Industry Trends

Precision, Automation, and Diversification Define the Future

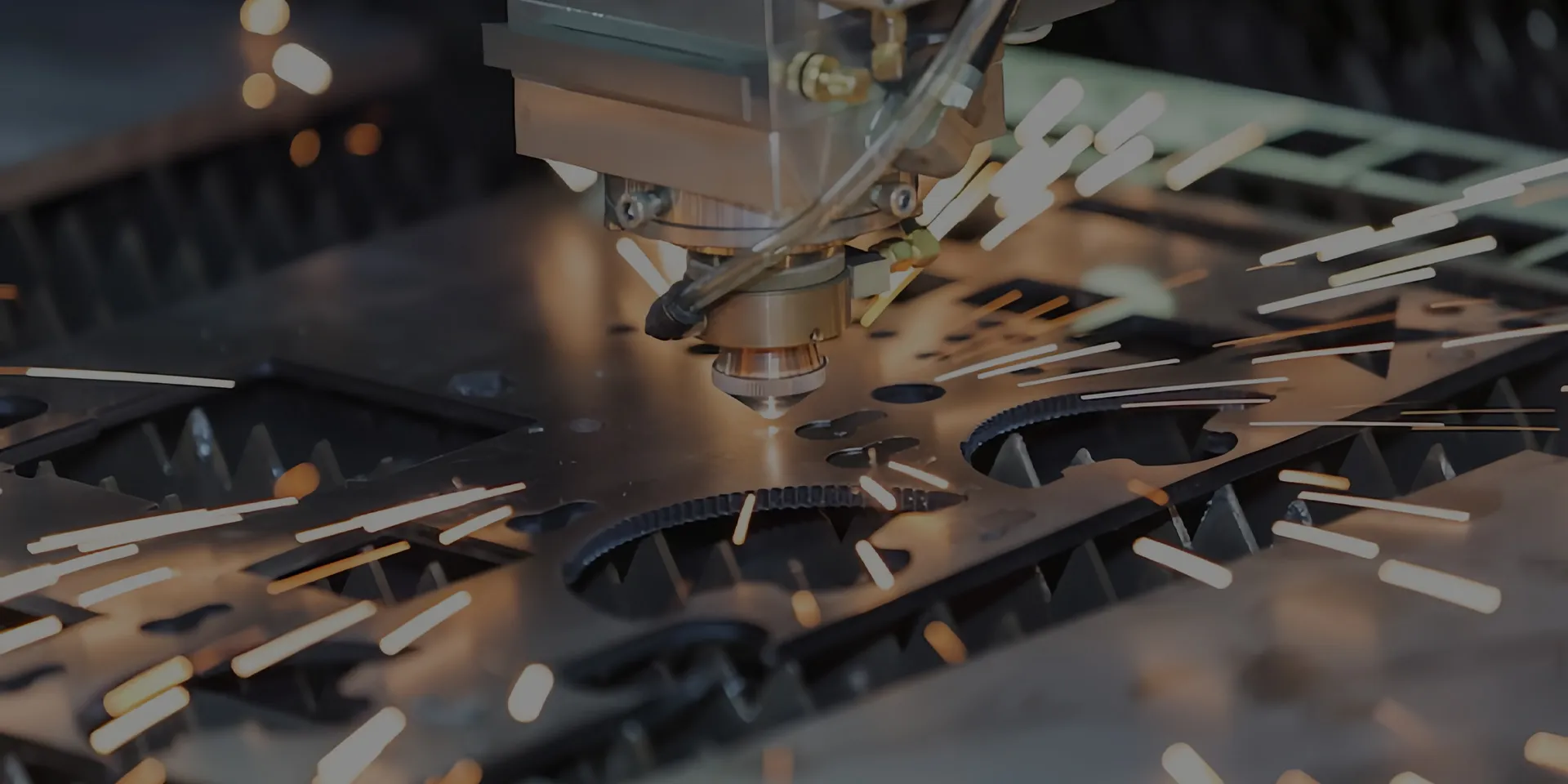

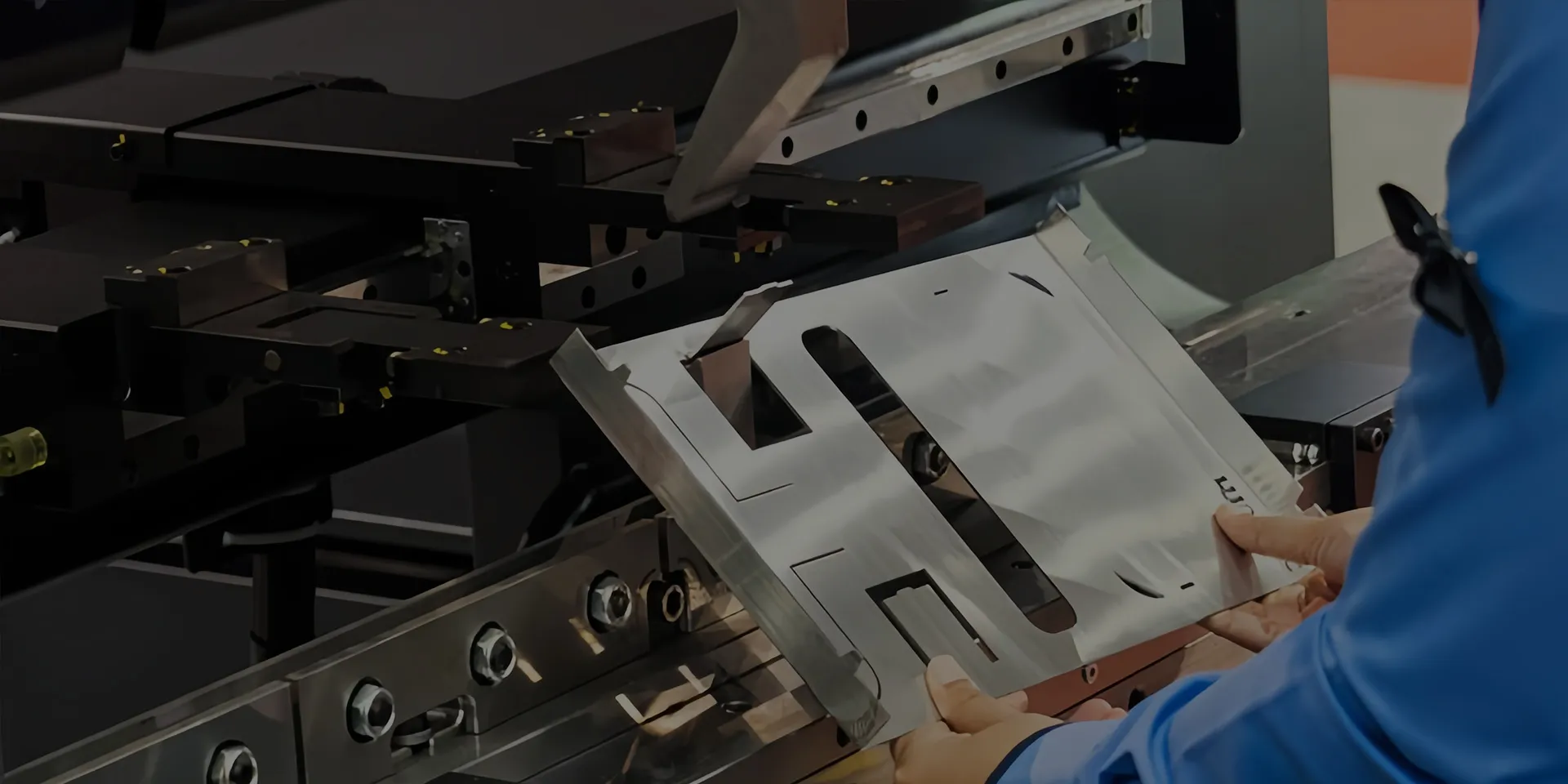

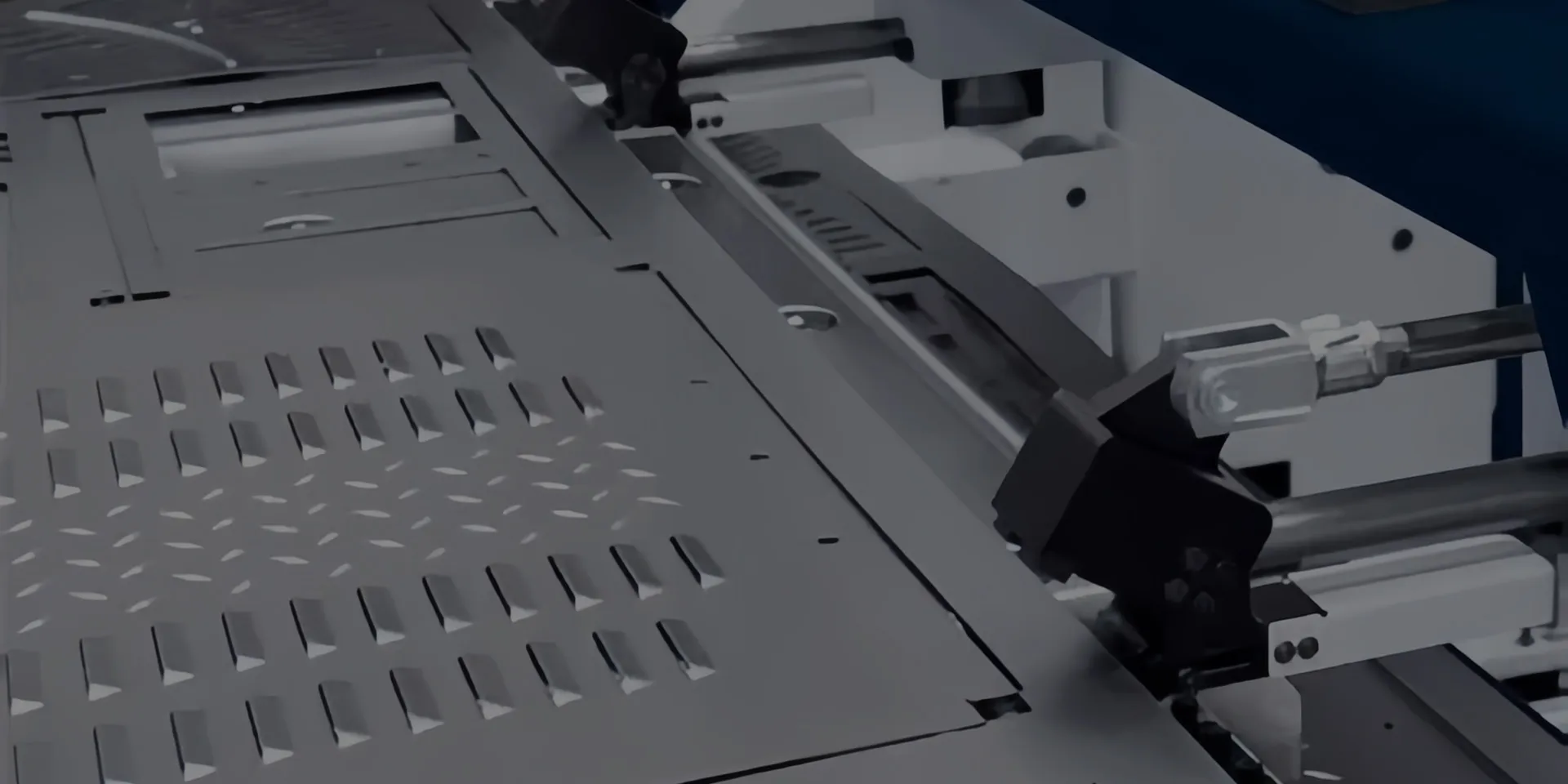

The sheet metal processing industry is undergoing a rapid shift toward high-precision, flexible, and intelligent manufacturing. With growing demand in automotive, appliances, electrical enclosures, cabinets, and construction, manufacturers must handle multi-material processing (e.g., stainless steel, aluminum, copper) while improving throughput and maintaining tight tolerances. Trends such as modular fabrication, CNC-controlled systems, laser-based processing, and smart factory integration are now essential for staying competitive.