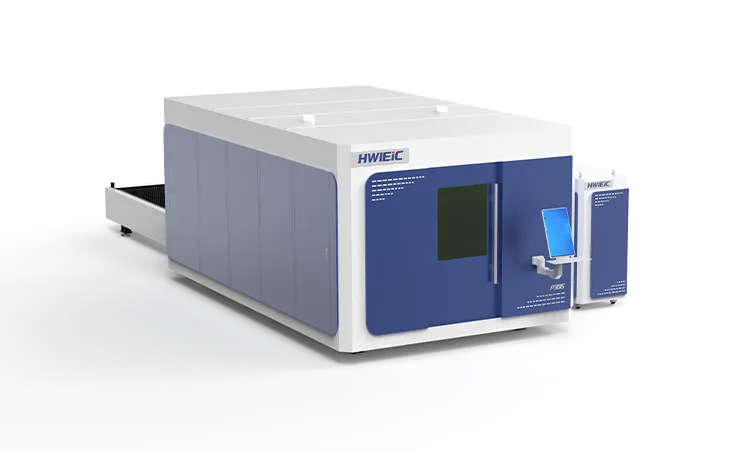

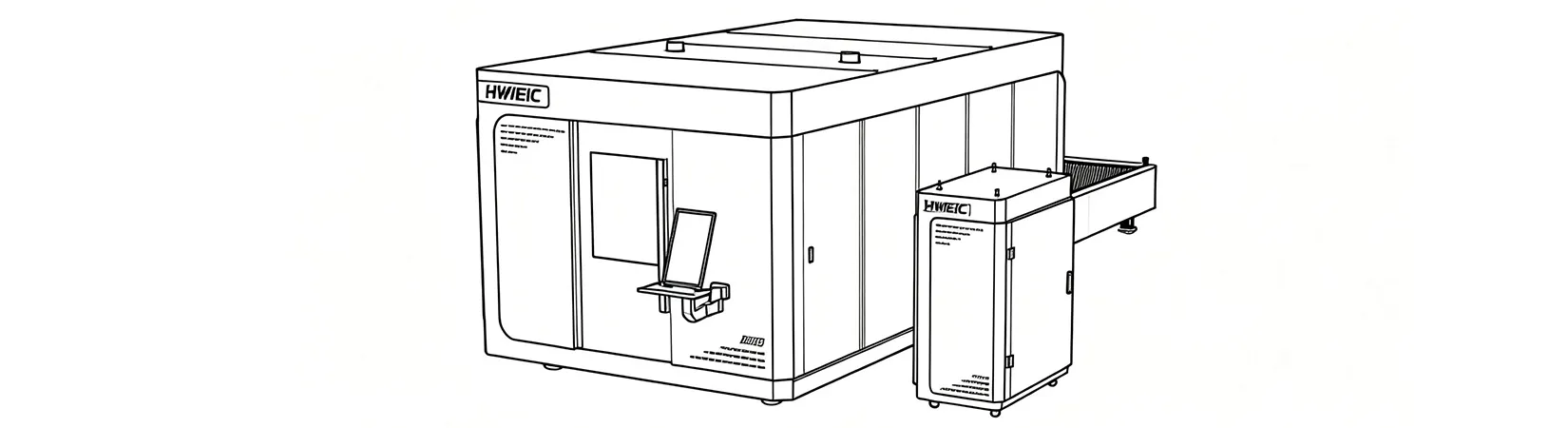

Explorar HWlEiC de la Serie P de alta potencia del láser, máquinas de corte para una variedad de corte de metal necesidades, que ofrece una alta precisión y alta eficiencia de corte de soluciones.

Después de la técnica y funcional de las actualizaciones, este modelo cuenta con ricos funciones y un rendimiento estable, proporcionando a los clientes con alta velocidad y calidad de corte de las medianas-láminas delgadas.

Rendimiento Superior

Esta máquina funciona de manera estable y tiene un buen rendimiento dinámico, así como para servir a los usuarios por un largo tiempo en ultra-alta energía.

