Laser for cutting metal technology has good precision and efficiency. Yet, such a powerful technology also requires appropriate safety measures. This blog explores the important role of guards in laser cutting machines. Their advantages and situations where they must be used are analyzed.

1.What Are Laser for Cutting Metal Guards and What Do They Do?

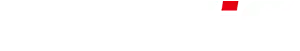

Laser cutting machine guards are a protective barrier. It protects the operator and the environment from direct and indirect hazards associated with the laser cutting process. These guards are usually made of durable light-transmitting materials. While blocking harmful laser radiation, they also provide visibility. The laser guards currently available on the market are generally integrated into the machine and are called closed fiber laser cutting machines.

Function:

Safety protection. The main function of these guards is to protect the operator from high-intensity laser beams. Because high-intensity laser beams can cause serious damage, especially to the eyes and skin. Confining the laser to a controlled environment can prevent accidental exposure to the laser beam.

Environmental protection. Machine guards also play an important role in maintaining a clean and safe working environment. They help control smoke, fumes, and particulate matter generated during the cutting process and prevent these potentially harmful byproducts from spreading to the surrounding area.

2. When Are Guards Required?

Regulatory requirements

Many countries have strict regulations requiring the use of safety guards on laser cutting machines. These laws are designed to ensure workplace safety and are often enforced during inspections and audits. Compliance is thus not only a safety measure, but also a legal need.

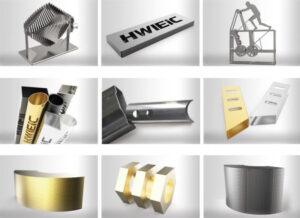

High-risk materials

Guards are essential when cutting reflective or high-risk materials. They prevent the beam from reflecting back to the operator or other unintended directions, potentially causing damage or injury.

Large-scale production environments

Guards are essential in environments where many machines are running simultaneously or where the scale of production requires continuous operation. They reduce overall workplace risk. Not only protecting the machine operator, but also other personnel who may be close to the laser cutting area.

3. Situations Where Protective Gear May Not Be Required

Low-power applications For laser cutting machines operating at lower power levels, the risks associated with the laser beam may be greatly reduced. In these cases, protective gear may not be required if the intensity of the laser is not sufficient to cause direct injury or the material being cut does not produce hazardous byproducts. However, an assessment should always be made to ensure compliance with safety standards.

4. Other Benefits of Using Guards on Laser Cutters

Improved Precision and Efficiency

Guards also play a role in keeping the cutting environment clean and stable. Guards keep dust and debris away from the laser path and material surface, ensuring that the laser beam is not obstructed or scattered. This allows for more precise cutting and less waste.

Prolong Equipment Life

Guards help protect the sensitive parts of the laser cutting machine from dust, debris, and accidental contact. This protection is essential to keep the machine in optimal condition, extend its life, and reduce maintenance costs.

Professional Image

Incorporating safety measures such as guards can enhance a company’s professional image. Demonstrating a commitment to safety can win the trust of customers and regulators and show that the company is a responsible and reliable entity in the industry.

5.Options for Purchasing And Installing Protective Covers

Integrated design

Many modern laser cutting machines have protective covers designed as an integral part of the machine. This design is usually more sophisticated and ensures greatest safety and efficiency. In this case, the protective cover and laser cutting machine are purchased as a whole and cannot be separated.

Separate accessories

For some older or special-purpose models, protective covers may be sold separately as accessories. Users can choose the appropriate protective cover model and material according to their needs and perform post-assembly.

Customization options

In some cases, users can choose to customize the protective cover. Customized protective covers can ensure a perfect fit for specific models and meet the needs of specific working environments.

When purchasing a laser cutting machine, it is important to consider the type and characteristics of the protective cover. The right protective cover not only improves work safety, but also ensures a smooth and clean cutting process while extending the life of the machine.