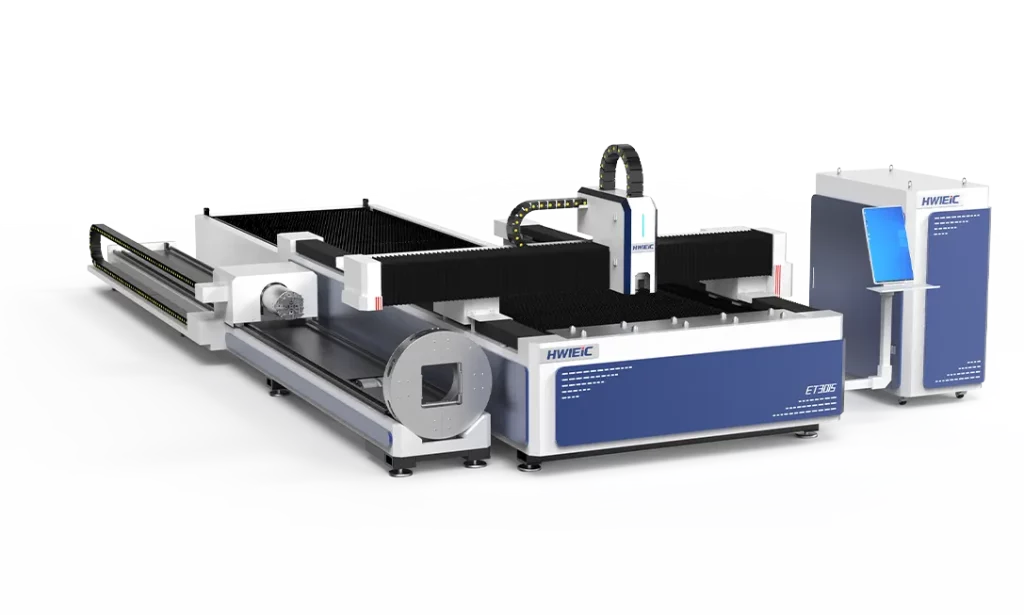

Tube Laser Cutting Machine: CNC Tube Lasers for High-Precision Tube Processing

A tube laser cutting machine is a CNC laser cutting machine designed to process round, squ…

aprender más

Tubo de procesamiento es cada vez más complejo, mientras que las tolerancias de seguir recibiendo más. Tubo tradicionales máquinas de corte de lucha con la velocidad, la precisión y la consistencia. Un láser de tubo de la máquina de corte resuelve estos problemas mediante la combinación de automatización, alta velocidad de corte, y un control preciso en una inteligente solución de corte.

Un laser pipe cutting machine, also known as a tube laser cutting machine, uses a focused laser beam and CNC control to cut metal tubes and profiles with high precision and efficiency. Compared with traditional cutting machines, tube laser cutting delivers cleaner cuts, faster processing, and greater flexibility for modern metal fabrication and tube processing industries.

Un laser pipe cutting machine is a specialized form of laser cutting machine designed for tube cutting and pipe cutting applications. Unlike flat-sheet cutting machines, it uses a rotating chuck system to hold tubes and profiles while the laser beam performs precise cutting along a programmed cutting path.

At its core, the system combines la tecnología láser, CNC control, and an advanced cutting head. The tube is held firmly at the concentric point of the chuck, ensuring accurate cutting even at high cutting speed. This structure allows the laser machine to cut round tubes, square tube, rectangular profiles, and different types of tubes with consistent cut quality.

For manufacturers handling tubes and profiles in volume, tube laser cutting machines provide a reliable and repeatable cutting process that traditional processing machines cannot match.

Traditional tube cutting machines rely on mechanical saws, drilling, or plasma systems. These methods often struggle with burrs, secondary processing, and limited flexibility. Laser pipe cutting offers a cleaner, faster alternative.

With tube laser cutting, cutting machines deliver:

A fiber laser tube cutting machine can cut mild steel, carbon steel, and various metal materials without tool wear. This makes tube laser cutting machines widely used in metal fabrication where accuracy and repeatability are critical.

In modern tube processing, fiber laser technology dominates tube laser cutting. Fiber laser machines offer higher energy efficiency, stable laser beam quality, and excellent performance when cutting metal pipes.

Compared with older laser types, fiber laser cutting provides:

While CO₂ systems still exist in specific use cases, most industrial tube laser cutting machines today rely on fiber laser cutting for cutting metal efficiently and accurately.

A modern cnc laser tube cutting system transforms tube cutting into a fully automated process. CNC control allows precise positioning, rotation, and synchronization between the chuck and cutting head.

Automation features often include:

With automatic loading and unloading, manufacturers reduce manual handling and improve cutting efficiency. This level of automation is especially valuable for large and medium-sized manufacturing enterprises seeking stable, long-term production.

Un tube laser cutter is capable of cutting a wide range of metal tubes and profiles, including:

Thanks to advanced chuck design, the tube is held securely even when cutting at high cutting speed. This stability ensures accurate cutting across various metal fabrication applications.

For industries working with tubes and profiles daily, tube laser cutting machines offer unmatched flexibility in the manufacturing process.

Precision is one of the biggest advantages of laser tube cutting technology. A high-quality laser tube cutting machine delivers high precision and consistent cut quality across long production runs.

Advanced systems support:

By controlling laser power and cutting speed, the laser machine achieves clean cuts with smooth edges. This reduces downstream welding and assembly time, improving overall productivity.

One key reason manufacturers invest in tube laser cutting machines is productivity. A fiber laser tube cutting machine allows faster cutting while maintaining high precision.

Compared with traditional methods, tube laser cutting:

High cutting speed combined with stable CNC control means one laser pipe cutting machine can replace multiple traditional tube cutting machines.

Tube laser cutting machines are no longer standalone equipment. They are core processing machines within intelligent manufacturing systems.

By integrating CNC fiber laser tube cutting with automation and data systems, manufacturers achieve:

This is why tube laser cutting technology plays a critical role in the world of laser tube cutting and modern metal fabrication.

Un laser pipe cutting machine is no longer optional for manufacturers focused on tube processing and metal fabrication. By combining fiber laser technology, CNC control, and automation, tube laser cutting machines deliver speed, precision, and long-term reliability.

For manufacturers seeking intelligent, secure, and scalable cutting solutions, tube laser cutting is a proven path toward higher productivity and sustainable competitive advantage.

A tube laser cutting machine is a CNC laser cutting machine designed to process round, squ…

aprender más

An industrial laser cutting machine uses a high-powered laser system to cut large-format m…

aprender más

Le responderemos dentro de 24 horas. Si por caso urgente, por favor agregar WhatsApp/WeChat: +86 15589913375. O llame al +86 15589913375 directamente.

*Hemos de respetar su confidencialidad y toda la información están protegidos.

Sólo utilizaremos su información para responder a su consulta y nunca envía correos electrónicos no solicitados o mensajes promocionales.

Final de la dinámica y la eficiencia

La durabilidad y fiabilidad

Actualizado precisión y exactitud

Inteligente y fácil de utilizar

La seguridad y salud de la

Versátil automatización