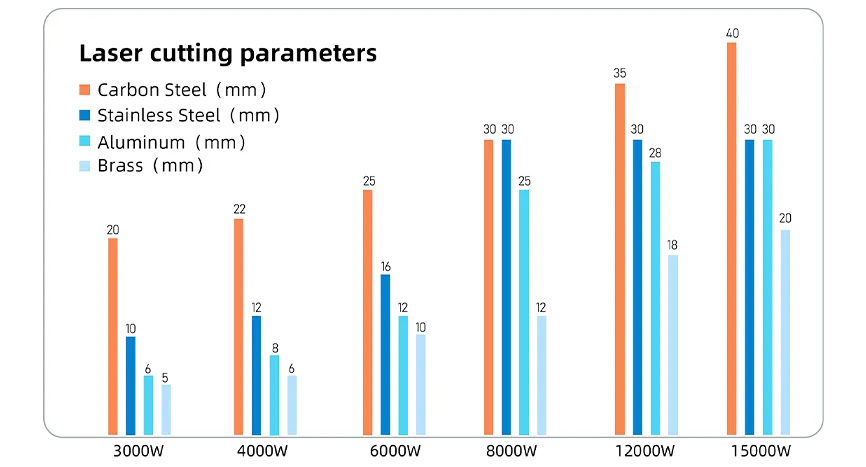

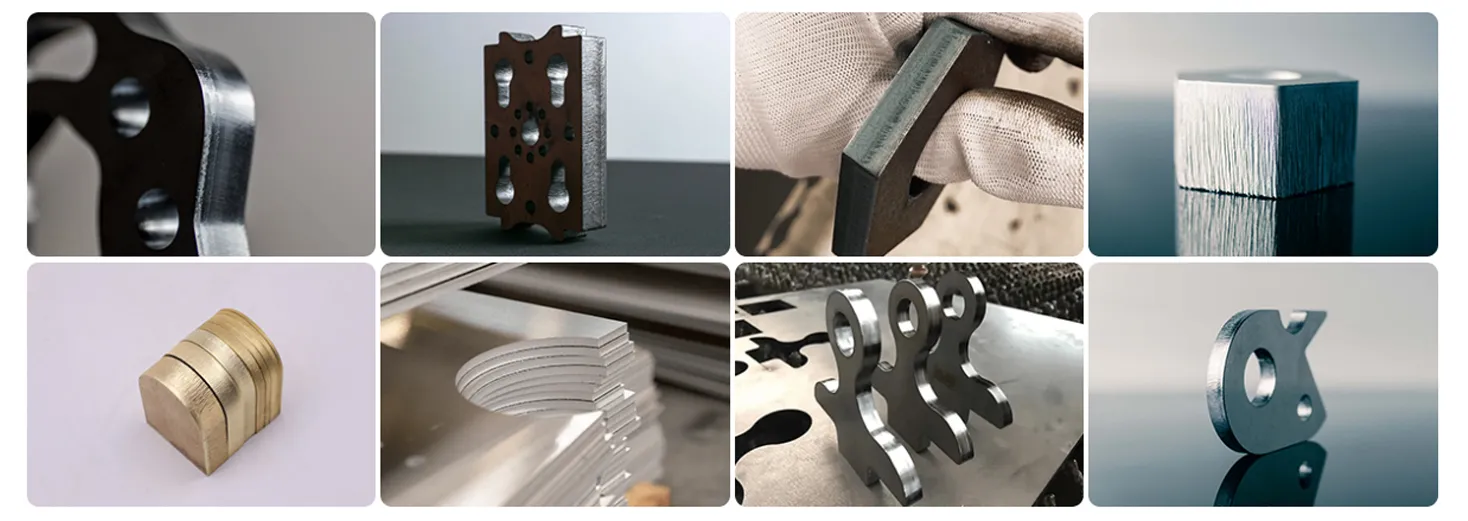

6-90 mm de acero inoxidable, 5-80 mm de acero al carbono, 5-60 mm de AL aleación, 5-30 mm de latón

