Performance based on robustness and, above all, reliability.

Fast and efficient, wide processing range:automatic laser welding machine hasconcentrated energy, high-effciency andhigh-speed welding, smooth and beautifuwelds, and reduce subsequent grindingprocesses.

Robotic laser welding machine - Features & Configuration

Collaborative robots can effectively copewith laser welding operations, helping toachieve flexible, efficient and free weldingprocesses.

6-Axis Collaborative Robotic Arm

Flexible laser welding with human-robot collaboration. Enhances efficiency, reduces labor costs, and solves the skilled welder shortage — helping you boost capacity and profits.

Auto Laser Welding Head

Fast, precise, and wide-range welding. Concentrated energy ensures high-speed, high-quality welds with minimal post-processing. Ideal for clean and smooth seams.

Versatile Laser Options

Choose from top brands: Raycus, Reci, Max, or IPG. High photoelectric conversion guarantees stable power and excellent welding performance. Configurable to fit your project needs.

Mini Handheld Laser Welder With Robust, Safe, Essential

Core Performance & Structural Advantages

-

Compact and portable design, 75% smaller in size, easy for one person to carry

-

Built-in universal wheels for effortless movement in tight spaces

-

Integrated laser head with dustproof sealed housing for longer lifespan

-

Maintenance-free air-cooling system—no water tank, no pump, no coolant required

-

Operates reliably from -10°C to 40°C, with humidity below 70%

-

CE-certified core components ensure long-term electrical safety

-

4-in-1 functionality: welding, cutting, rust removal, and cleaning

-

Smart control system enables easy switching between processing modes

-

Compatible with Raycus, Max, Reci, IPG and other top laser brands

-

Ideal solution for small workshops and outdoor welding jobs

-

High photoelectric conversion efficiency with stable laser output

-

Minimal heat-affected zone, delivering smooth and clean weld seams

-

3–10× faster welding speed compared to traditional methods

-

Lightweight laser gun (≤0.7kg), fatigue-free operation for long hours

-

No filler wire or consumables required, minimizing operating costs

-

Replaces up to two skilled welders, significantly reducing labor costs

-

Supports a wide range of metals: stainless steel, carbon steel, aluminum, and more

Flexibility and efficiency

Ensure safety, maximize material usage, and streamline operations for superior productivity and cost savings.

Why hwieic ?

- Ultimate dynamics and efficiency

- Durability and reliability

- Upgraded precision and accuracy

- Intelligent & ease of use

- Safety & healthy

- Versatile automation

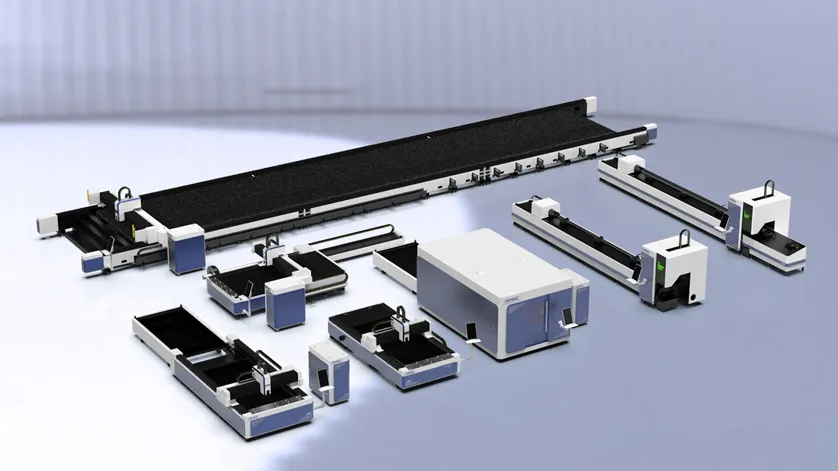

Product Performance

This machine features automated laser welding technology designed for production lines, offering high efficiency and precision. Explore its advanced robotic capabilities and applications today.

| Model | HJ-R-1000 | HJ-R-1500 | HJ-R-2000 | HJ-R-3000 |

| Laser Power | 1000w | 1500w | 2000w | 3000w |

| Operating Mode | Continuous / Modulation | |||

| Power Requirements | 220V/ 50Hz/60Hz | 380V/50Hz/60Hz | ||

| perating Temperature | 15-35℃ | |||

| Working Humidity | <70% No condensation | |||

| Max. Welding Thickness | 0.5-2.5mm | 0.5-3.5mm | 0.5-4mm | 0.5-8mm |

| Welding Line Requirements | ≤0.5mm | |||

| Max. Welding Speed | 120mm/s | |||

| Machine Size | 1300*1200*800mm | |||

| Machine Weight | 200kg | |||

Product Performance

The reliable choice for lower costs with easy operation

- 6-axis human-robot collaboration robotic arm

- Automatic laser welding head

- Various lasers Laser Options

6-axis human-robot collaboration robotic arm

Collaborative robots can effectively copewith laser welding operations, helping toachieve flexible, efficient and free weldingprocesses.

