

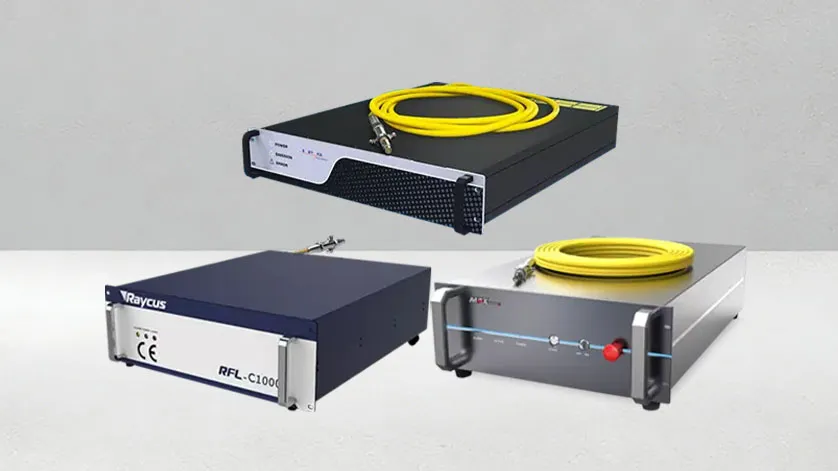

Multiple types of high-quality laser sources available with full power coverage from 1500W to 50000W, tailor-made processing solutions on demand

Alta estabilidad de la fuente de láser con el uniforme de la energía de salida, el equilibrio de la eficiencia de corte y procesamiento de precisión

Gama completa de potencia adaptada para el procesamiento industrial de diversos materiales, altamente confiable núcleo de poder de los diferentes escenarios

Como uno de los modelos clásicos, la serie a de fibra de corte por láser de la máquina se utiliza principalmente para materiales metálicos, tales como acero inoxidable, acero al carbono, galvanizado, latón, aluminio, y varias placas de aleación de

The HWlEiC F series provides cost-efficiency and high performance for various industries looking to upgrade metal processing methods and improve competitiveness.

Por favor, rellene el siguiente formulario para solicitar un presupuesto,catálogo,o en la consulta técnica.Nuestro equipo se pondrá en contacto con usted dentro de 24 horas.

Le responderemos dentro de 24 horas. Si por caso urgente, por favor agregar WhatsApp/WeChat: +86 15589913375. O llame al +86 15589913375 directamente.

*Hemos de respetar su confidencialidad y toda la información están protegidos.

Sólo utilizaremos su información para responder a su consulta y nunca envía correos electrónicos no solicitados o mensajes promocionales.

Final de la dinámica y la eficiencia

La durabilidad y fiabilidad

Actualizado precisión y exactitud

Inteligente y fácil de utilizar

La seguridad y salud de la

Versátil automatización