Acerca de 3-5 veces más rápido que otros de la placa de cortadoras láser

Configuraciones de software y hardware, en particular algunas funciones únicas, por lo que su mercado de ultramar recepción está aumentando de manera constante

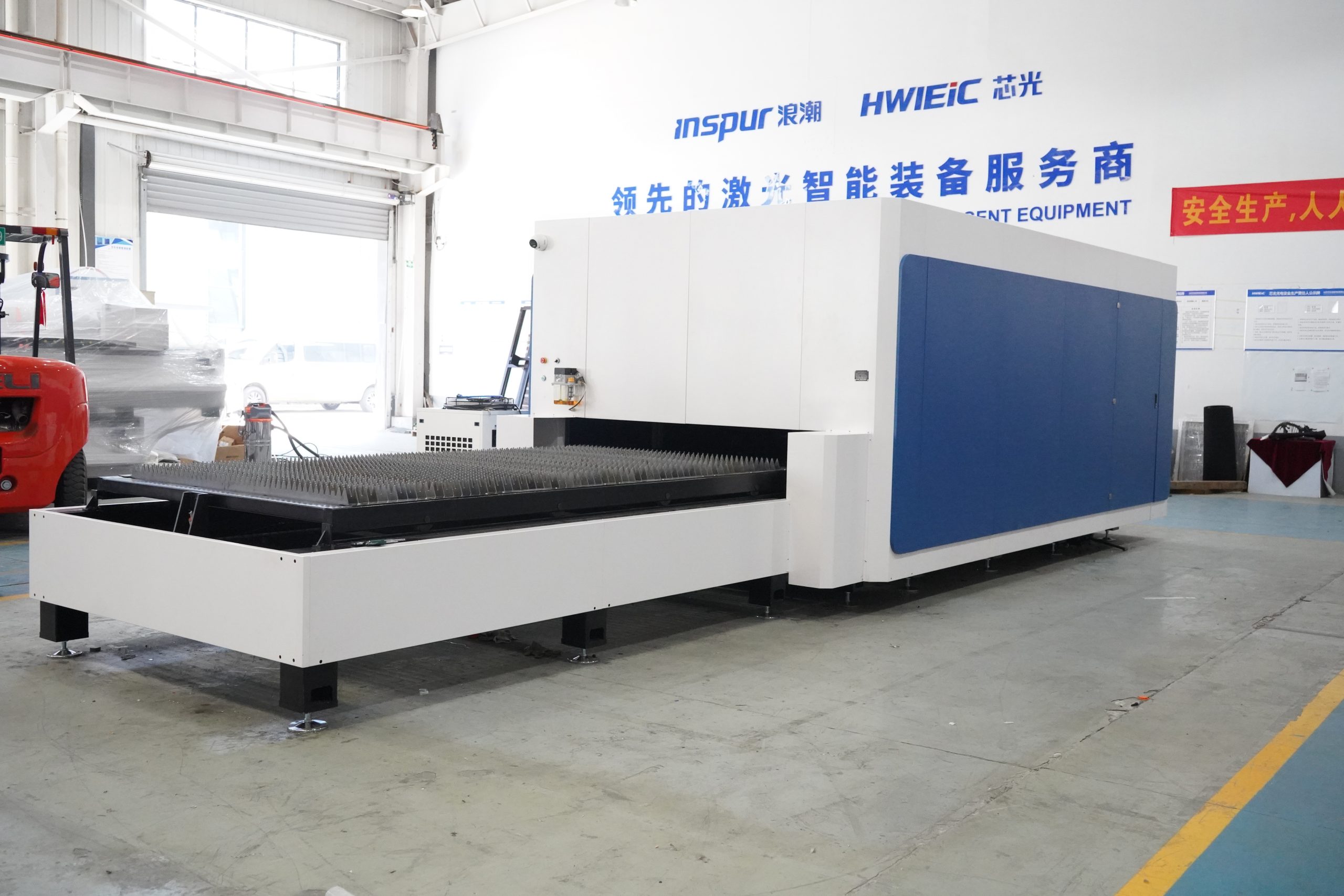

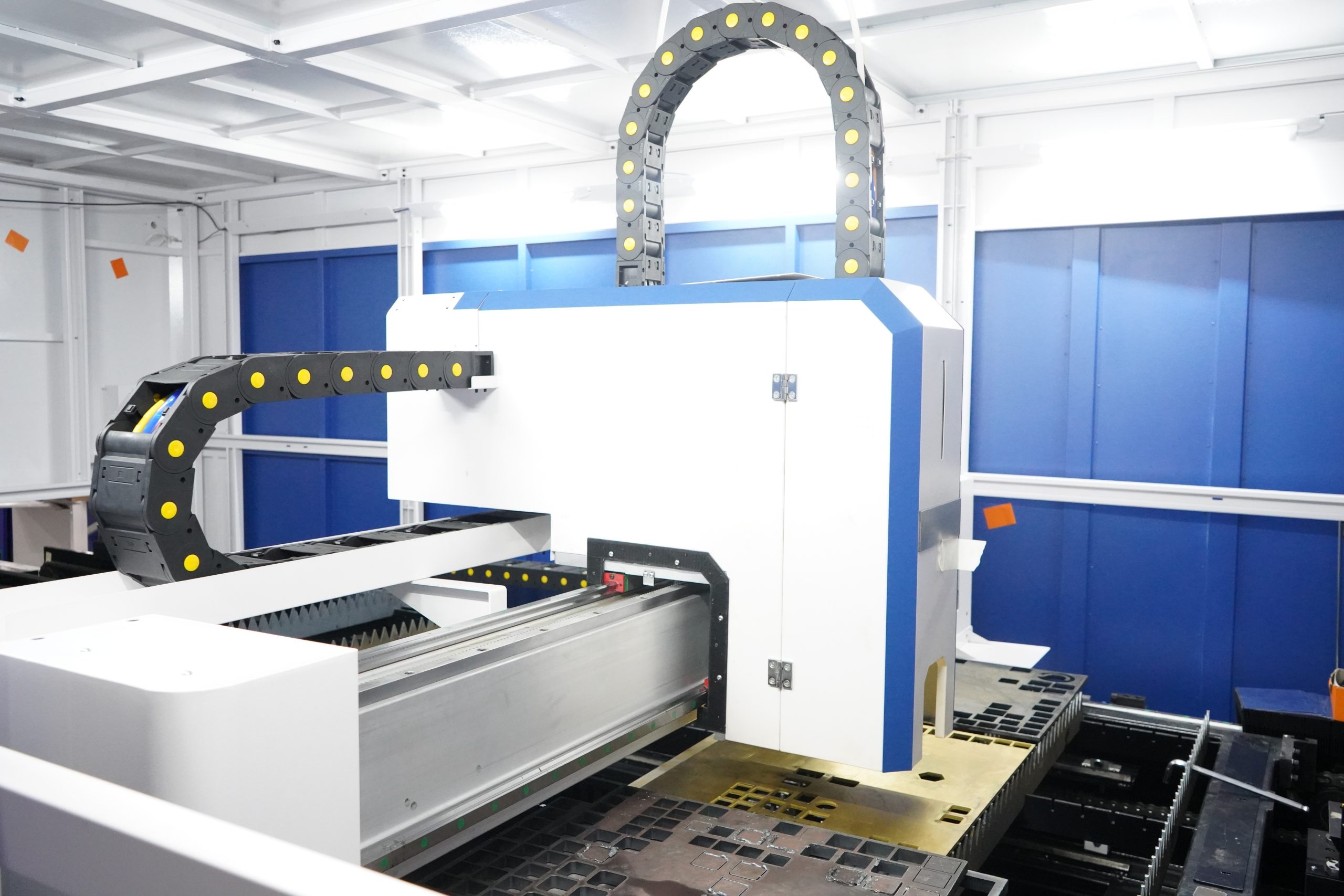

Diseño compacto con alimentación integrada, el control, y el sistema de enfriamiento, se adapta perfectamente al molde talleres con espacio limitado.

