Tube Laser Cutting Machine: CNC Tube Lasers for High-Precision Tube Processing

A tube laser cutting machine is a CNC laser cutting machine designed to process round, squ…

learn more

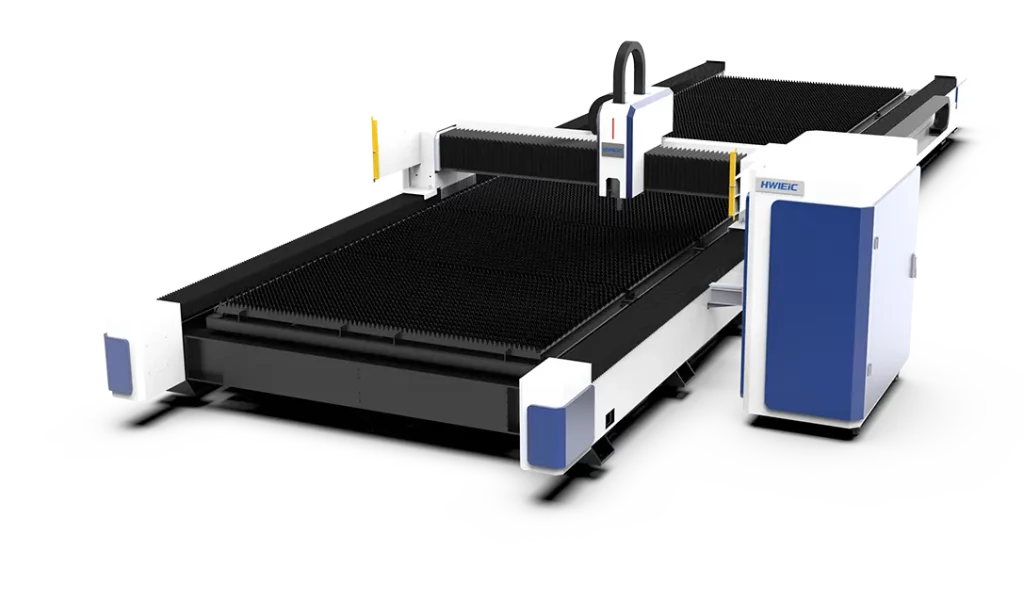

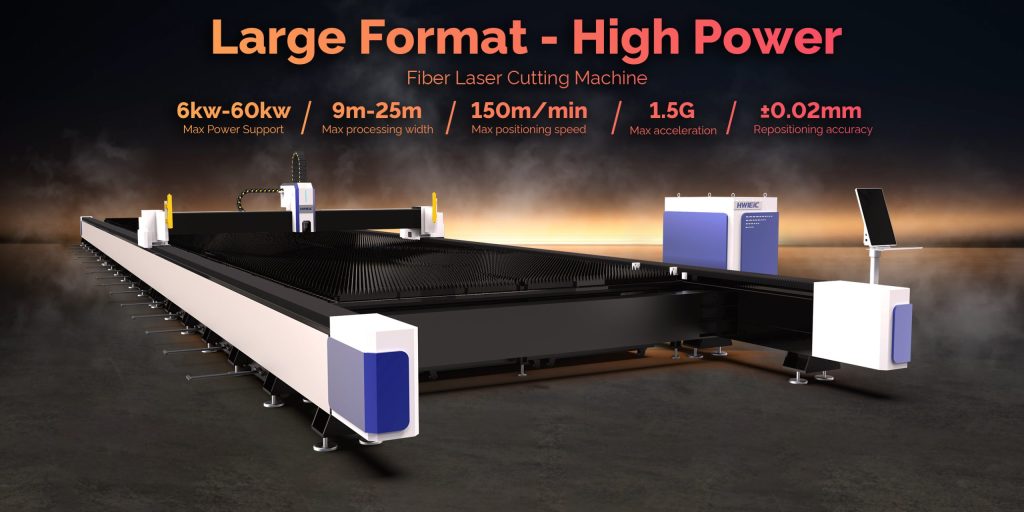

As manufacturing scales up, traditional cutting machines struggle with large materials, tight tolerances, and rising efficiency demands. Delays, waste, and rework slow production. A modern industrial laser cutting machine solves these problems with large format capability, speed, and precision.

An industrial laser cutting machine uses a high-powered laser system to cut large-format metal and non-metal materials with speed and accuracy. Compared with conventional cutting machines, large format laser cutting offers higher precision, cleaner edges, and greater flexibility for modern manufacturing and advanced industrial applications.

An industrial laser cutting machine is a category of cutting machines designed for continuous, high-load industrial use. Unlike entry-level laser equipment, these machines are built for large format processing, long operating hours, and demanding production environments.

