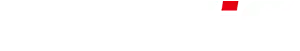

As an indispensable and efficient tool in the modern manufacturing industry, laser cutting machine has been widely used in many industries for its high precision and high efficiency cutting ability. From automobile manufacturing to metal processing, from sheet metal processing to architectural decoration, laser cutting machines have revolutionized different industries with their unique advantages. In this paper, we will explore the application of laser cutting machines in different industries and case studies to reveal their wide applicability and significant economic benefits.

In order to better demonstrate the application of laser cutting machines in different industries, we will then analyze several specific cases. These cases will cover the manufacturing industry, metal processing, medical equipment, textiles and other industries, in order to demonstrate the advantages and value of laser cutting machine to the actual application results.

First, the manufacturing industry

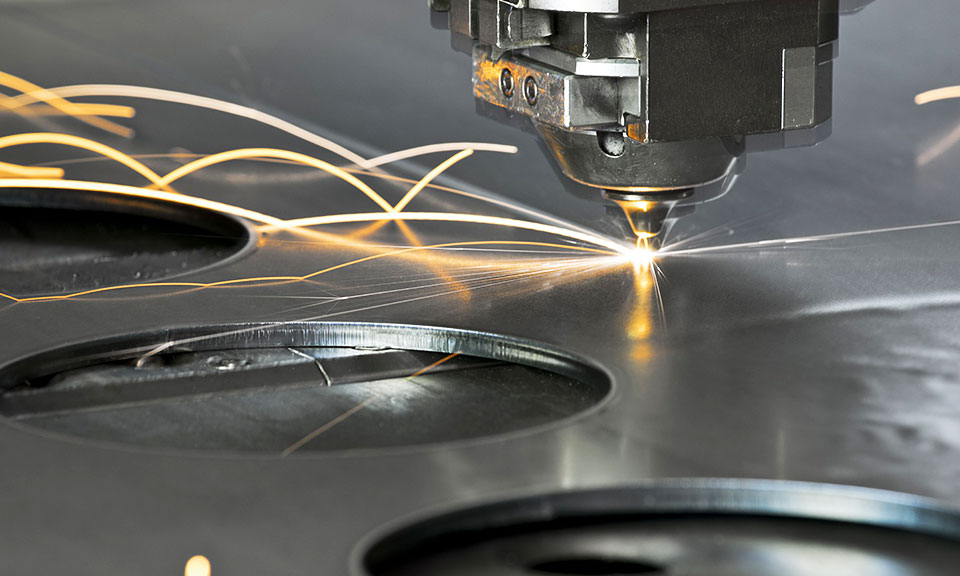

In the field of manufacturing, laser cutting machine by virtue of its high precision, high efficiency features, become an important tool for metal and non-metal materials processing. Take the automobile manufacturing industry as an example, laser cutting machine is widely used in the body, doors, windows and other parts of the cutting. Through precise control of laser power, cutting speed and focus position and other parameters, the laser cutting machine is able to realize the cutting of complex shapes, while ensuring the smoothness and precision of the cutting edge. According to statistics, after the adoption of laser cutting machine, the automobile manufacturing industry’s productivity increased by more than 30%, scrap rate reduced by 20%.

Case study: a well-known automobile manufacturers in the introduction of laser cutting machine, the body parts cutting experiments. Compared with the traditional cutting method, the laser cutting machine in the cutting speed increased by 50%, cutting accuracy reached within 0.1mm. At the same time, the laser cutting machine has a high degree of automation, reducing the time and cost of manual operation, making the production cost reduced by 15%.

Second, metal processing industry

In the metal processing industry, laser cutting machine also has a wide range of applications. Through the laser cutting machine, you can achieve a variety of metal materials such as steel, aluminum, copper and other fast, accurate cutting. In the aerospace field, laser cutting machine is used to cut aircraft parts, such as wings, fuselage, etc.. Its high precision and high efficiency have led to a significant improvement in the quality and performance of aerospace products. According to the survey, the production cycle of aerospace products has been shortened by 30% and the quality qualification rate has been increased by 10% after the adoption of laser cutting machine.

Case study: an aviation manufacturer introduced a laser cutting machine for cutting aircraft parts. In actual application, the laser cutting machine has shown excellent performance. Through precise control of laser parameters and material parameters, the laser cutting machine realizes high-precision and high-efficiency cutting operations. At the same time, the laser cutting machine has a high degree of automation, reducing the time and cost of manual operation, so that the production efficiency has been significantly improved.

Third, the medical equipment industry

In the medical equipment industry, laser cutting machine is used to manufacture artificial organs, medical equipment, dental orthodontic and other precision parts. The high precision and high stability of laser cutting machine makes the precision and reliability of medical equipment has been guaranteed. At the same time, the non-contact processing method of laser cutting machine avoids the deformation of materials and pollution problems, which ensures the health and safety of medical equipment. According to statistics, after adopting the laser cutting machine, the precision of medical equipment has been increased by 20%, and the qualification rate has reached more than 99%.

Case study: a medical device manufacturer uses laser cutting machine to manufacture dental orthodontic braces. During the manufacturing process, the laser cutting machine realizes high-precision and high-efficiency cutting operation by precisely controlling the laser parameters and material parameters. At the same time, the non-contact processing method of the laser cutting machine avoids the deformation and contamination problems of the material and ensures the hygiene and safety of the dental aligners. After adopting the laser cutting machine, the productivity of the enterprise has increased by 50% and the product qualification rate has reached 100%.

To summarize, laser cutting machine has a wide range of application prospects and significant application effects in different industries. With the continuous development of technology and the continuous expansion of application fields, laser cutting machine will play an important role in more industries.