Rígido marco soldado con autógena con el alivio del estrés tratamiento garantiza la homogeneidad de la corte de precisión durante los largos de fabricación de molde de los procesos.

En tiempo Real de la perforación de ajuste que se adapta a una variedad de la base de molde espesores, evitando manual de recalibración.

Multi-eje de control inteligente soporta intrincado contorno de caminos esencial para el complejo molde de la cavidad de moldeo.

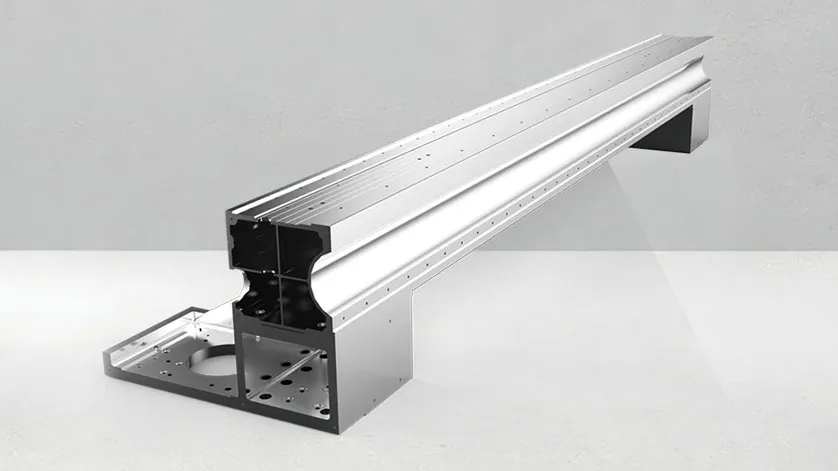

De aluminio de alta resistencia de la viga ofrece un movimiento suave y de alta velocidad de corte en la herramienta de acero duro y aleaciones.

Armario cerrado separa fuertes y débiles de las corrientes, la reducción de EMI riesgos cuando el procesamiento de componentes de alta precisión.

Uno-haga clic en el borde de la alineación mejora la precisión de grabado en el molde de los números y la estructura fina de los contornos.

De alta potencia de la fuente de láser proporciona un suave, libre de rebabas cortes en capas gruesas de acero insertos para moldes de inyección.

Smart anti-sensores de colisión proteger caro molde espacios en blanco durante la operación de alta velocidad.

Modular de la mesa de trabajo permite una rápida sustitución de los útiles de sujeción para los diferentes componentes del molde.

Libre de humo de doble zona de sistema de ventilación mantiene la visibilidad cuando la corte de acrílico transparente o el moho cubre.

Mínima zona afectada por el calor reduce post-mecanizado y protege tolerancia dimensional de piezas de precisión.

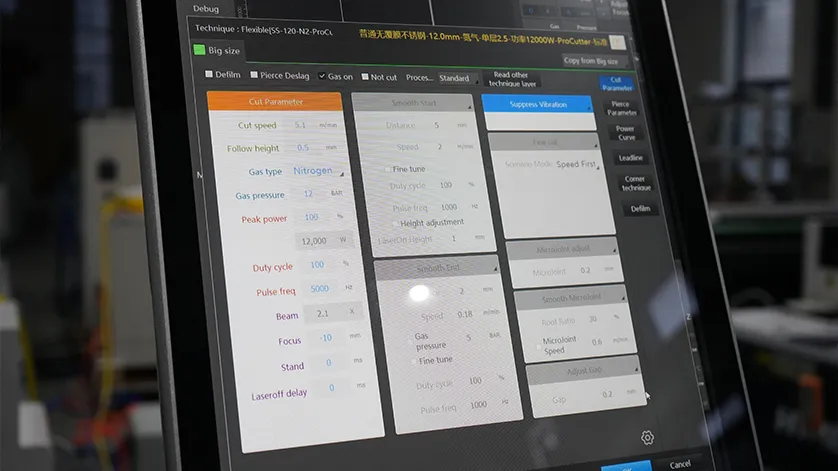

El sistema del CNC de 21,5" pantalla táctil permite una fácil programación de moho parte de las bibliotecas y la optimización del trazado.