At the core of the system is a powerful laser source that delivers energy through a focused laser beam. This enables accurate cutting and engraving on large work pieces while maintaining stability and reliability. Industrial laser cutting is widely applied in metal fabrication, textile processing, and large material cutting where traditional methods fall short.

For manufacturers seeking consistent performance and long-term value, industrial laser cutting machines represent a critical production asset.

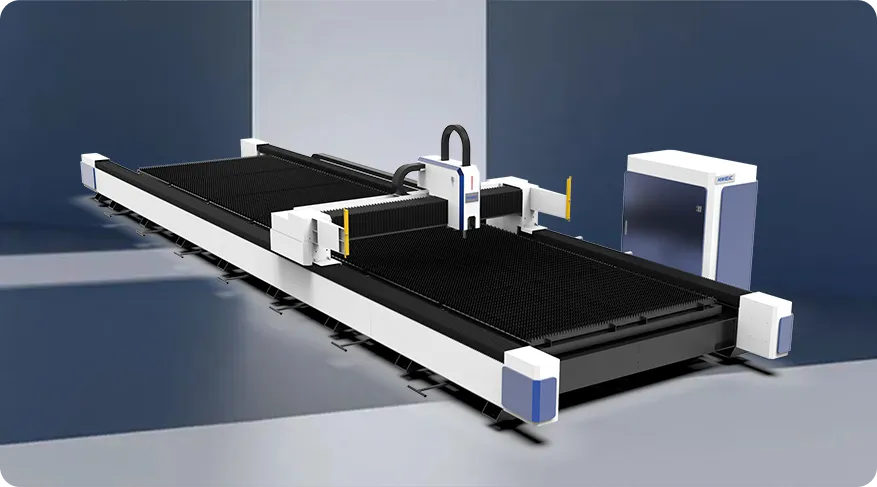

As product sizes grow, manufacturers increasingly require large format laser cutting to process oversized sheets and panels in a single operation. Traditional cutting machines often require repositioning or secondary processing, which reduces efficiency.

By eliminating multiple setups, the laser cutting machine increases productivity and consistency. This is why large format laser cutting has become standard in machines and industrial manufacturing environments.

Choosing the right laser type is critical when configuring an industrial laser cutting machine.

Fiber laser technology dominates metal cutting applications. Fiber laser cutting machines offer:

A large format fiber laser system is ideal for sheet metal processing where accuracy and throughput are essential.

A CO2 laser or format CO2 laser is often used for acrylic, textile, and non-metal materials. Large format CO2 laser cutting machines excel at cutting and engraving organic materials with smooth edges.

Understanding co2 and fiber laser differences helps manufacturers choose the optimal laser cutting solution for their materials and applications.

Large format laser cutting machines are widely used in:

Automotive and transportation manufacturing

Aerospace and heavy equipment

Sheet metal fabrication

Textile and signage industries

In these industrial applications, machines are capable of processing large materials efficiently and accurately. Laser cutting is especially suitable for cutting complex shapes in large work pieces where traditional cutting tools struggle.

When selecting an industrial laser cutting machine, manufacturers should evaluate:

Rather than focusing only on price, decision-makers should consider long-term stability, reliability, and service support. A well-configured large format laser system delivers sustained value over many years.

As manufacturing moves toward larger components and higher efficiency, large format laser cutting machines play a central role. Their ability to combine precision, speed, and flexibility makes them essential for modern production.

An industrial laser cutting machine offers:

For enterprises focused on intelligent manufacturing, laser cutting is not just a tool—it is a strategic capability.

What is a large format industrial laser cutting machine?

It is a laser cutting machine designed to process oversized materials with high precision and stability.

Which laser type is better for large format cutting?

Fiber lasers are ideal for metal cutting, while CO2 lasers are better for acrylic and textile materials.

Is automation important for large format laser cutting?

Automation improves efficiency, safety, and consistency, especially in high-volume production.

What industries use large format laser cutting?

Automotive, aerospace, sheet metal fabrication, textile, and heavy industry widely use large format laser cutting machines.

A large format industrial laser cutting machine is more than cutting equipment—it is a foundation for efficient, precise, and scalable manufacturing. By combining advanced laser technology, modular design, and intelligent control, these machines meet the evolving demands of modern industry.

For manufacturers seeking stability, performance, and long-term reliability, large format laser cutting offers a proven path forward.

A tube laser cutting machine is a CNC laser cutting machine designed to process round, squ…

learn more

An industrial laser cutting machine uses a high-powered laser system to cut large-format m…

learn more

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 15589913375. Or call +86 15589913375 directly.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.

Ultimate dynamics and efficiency

Durability and reliability

Upgraded precision and accuracy

Intelligent & ease of use

Safety & healthy

Versatile automation