Reduce labor and labor consumption.

Solving the shortage of skilled welders

increases production capacity and profits

Automatic laser welding head

Fast and efficient, wide processing range:automatic laser welding machine hasconcentrated energy, high-effciency andhigh-speed welding, smooth and beautifuwelds, and reduce subsequent grindingprocesses.

Various lasers Laser Options

Using well-known brand laser generators(Raycus/Reci/Max/IPG), the high

photoelectric conversion rate ensures laselpower and makes the welding effect better.W/e can desian different confqurations tomeet customer needs

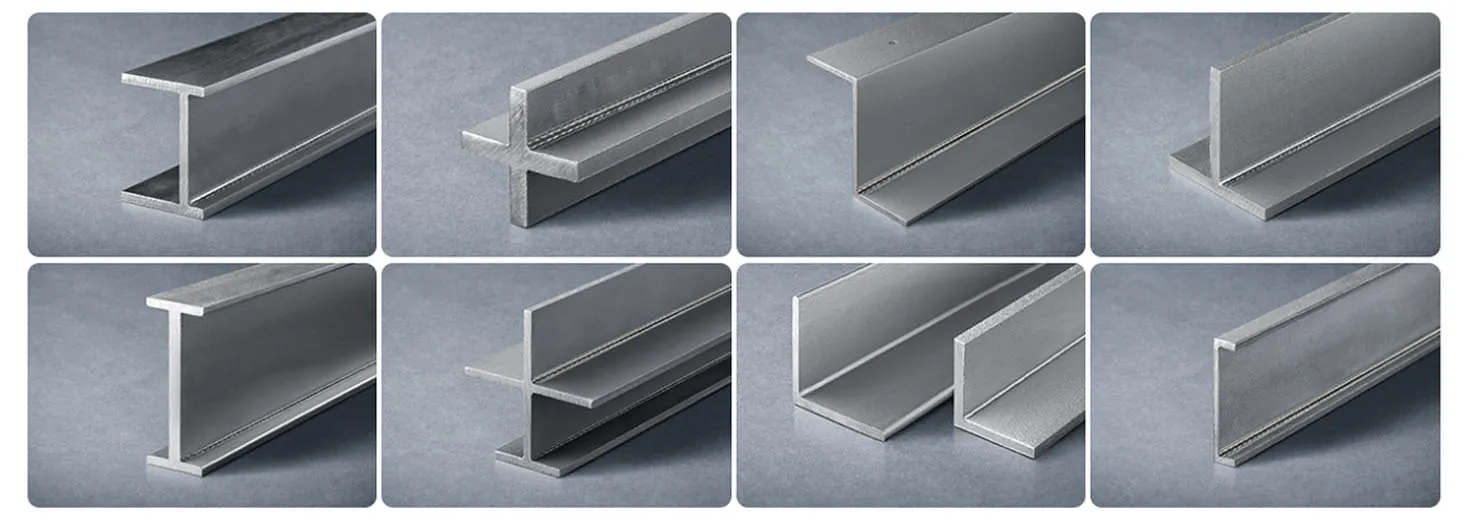

High Quality Results In All Sheet Thickness

HJ-R series laser welding machine is mainly used for welding carbon steel, stainless steel, aluminum and other metal materials.

Customer Visit

The HWlEiC Tseries provides cost-efficiency and high performance for various industries looking to upgrade metal processing methods and improve competitiveness.

Request A Quote

Please fill out the form below to request a quote,catalog,or technical consultation.Our team will get back to you within 24 hours.

Get a Quote

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 ******,. Or call +86 ****** directly.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.

Products

POWER TOOLS

Ultimate dynamics and efficiency

Durability and reliability

Upgraded precision and accuracy

Intelligent & ease of use

Safety & healthy

Versatile automation