Soporta lote de anidación de las placas de molde para maximizar el uso de materiales y reducir los residuos.

Soporta lote de anidación de las placas de molde para maximizar el uso de materiales y reducir los residuos.

Su estructura minimalista, combina su cuerpo principal, armario eléctrico, sistema de control, compresor de aire, generador de láser, y enfriador de agua en una sola, así como a reducir los costes de espacio y mejorar el taller de utilización.

Esta máquina funciona de manera estable y tiene un buen rendimiento dinámico, así como para servir a los usuarios por un largo tiempo en ultra-alta energía.

| MODELO | P12025 | P10025 | P8025 | P6025 | P4020 | P3015 |

| Formato de procesamiento de | 12000m m*2500mm | 10000mm*2500mm | 8000m m*2500mm | 6000mm*2500mm | 4000mm*2000mm | 3000mm*1500mm |

| la aceleración | 1.0 G | 1.0 G | 1.5 G | 1.5 G | 1.5 G | 1.5 G |

| Peso total | 25000kg | 20000kg | 16000kg | 12000kg | 8000kg | 5500kg |

| de la cabeza del láser | 6KW a continuación:RAYTOOLS 10KW y sobre:PORAD |

6KW a continuación:RAYTOOLS 6KW y sobre:Alemania Precitec |

RAYTOOLS | |||

| Fuente de láser | MAX/Raycus/IPG | |||||

La opción confiable para la reducción de los costes con la operación fácil

Doble plataformas de intercambio disponible para guardar el tiempo de espera para la carga y descarga

Adoptar hueco de la máquina herramienta y el grafito en forma de placas de prevención de incendios

Aviación-grado AL haz de alta resistencia, lo que permite su corte en varias formas a alta velocidad

Totalmente estructura cerrada, con tapa en la puerta de aire y el polvo de la cortina para la seguridad y la protección ambiental

Utilizamos integrado de componentes electrónicos y precisión carril de guía y bastidores (100%) para permitir una alta aceleración (2,8 G) y la precisión de posicionamiento (±0,05 mm).

Mantenga la máquina herramienta indeformable y continuo a alta temperatura, incluso después de largo tiempo de uso debido de ir a través de los 7 procesos estándar igual a 600° alta recocido

Toda la ronda de vigilancia sin zona muerta, haciendo de corte más seguro

Empleamos inteligente basada en bus del sistema del CNC equipado con pantalla de 21,5 pulgadas de pantalla táctil. Es fácil de instalar y depurar, gracias a su rápido y transmisión de datos rápida, baja tasa de fracaso y de fácil mantenimiento.

Rápido para perforar a través de gruesas placas de alta calidad

Como uno de los modelos clásicos, la serie P de fibra de corte por láser de la máquina se utiliza principalmente para materiales metálicos, tales como acero inoxidable, acero al carbono, galvanizado, latón, aluminio, y varias placas de aleación de

The HWlEiC P series provides cost-efficiency and high performance for various industries looking to upgrade metal processing methods and improve competitiveness.

Por favor, rellene el siguiente formulario para solicitar un presupuesto,catálogo,o en la consulta técnica.Nuestro equipo se pondrá en contacto con usted dentro de 24 horas.

Le responderemos dentro de 24 horas. Si por caso urgente, por favor agregar WhatsApp/WeChat: +86 15589913375. O llame al +86 15589913375 directamente.

*Hemos de respetar su confidencialidad y toda la información están protegidos.

Sólo utilizaremos su información para responder a su consulta y nunca envía correos electrónicos no solicitados o mensajes promocionales.

Final de la dinámica y la eficiencia

La durabilidad y fiabilidad

Actualizado precisión y exactitud

Inteligente y fácil de utilizar

La seguridad y salud de la

Versátil automatización